Fluid state energy-saving heater

A heater and fluid state technology, applied in the field of fluid state energy-saving heaters, can solve problems such as unsafe, bursting, energy waste, etc., and achieve the effects of improving high-temperature heat radiation defects, improving energy utilization efficiency, and uniform indoor temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

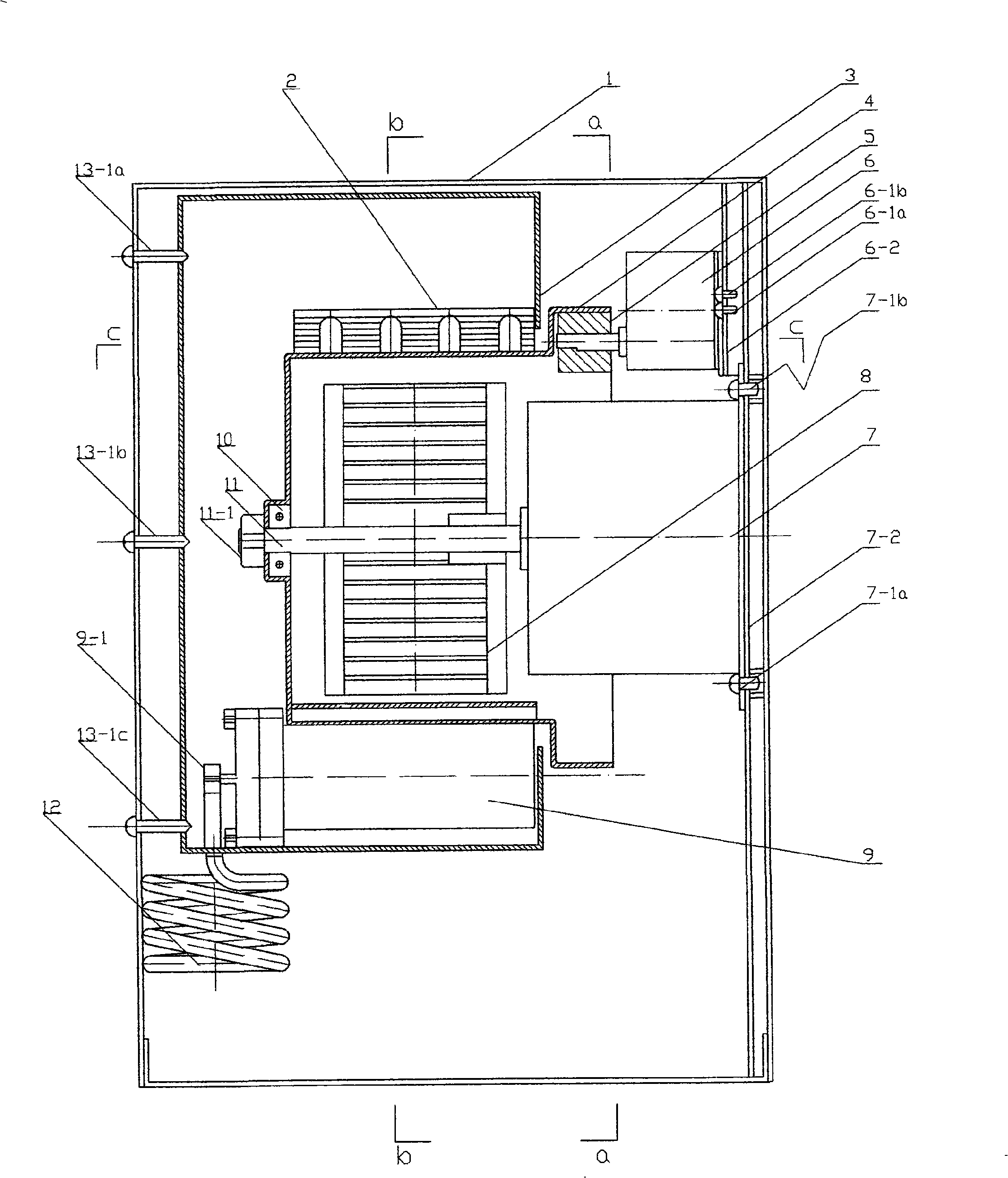

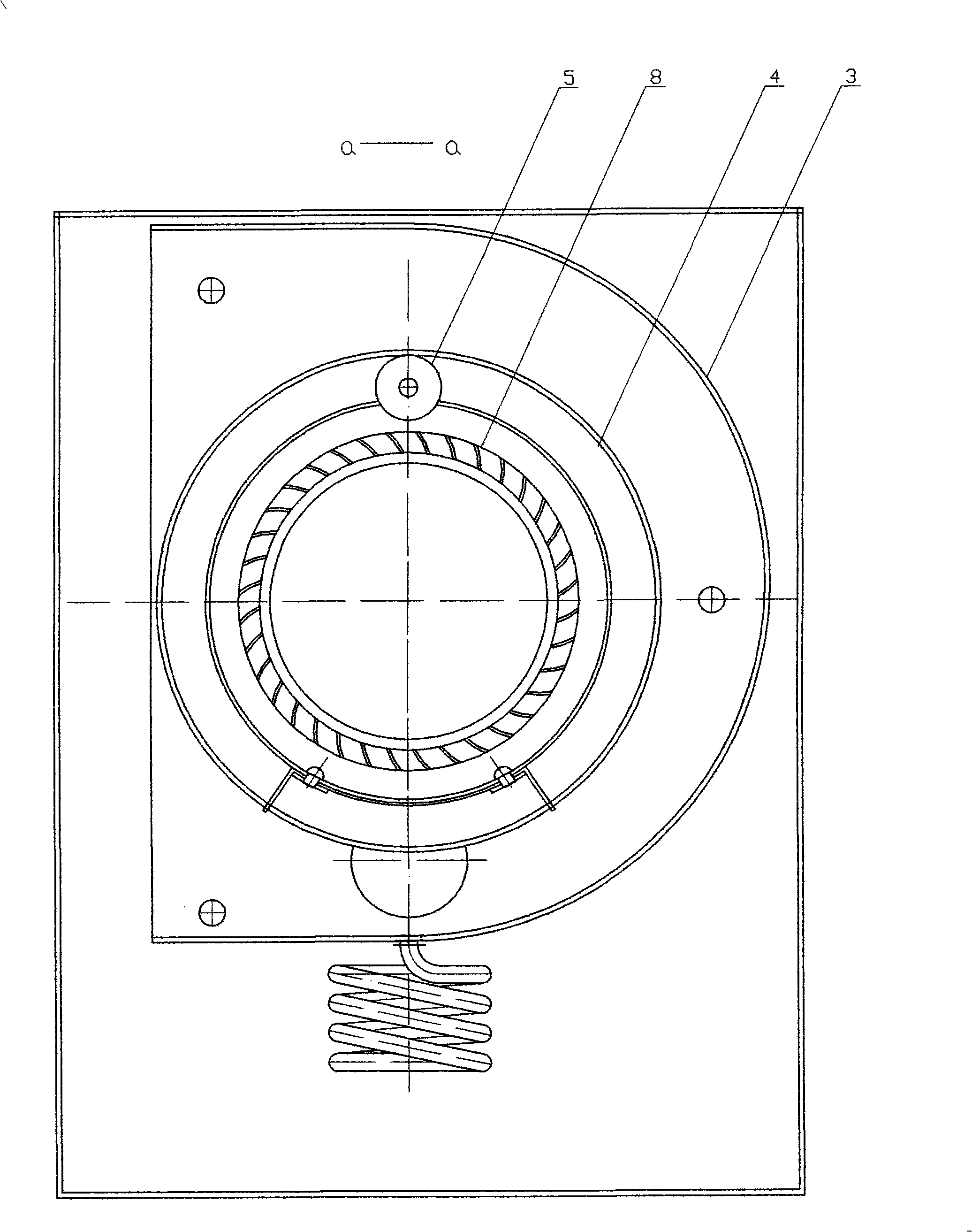

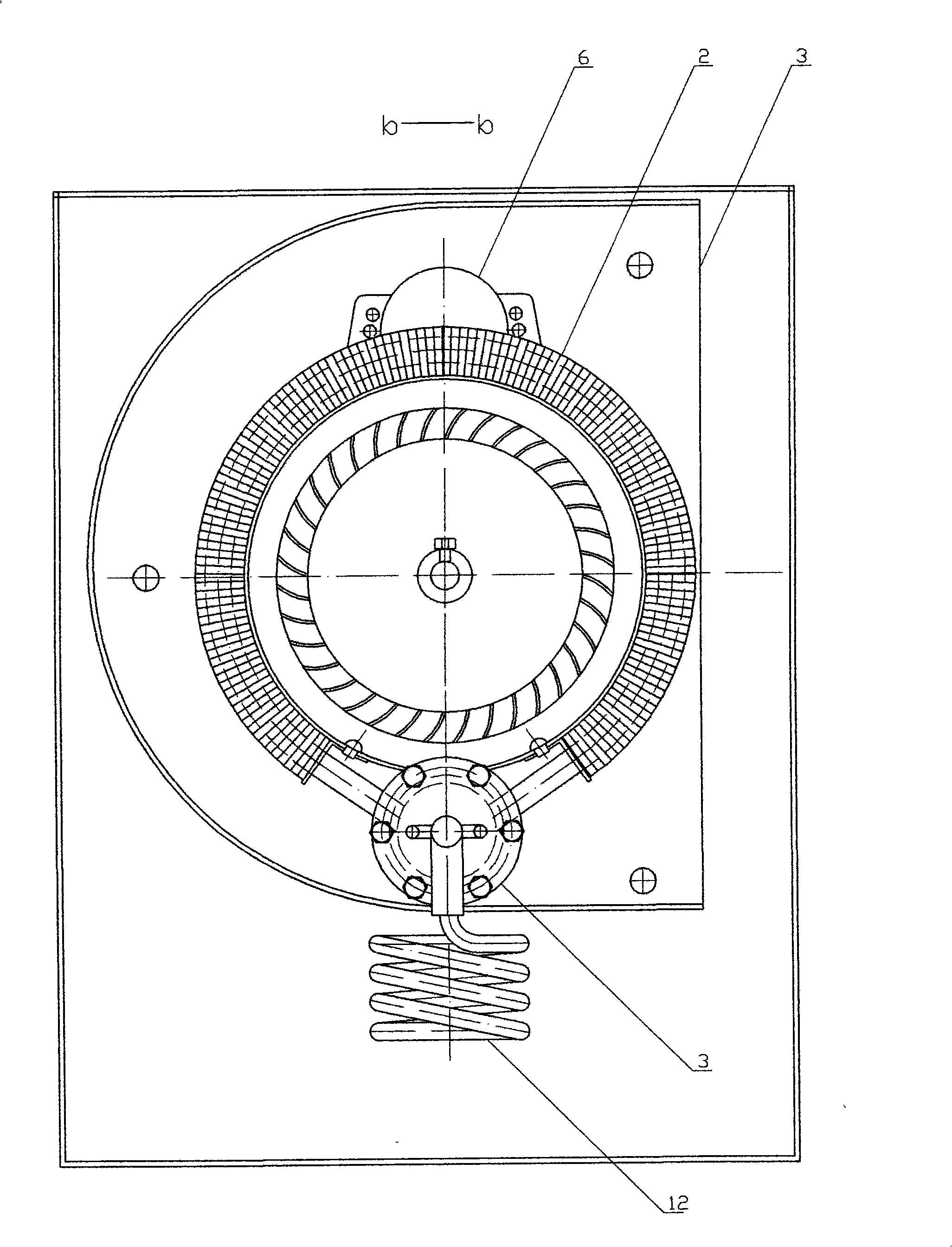

[0015] Refer to attached Figure 6 , attached Figure 7 , the oil flow pipe 2-2 of the annular radiator 2 communicates with the oil tank 9-3 of the oil heating electric heater 9, and the flowing oil heated by the electric heating pipe 9-4 in the oil heating electric heater 9 is in the oil of the annular radiator 2 The flow pipe 2-2 flows, and a centrifugal wind wheel 8 is installed in the annular radiator 2 ring. When the centrifugal wind wheel 8 is driven by the fan motor 7, the airflow blown by the centrifugal wind wheel 8 passes through the annular radiator 2, and the oil flow pipe 2 The heat of the heated flowing heat transfer oil in the -2 dissipates heat on the surface of the oil flow pipe 2-2 and the heat sink 2-1 connected in series with the oil flow pipe 2-2 along with the air flow. Refer to attached figure 1 , the annular radiator 2 is set on the turret 4 of the outer ring of the bearing 10 on the fan motor shaft 11, one end is axially limited by the shaft end nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com