Production method of oversize silicon carbide spacing reflection mirror body

A technology with super-large size and manufacturing method, applied in mirrors, installation, optics, etc., can solve problems such as weight increase and image quality degradation, and achieve the effects of reducing weight, reducing deformation errors, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

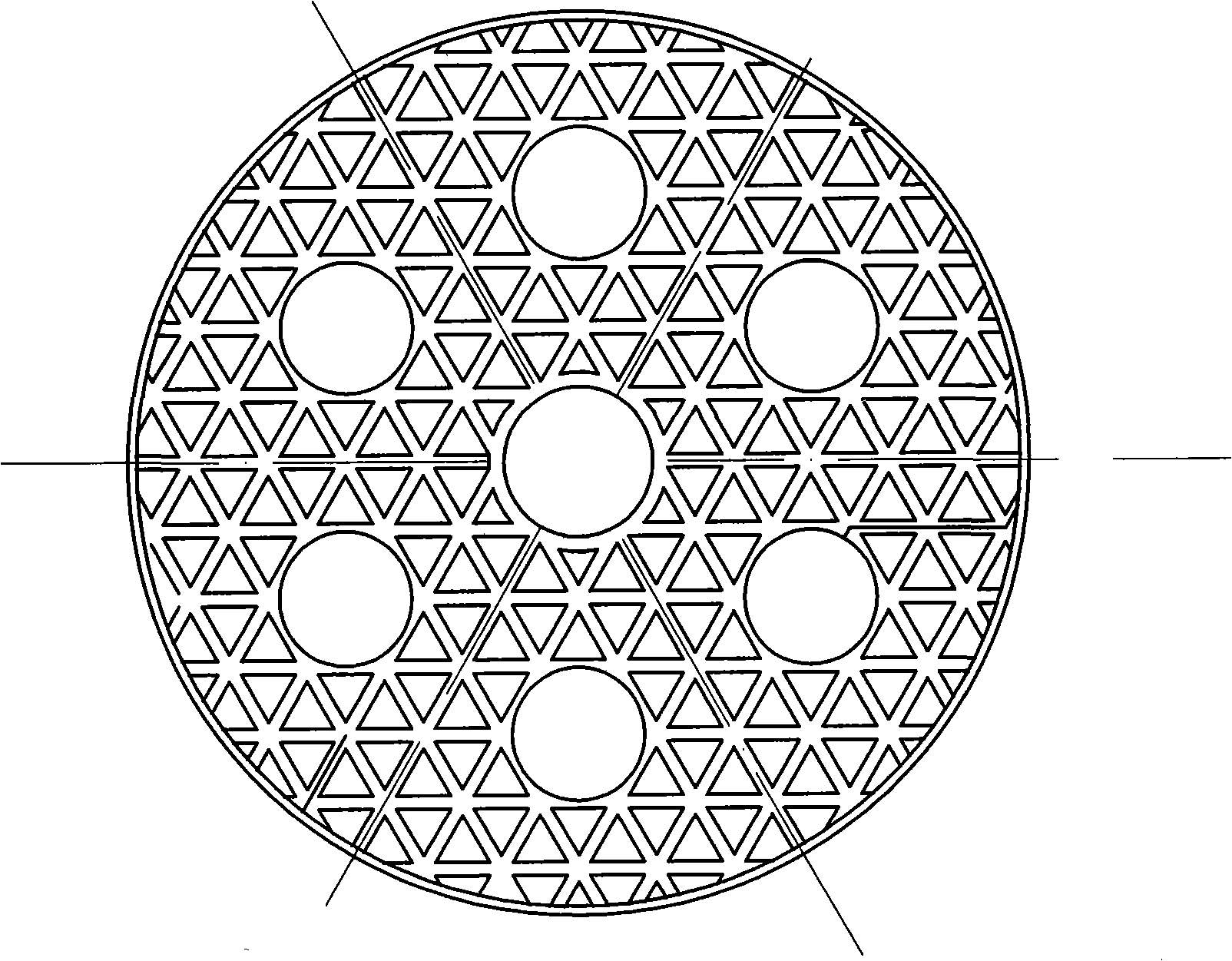

[0026] A method for manufacturing a super-large-sized silicon carbide space mirror body, the composition of which includes: optimizing the shape and size of the mirror, dividing the super-sized mirror into small-sized rough drawings, manufacturing molds and preparing The slurry is poured, and the blank is manufactured by the reaction sintering method, the blank is processed, and the blanks are connected and trimmed by brazing.

Embodiment 2

[0028] The manufacturing method of the ultra-large-sized silicon carbide space mirror body described in Embodiment 1, the division is as follows: according to the determined shape and size of the mirror, the mirror is divided as symmetrically as possible, and the division is planar division , each component contains as many identical shape elements or components as possible.

Embodiment 3

[0030] In the manufacturing method of the ultra-large-sized silicon carbide space mirror body described in Example 1, in the mold manufacturing process, high-quality gypsum powder and water are mixed evenly in a ratio of 3:2 to cast the mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com