Powder spraying system for external integral container

A container and powder technology, applied in the field of spraying systems, can solve the problems of complex procedures, easy to scatter, and not being recycled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

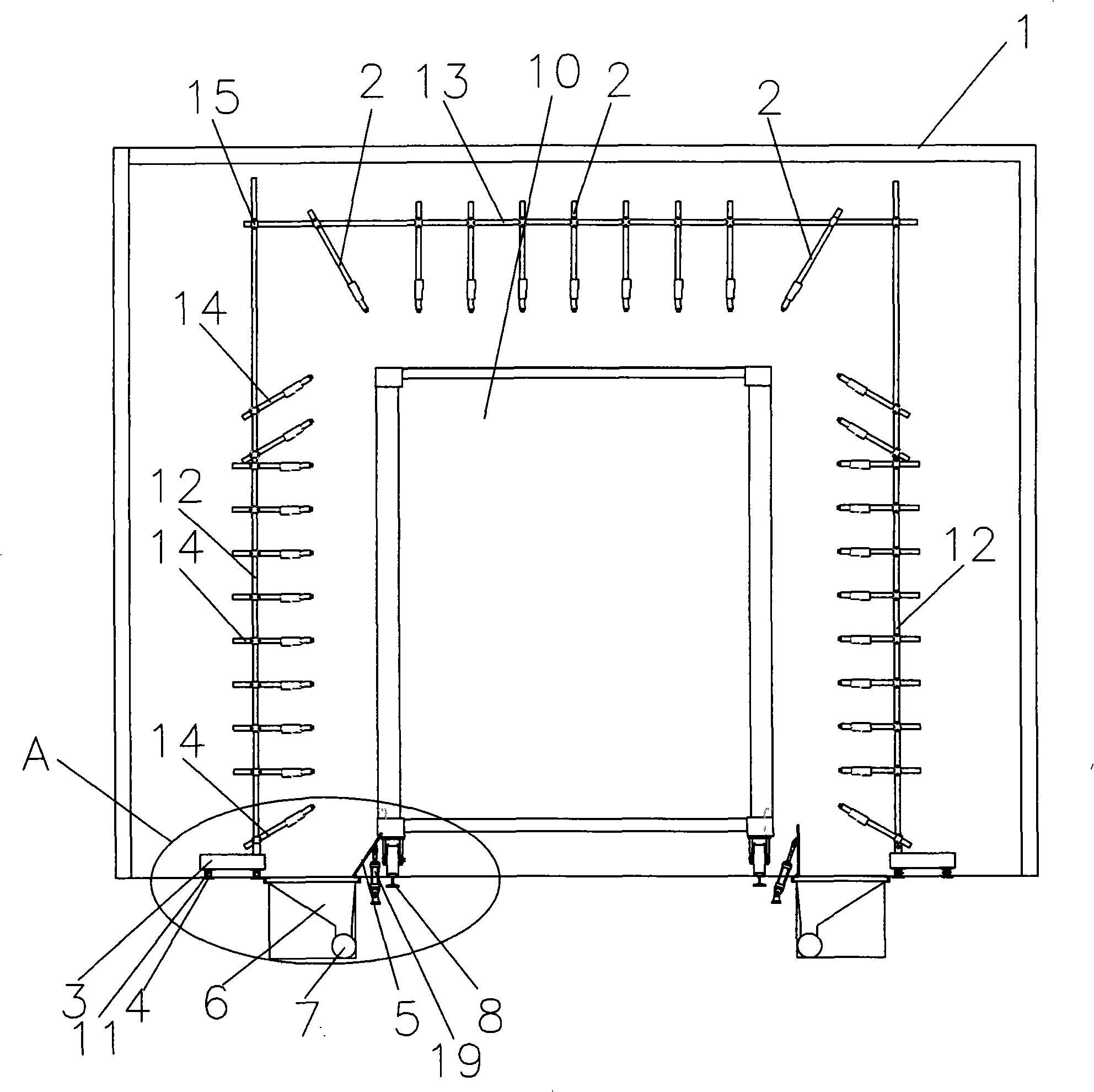

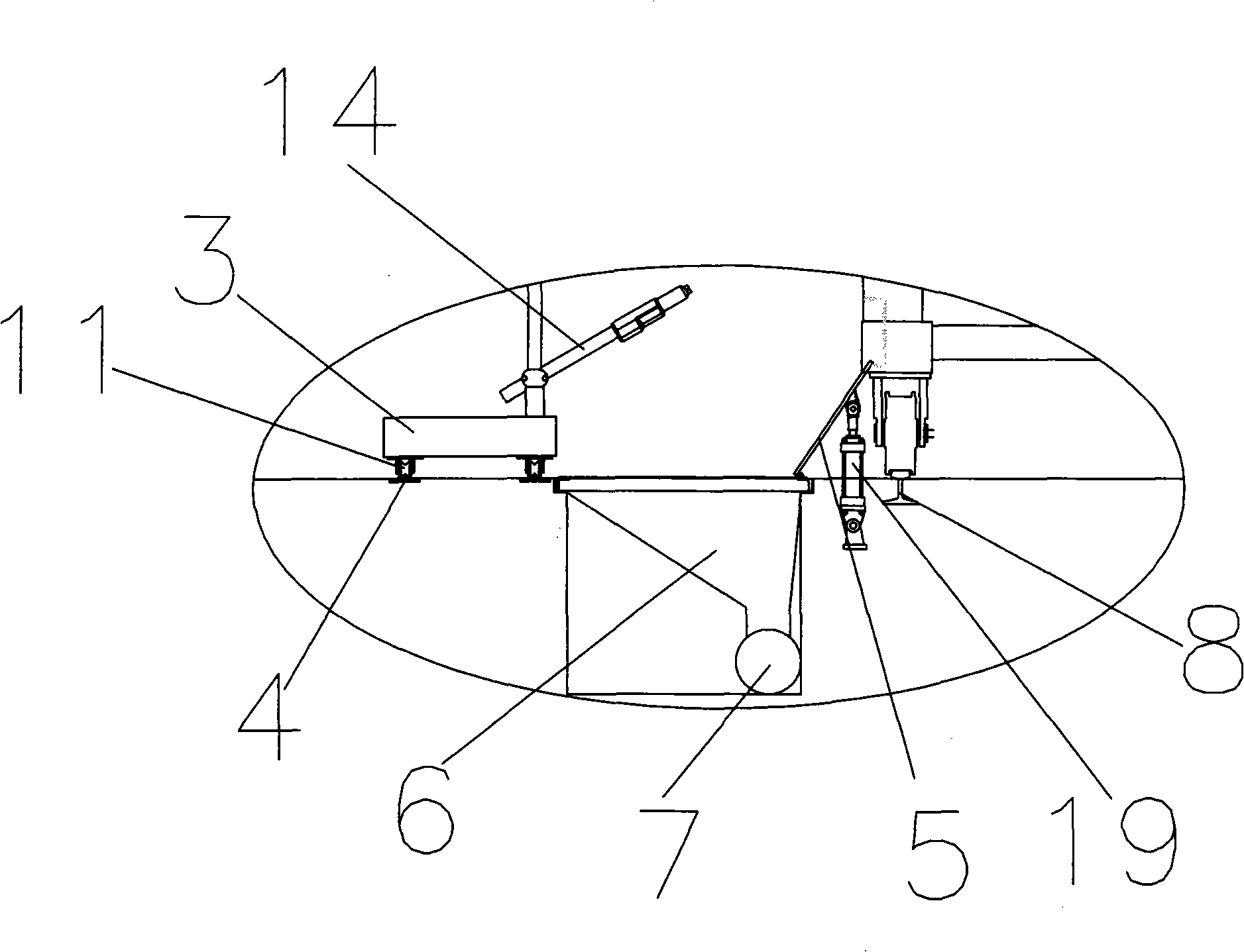

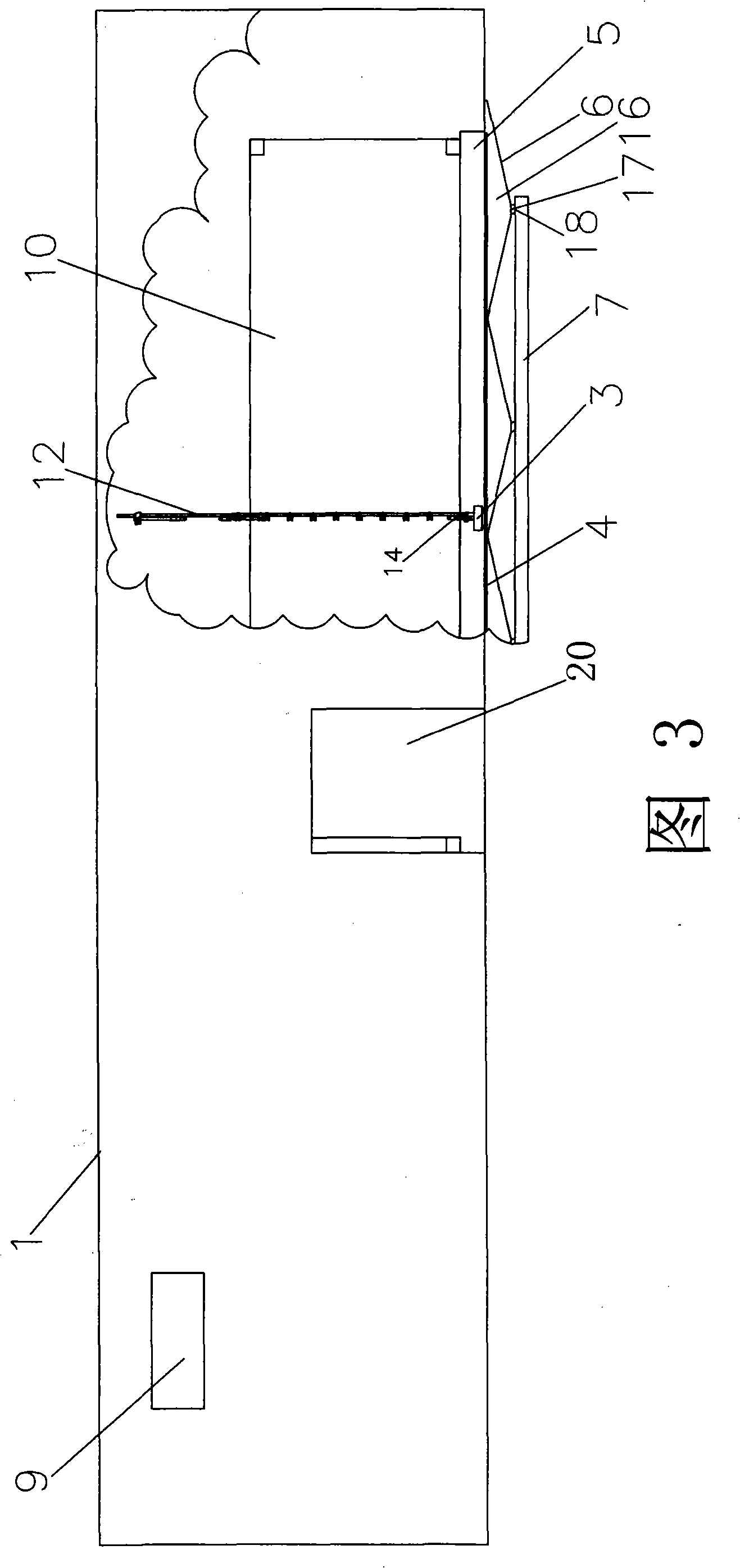

[0022] Example: such as figure 1 , figure 2 As shown, the overall powder spraying system outside the container box includes a powder spraying room 1, a power mechanism, and a powder recovery system. The powder spraying room 1 is in the shape of a cuboid. , go out, on the ground in powder spraying room 1, be provided with container delivery track 8, the main purpose of powder spraying room 1 is to isolate the spraying area, make overspray powder easy to recycle and reuse, and the powder that floats does not pollute surrounding environment. The width of the entrance and exit doors of the powder spraying room is about 100mm larger than the width of the container, and the height of the entrance and exit doors is about 50mm higher than the top of the super-high container when it is walking on the container transportation track, so that the container will not be in contact with the entry and exit. 1. Collision occurs when going out, and the gap between the box and the door is redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com