Protective equipment for melt-out magnesium/magnesium alloy

A protection device and magnesium alloy technology are applied in the field of protection devices for molten magnesium/magnesium alloys, which can solve problems such as cost increase, achieve simple assembly, reduce production costs, and achieve easy effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

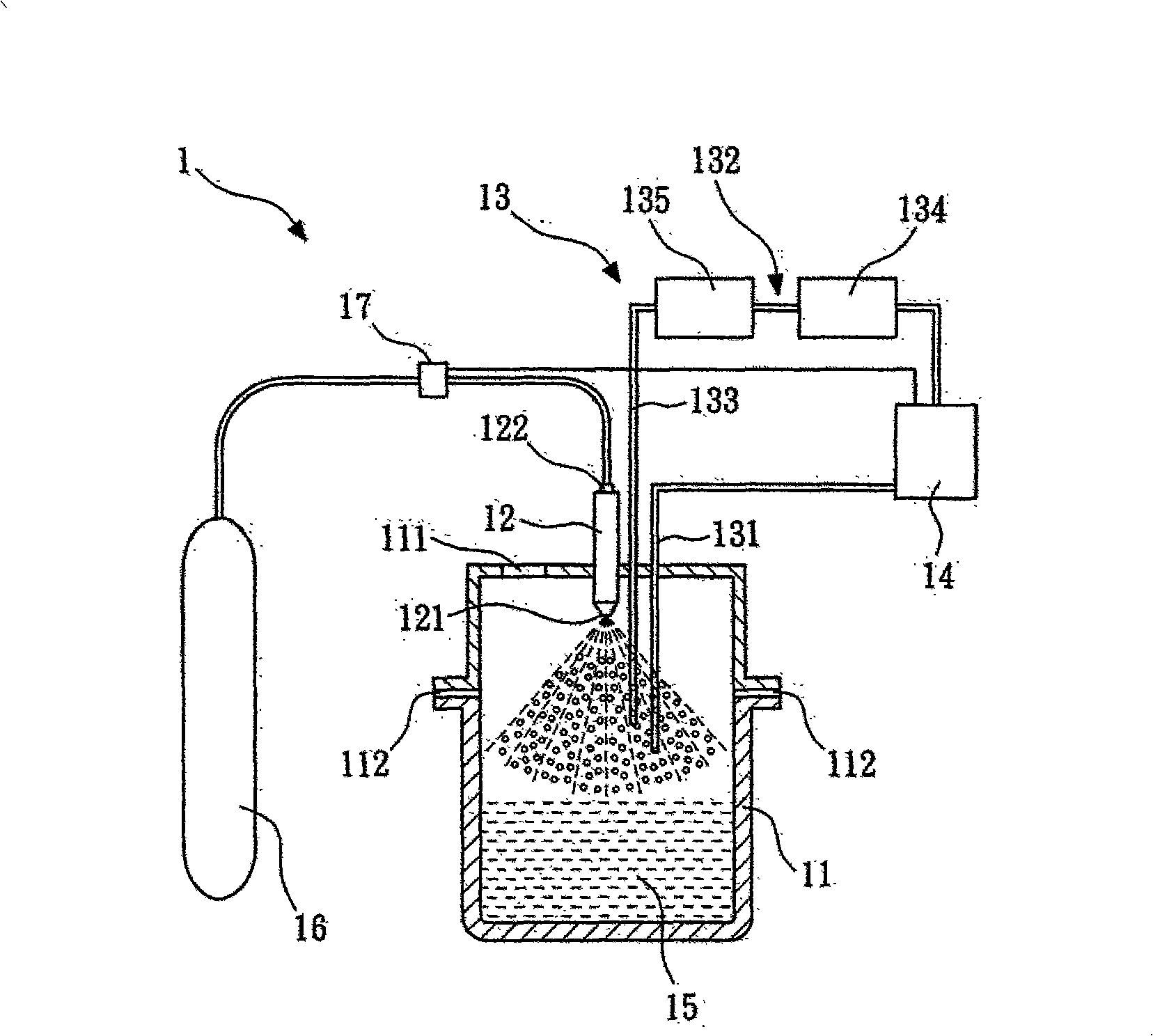

[0009] refer to figure 1 , which shows a schematic diagram of the protective device for molten magnesium / magnesium alloy of the present invention. The protection device 1 includes: a furnace 11 , a nozzle module 12 , a sampling system 13 and a data processing device 14 . The melting furnace 11 is used to melt and contain molten magnesium / magnesium alloy 15 . The top of the furnace 11 has an observation window 111 and at least one gas channel 112 . The state inside the furnace 11 can be directly observed through the observation window 111 . The gas channel 112 is used to exhaust the air originally in the furnace 11 to reduce the oxygen content in the furnace 11 , thereby reducing the chance of the molten magnesium / magnesium alloy 15 contacting oxygen.

[0010] The nozzle module 12 has a first end 121 and a second end 122, the first end 121 and the second end 122 are connected, the first end 121 is arranged inside the melting furnace 11, and the second Terminal 122 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com