Method and device for accurately dividing a molten low-viscous glass into small portions

A glass melt, low-viscosity technology, applied in the direction of the feeding machine nozzle, etc., to achieve the effect of avoiding defects, small weight tolerance, and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

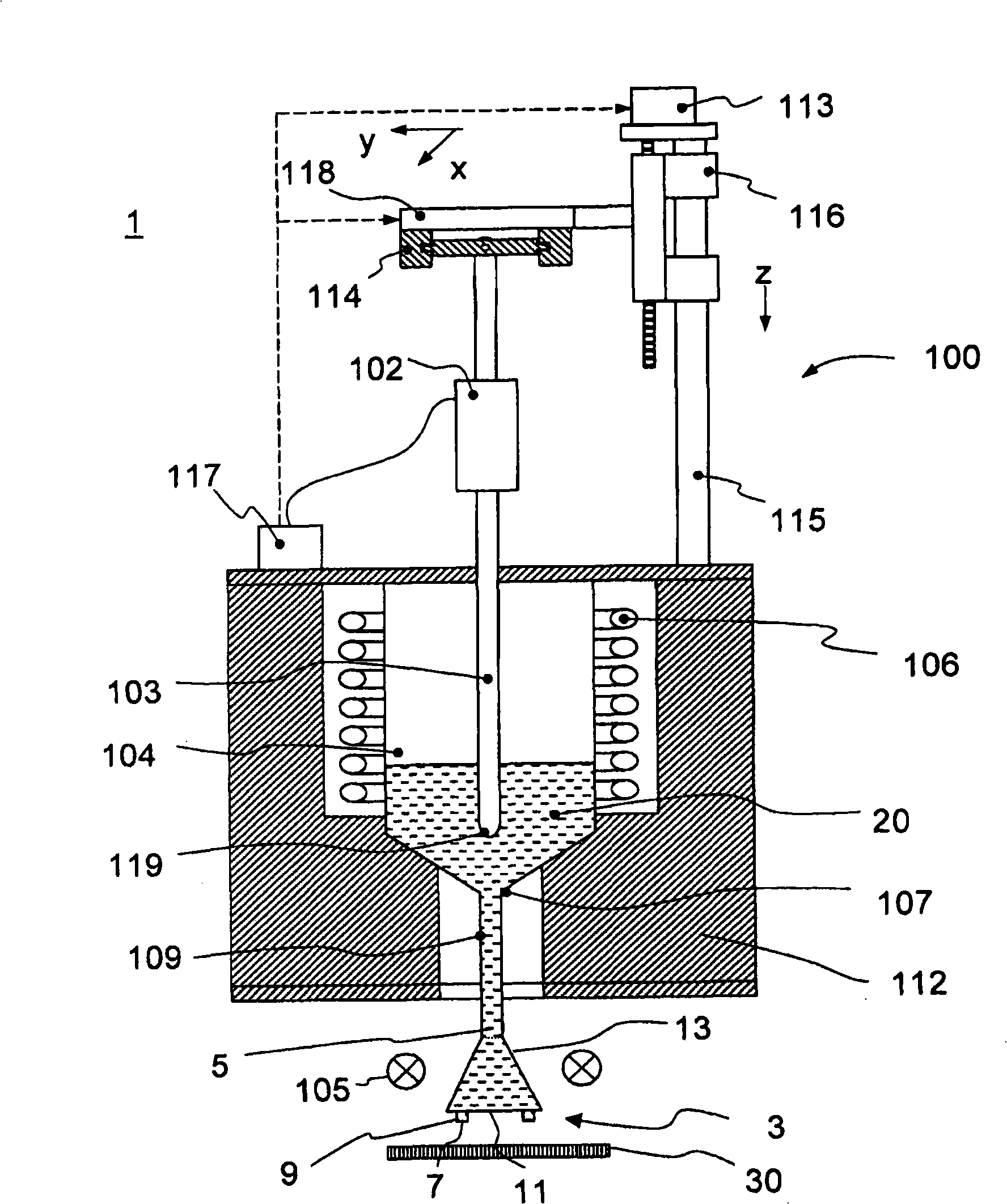

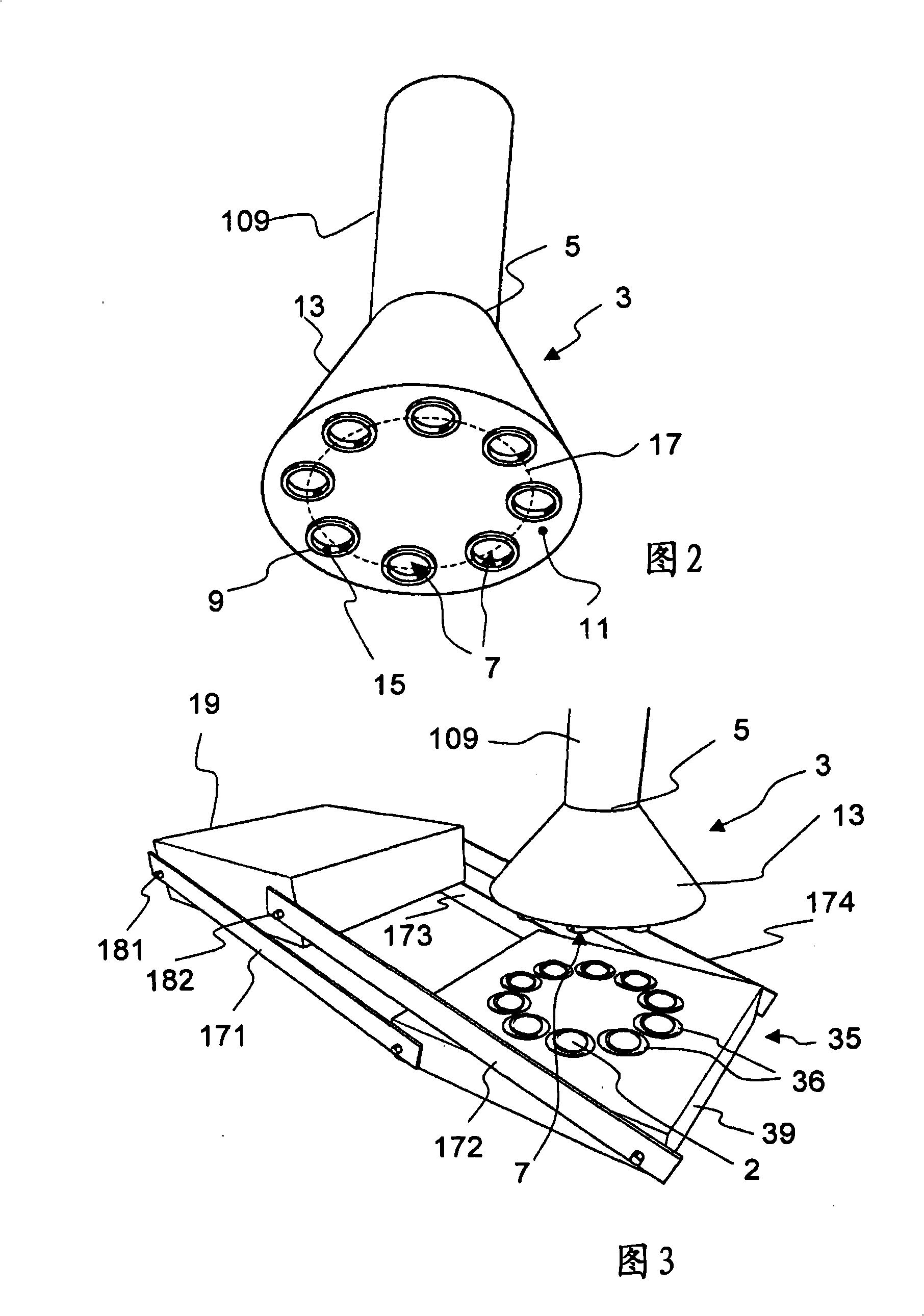

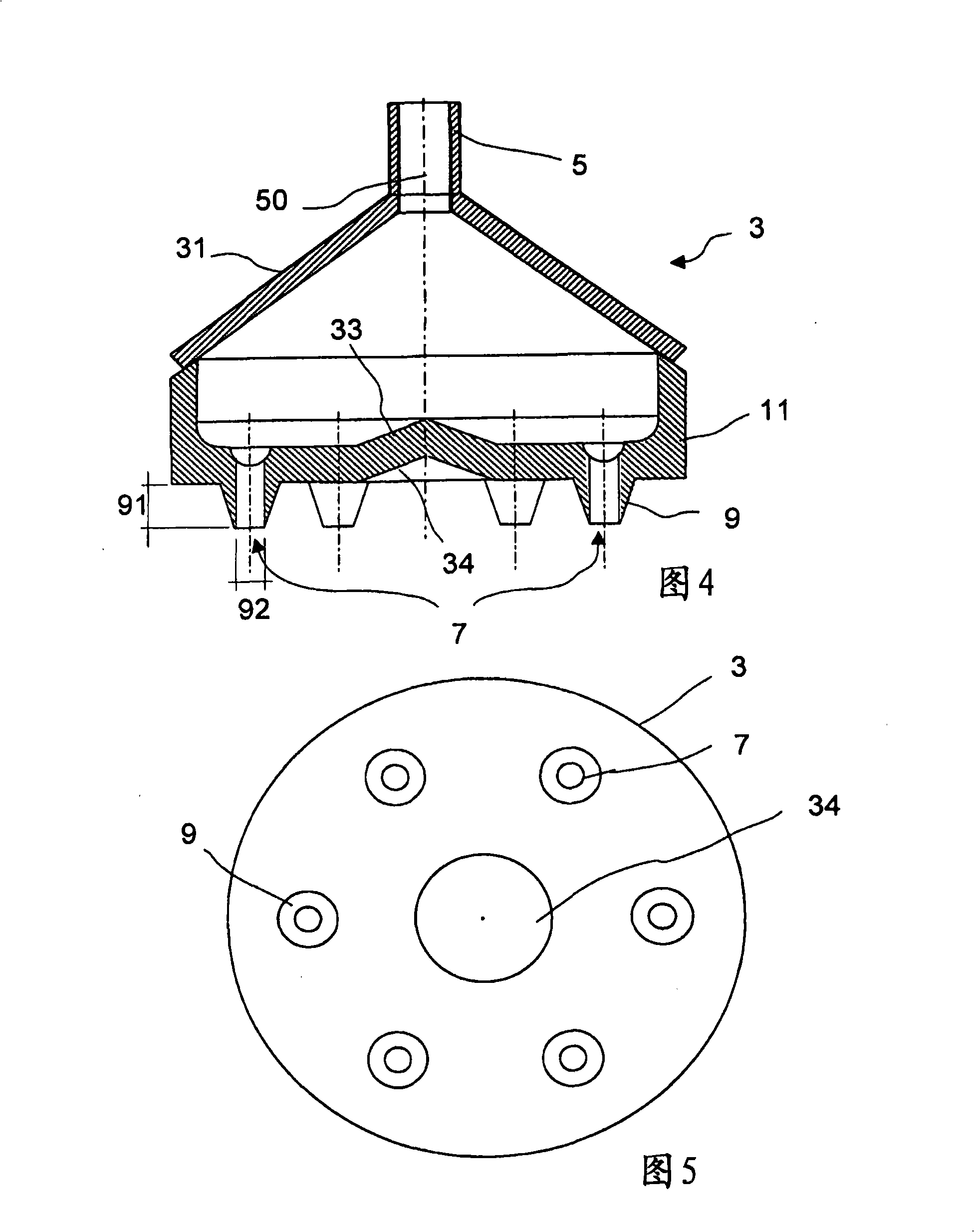

[0063] Refer to the following figure 1 , which shows a first embodiment of a device 1 for simultaneous multiple portioning of glass fractions from a glass melt. The principle of the device is based on a valve arrangement 100 with a valve for interrupting a glass melt flow and a nozzle 3 with a plurality of outlets 7 connected downstream of the valve for neutralizing a glass melt flow.

[0064] exist figure 1 In the example shown, the valve device 100 is designed in particular as a needle feeder with a feed needle 103 . The device is also equipped with a force-measuring device 102 with which, at least during a part of the positioning of the feed needle 103, in particular its tip relative to the valve seat of the feed needle 103, it is possible to measure in particular a direction in x, y and / or z. The force acting on the feed needle 103.

[0065] The device 1 also has a liquid reservoir 104 arranged in a thermal insulation 112 for the low-viscosity glass melt 20 , which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com