Durable clear coatings for aircraft cabin windows

An aircraft and coating technology, applied in the direction of coating, metal material coating process, layered products, etc., can solve problems such as limited durability, and achieve the effect of improving weather resistance and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

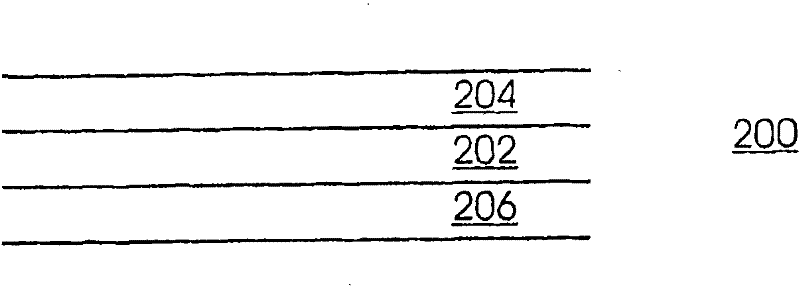

[0023] Such as figure 2 As shown, the two-layer coating 200 of the present invention includes a combination of a first coating 202 and a second coating 204 deposited on a substrate 206 (eg, acrylic substrate 206). In one embodiment, the acrylic substrate 206 may be a common aircraft cabin window 100 .

[0024] In one embodiment, second coating 204 is deposited on acrylic substrate 206 using a plasma-based chemical vapor deposition (CVD) coating process. Plasma CVD coatings are relatively "hard" coatings that offer better wear resistance, chemical inertness, etc. than other coatings produced by wet chemical methods such as sol-gel coatings. The ion bombardment effect that occurs during plasma CVD of silicon-based clear coatings has been shown to improve the hardness and durability of the coatings. Ion bombardment during deposition tends to increase the surface mobility of the deposit and thereby improve the optical quality in terms of haze and clarity of the coating.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com