Jetting flow blower fan

A technology of air cooler and cold air duct, which is applied in water shower coolers, space heating and ventilation, heating methods, etc., and can solve problems such as complex structure, large wind resistance, and difficulty in defogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

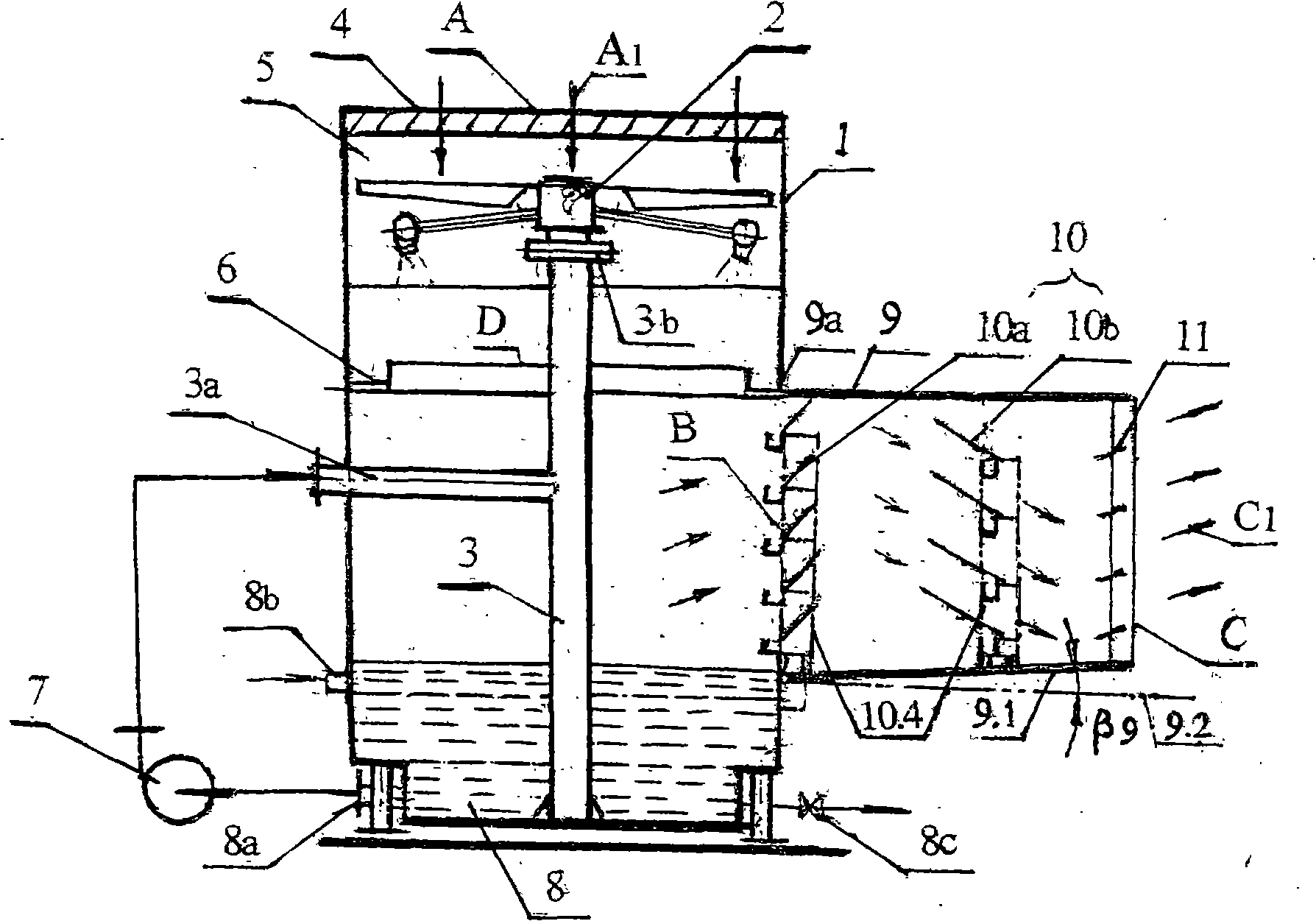

[0017] Example 1: see figure 1 , figure 2 , Figure 5, Figure 6.

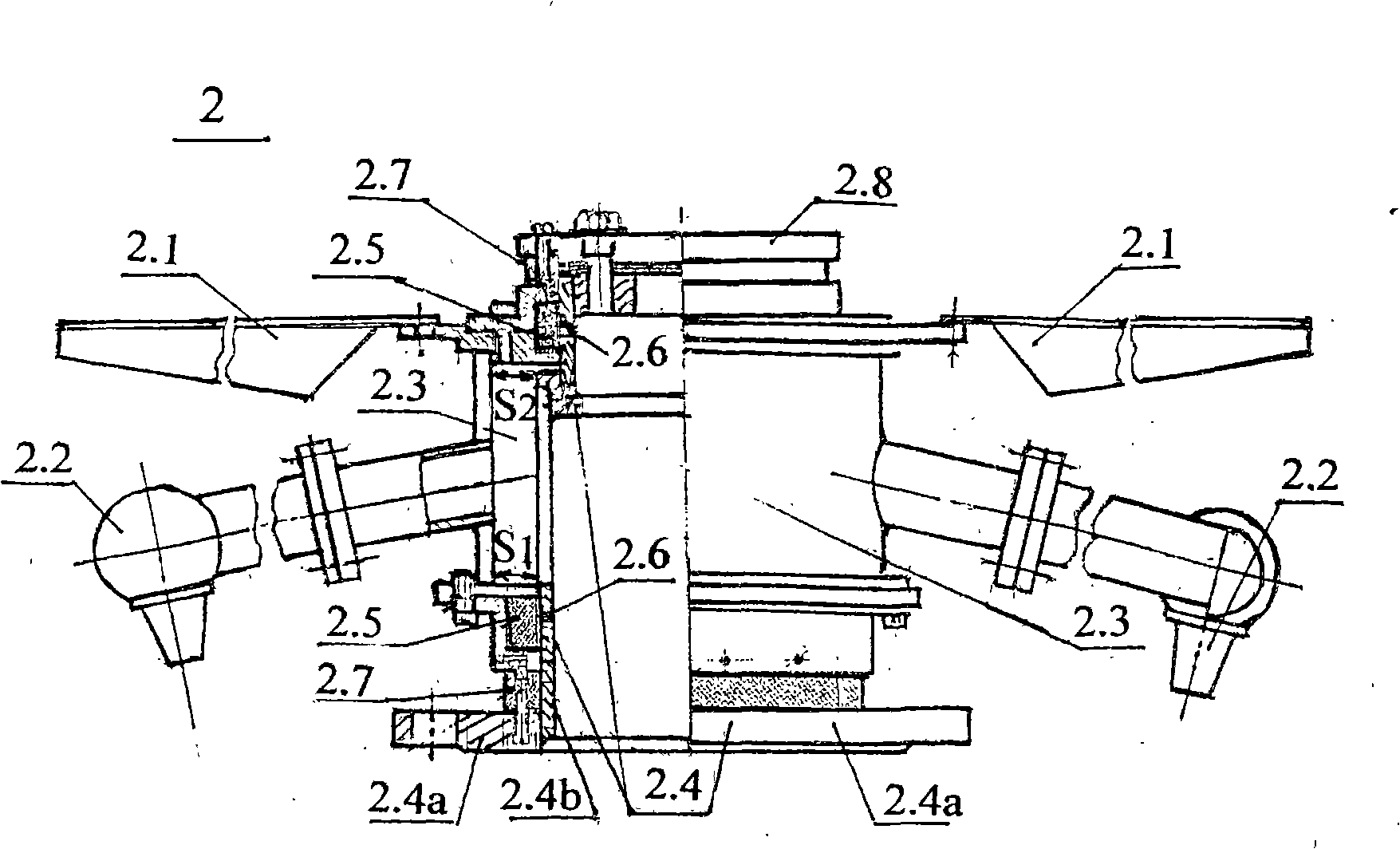

[0018] See figure 1 , in the body 1 of the jet air cooler, a demister 4 is set at the top hot air inlet A, and the cold air outlet B is set above the bottom water tank 8, where the body wall is sealed on three sides, leaving an opening, and the body side wall is extended to become The cold air passage 9, and the side wall opening 9a is sealed. There is an inclination angle β9 between the bottom surface 9.1 of the cold air duct 9 and the vertical direction 9.2 of the side wall of the water tank, that is, a backwater slope is provided between the bottom surface 9.1 and the horizon line 9.2. Two layers of water-absorbing type deflector demisters 10 are arranged in the cold air channel 9 . The tail end of the cold air passage is a cold air outlet C, and a movable air regulating plate 11 is established at C. Below the 'spray device 2', above the cold air duct 9, the center is an annular water spraying sieve pl...

Embodiment 2

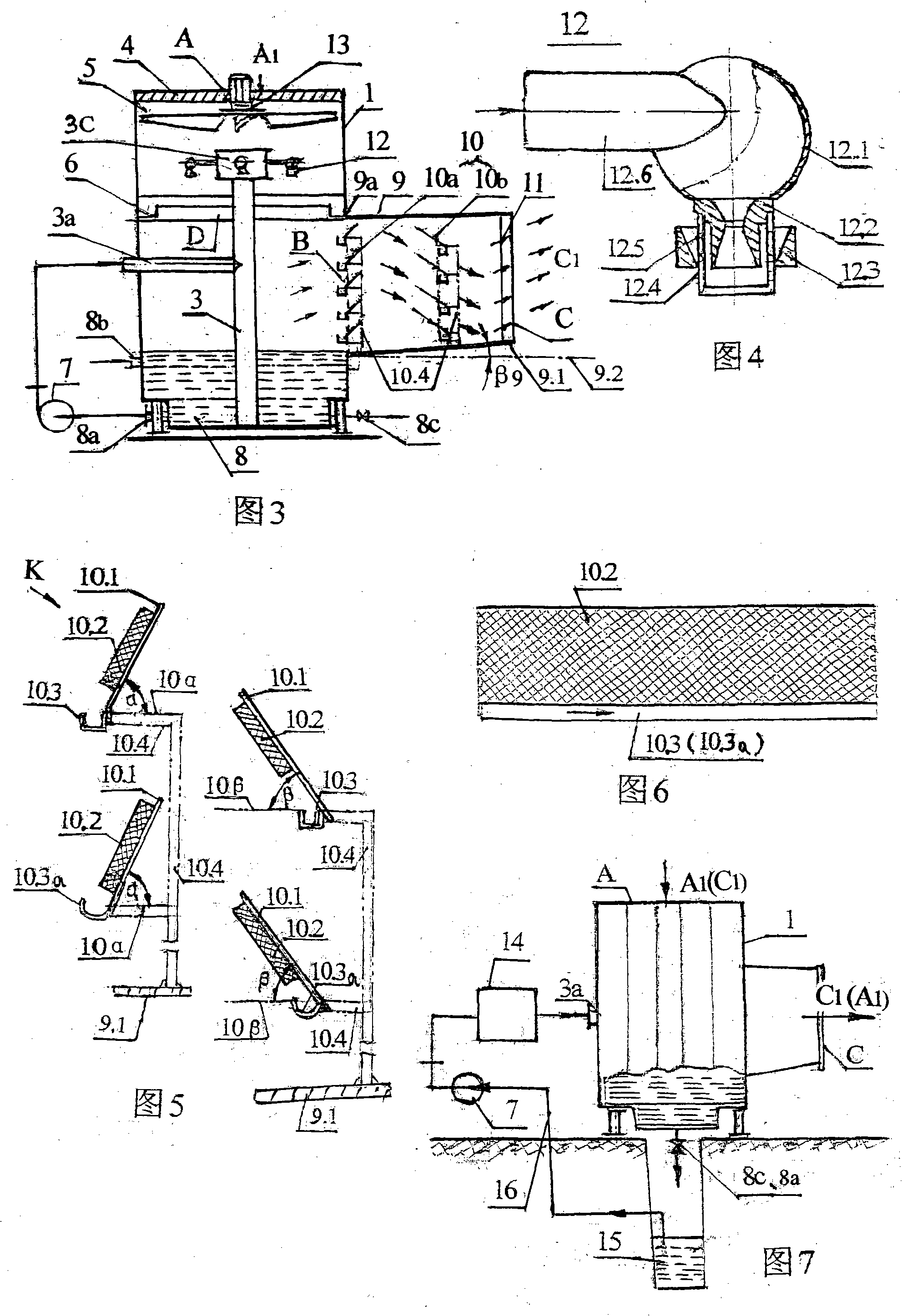

[0023] Embodiment 2: see Fig. 3, Fig. 4, mechanical ventilation jet air cooler

[0024]Compared with Example 1 except for the following structural differences, the rest are the same: see Fig. 3, the embodiment 1 'spray device 2' is replaced by the following components: 1. install a downward drafting electric fan 13 at the top air inlet A; Below 13, the cylindrical water distribution chamber 3c is adorned at the top of the water supply pipe 3; four swirl atomizing nozzles 12 (at least two) are adorned in the water distribution chamber circumferential direction. The working process is similar to that of Example 1, but the working water pressure of the swirling atomizing nozzle 12 needs to be greater than 0.12Mpa, and the power consumption of the fan 13 is added, so the energy consumption increases. But production costs have come down.

[0025] As shown in Fig. 4, the swirling atomizing nozzle 12 adopts the same lower spraying nozzle 2.2 as that in the 'spray device 2', that is,...

Embodiment 3

[0026] Embodiment 3: see Fig. 7, geothermal jet air conditioner.

[0027] Compared with Embodiment 1 except the following structural differences, the rest are the same: see Fig. 7, i. outside the body 1, a solar heater 14 is added between the water pump 7 and the water inlet pipe 3a; ii. the water inlet of the water pump 7 passes through the pipeline 16 and groundwater The well 15 is connected; iii. the water outlet pipe 8a and the drain valve 8c are arranged at the bottom of the water tank 8, and cold water or hot water is discharged into the groundwater well 15; iv. the replenishment pipe 8b installed on the side wall of the water tank 8 is canceled. In this way, a water supply and drainage circulation system is formed. Top air inlet A can take in hot air A in summer 1 Or into the cold wind in winter C 1 , the corresponding air outlet C will emit dry cold air C 1 or dry hot air A 1 .

[0028] The two-phase heat and mass transfer of air and water has the following charac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com