Multi-stage molecular distillation continuous depickling technique for oil and fat with high acidity number

A high acid value oil, molecular distillation technology, applied in the production/processing of edible oil/fat, edible oil/fat, food science, etc., can solve the problems of reducing nutritional and health care value, immature technology, affecting oil quality, etc. Achieve the effect of reducing energy consumption, stable operation and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

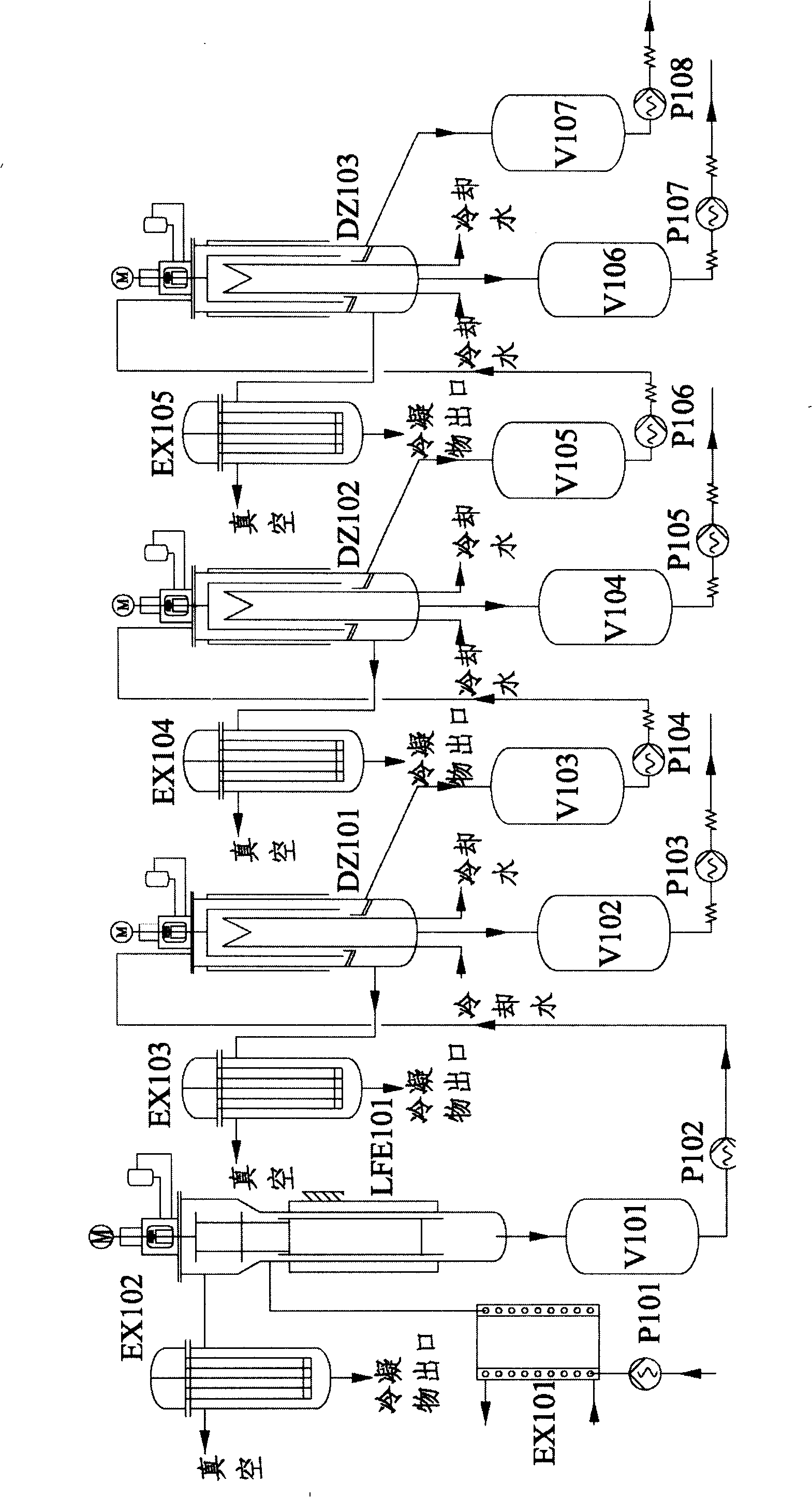

[0035] A three-stage molecular distillation deacidification process for high acid value (35-40mgKOH / g) lard, its main process is described as follows:

[0036] a. The acidified lard that has been finely filtered and washed with saturated NaCl is pumped into the preheater EX101 through the feed pump P101. After preheating to about 100°C, it enters the thin film evaporator LFE101 to remove moisture and light components; evaporation temperature 100°C, operating pressure (absolute pressure) 2000Pa, light components are condensed by EX102.

[0037] b. The acidified lard from which moisture and light components have been removed enters the material temporary storage tank V101.

[0038] c. The acidified lard that has been dehydrated is pumped into the first-stage wiped-film molecular still DZ101 through the first-stage feed pump P102.

[0039] The distillation temperature of the primary molecular still is 170-180°C, the operating pressure (absolute pressure) is 0.5-0.7Pa, the feed r...

Embodiment 2

[0049] A high-acid-value rapeseed oil secondary molecular distillation deacidification process, the main process is described as follows:

[0050] a. The acidified rapeseed oil that has been finely filtered and washed with saturated NaCl is pumped into the preheater EX101 through the feed pump P101. After preheating to about 60C, it enters the thin film evaporator LFE101 to remove moisture and light components; evaporation temperature 100°C, operating pressure (absolute pressure) 2000Pa, light components are condensed by EX102.

[0051] b. The acidified rapeseed oil from which moisture and light components have been removed enters the material temporary storage tank V101.

[0052] c. The acidified rapeseed oil dehydrated is pumped into the first-stage wiped-film molecular still DZ101 through the first-stage feed pump P102.

[0053] The distillation temperature of the primary molecular still is 170-190°C, the operating pressure (absolute pressure) is 0.5-0.7Pa, the feed rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com