Process for manufacturing high temperature fluent metal return circuit with composite material of SiC/SiC

A technology of liquid metal and composite materials, which is applied in the field of preparing high-temperature liquid metal circuits with SiCf/SiC composite materials, can solve the problems of long preparation period, low matrix densification rate, and large fiber damage, and achieves reduction of yield and radioactivity level, Improved energy conversion efficiency and less thermal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

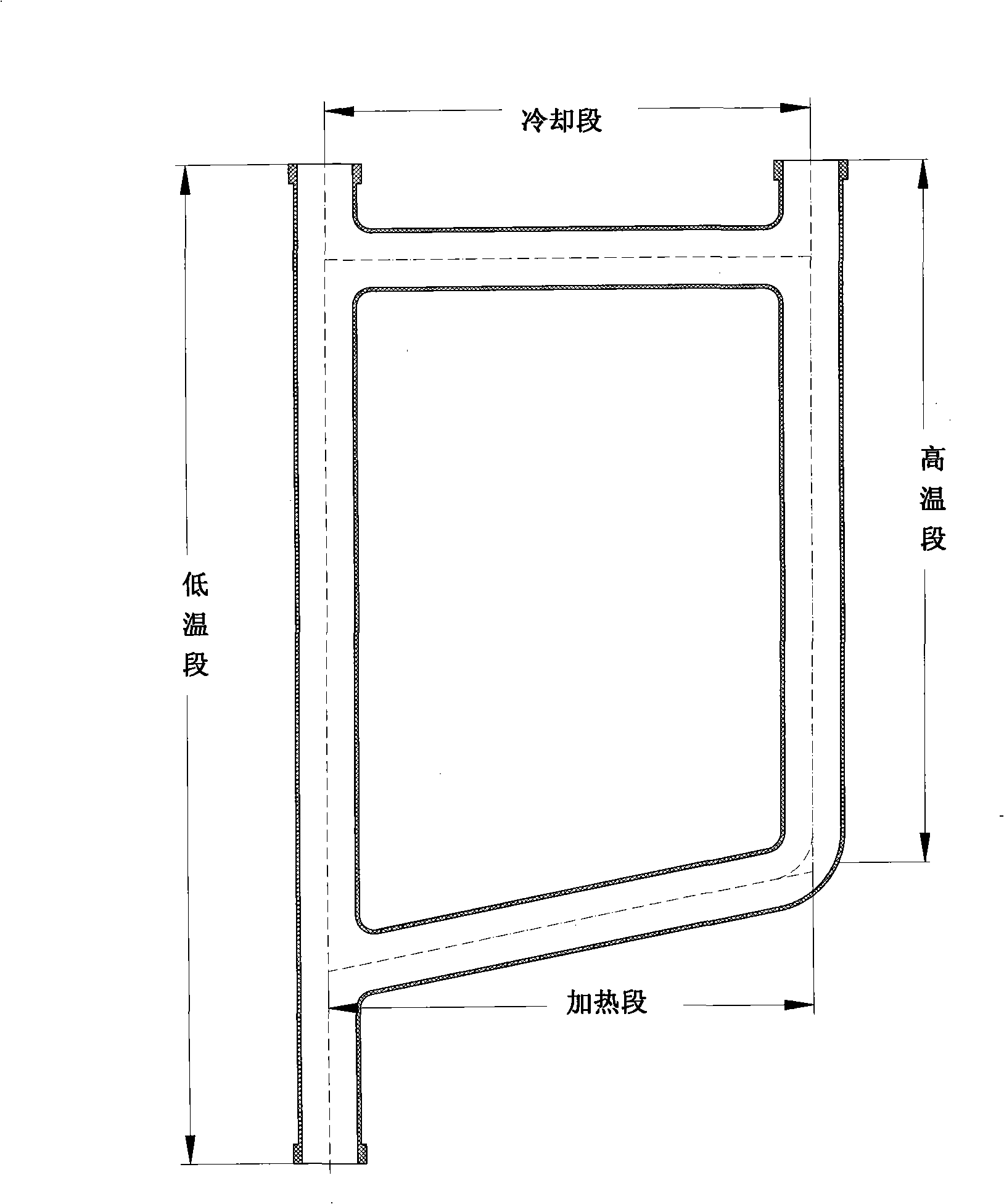

[0026] Such as Figure 2 ~ Figure 3 The high-temperature liquid metal circuit shown is prepared by the following method steps:

[0027] 1. Purchasing and customizing quartz core molds for preparing high-temperature liquid metal circuits. The shape of the core molds is as follows: figure 1 As shown, the silicon dioxide (SiO 2 ) mass fraction is 99.9%, and its surface roughness is less than 1nm;

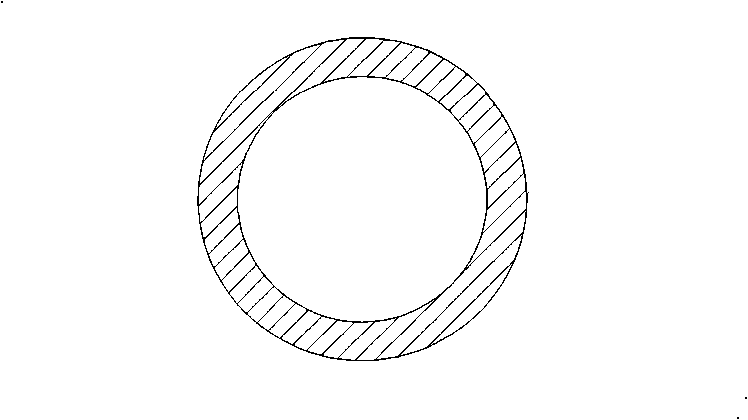

[0028] 2. Using SiC fiber as raw material and using three-dimensional weaving technology, SiC fiber woven parts are prepared on the above-mentioned quartz mandrel. After weaving, the outer surface is bound with SiC fiber to ensure that the fiber is tightly attached to the mandrel. The thread ends generated during the weaving process are not Stay on the inner surface to ensure the smoothness of the inner surface;

[0029] 3. Preparation of SiC by impregnation and pyrolysis of organic precursors f / SiC composite material circuit: the precursor used is polycarbosilane, polycarbosilane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com