Die device and method for manufacturing laminate

A manufacturing method and mold technology, which is applied in manufacturing tools, manufacturing stator/rotor bodies, metal processing equipment, etc., can solve problems such as punching die damage, and achieve the effect of preventing burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

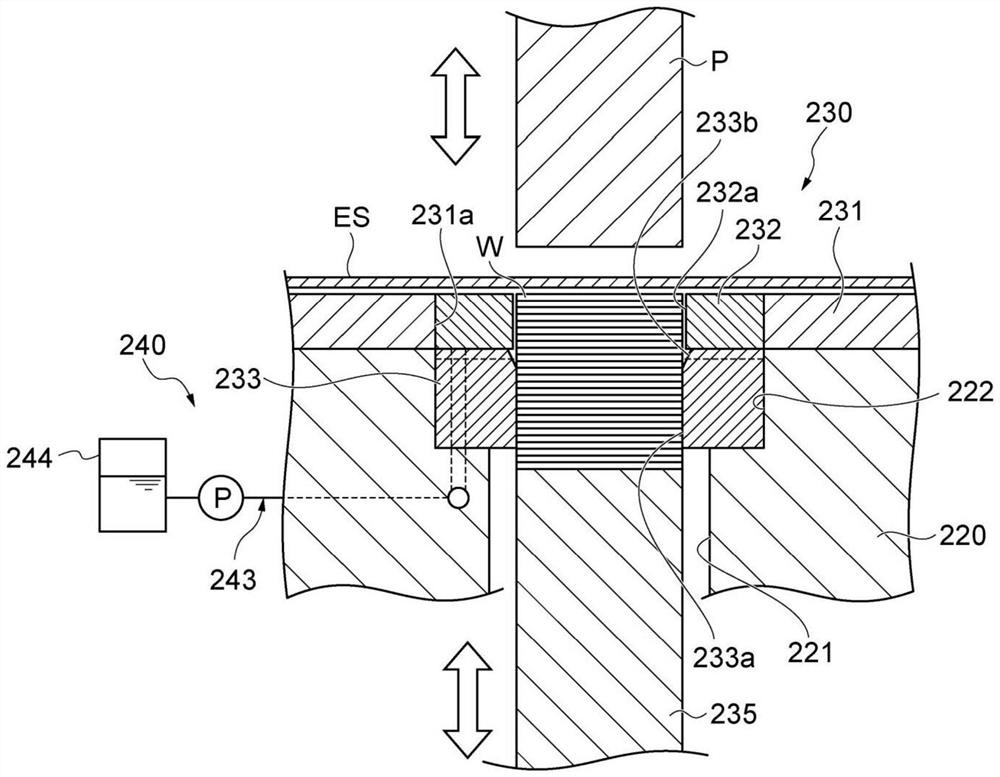

[0031] Hereinafter, embodiments according to the present invention will be described in detail with reference to the drawings. In the description of the drawings, the same reference numerals are assigned to the same elements, and overlapping descriptions are omitted.

[0032] [Stator laminated core]

[0033] First, refer to figure 1 , the structure of the stator laminated core 1 will be described. The stator laminated core 1 (stator) has a cylindrical shape. A through-hole 1 a extending along a central axis Ax is provided in a central portion of the stator laminated core 1 . A rotor core (rotor) not shown can be arranged in the through hole 1a. The stator laminated core 1 constitutes a motor together with the rotor laminated core. The stator laminated core 1 has an annular yoke 2 and teeth 3 .

[0034] The yoke 2 has an annular shape and extends to surround the central axis Ax. The inner diameter, outer diameter, and width of the yoke 2 can be set to various sizes accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com