Material-saving cigarette trade mark printing method

A technology for cigarettes and trademarks, applied in printing, printing machines, printing devices, etc., can solve problems such as waste and waste of raw materials, and achieve the effect of saving resources and preventing fogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

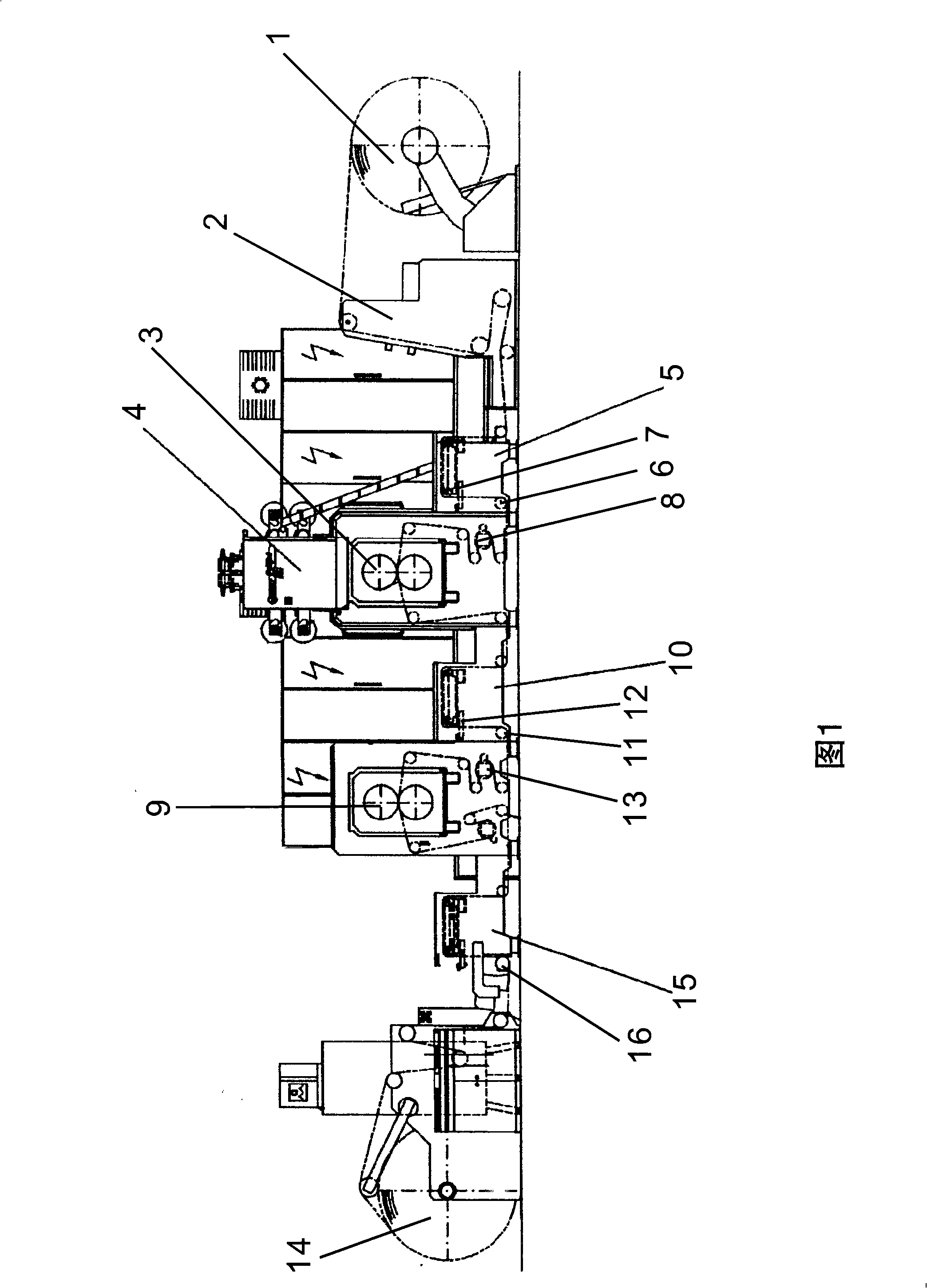

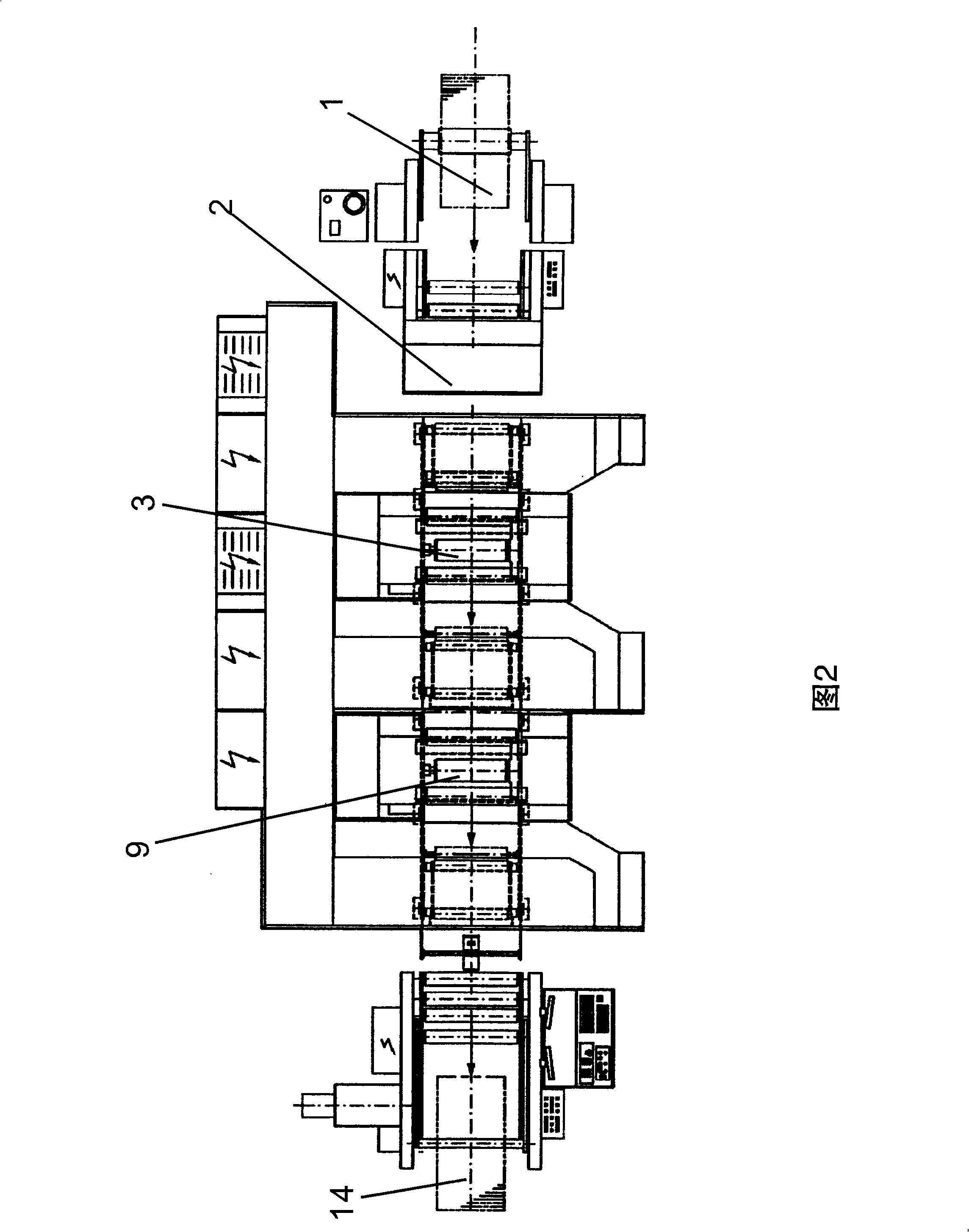

[0017] The process and equipment of hot stamping or hot holography are the core process and equipment of the present invention. The upstream printing process just prints a register mark line on each section of the paper. In the downstream die-cutting process, the die-cut sleeve The quasi-working principle is the same as the registration working principle in the bronzing process, so the process and equipment of the bronzing process of the present invention are described in detail as follows in conjunction with the accompanying drawings:

[0018] In Figure 1 and Figure 2, the paper printed with the registration mark line enters the paper changing table 2 from the unwinding roll 1, and in the hot stamping unit, there is a pair of hot stamping cylinders 3, and there are layout inserts on the hot stamping cylinders 3 , there is an anodized aluminum retractable device 4 on the upper part of the hot stamping cylinder 3, and a jumping roller is installed on the anodized aluminum retrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com