Edible butter composition and method for preparing butter powder with the same as raw material

A technology of composition and butter powder, applied in the direction of butter extraction, application, dairy products, etc., can solve the problems of low fat content and oil leakage, reduce emulsification time, improve dispersibility and stability, and shorten production effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

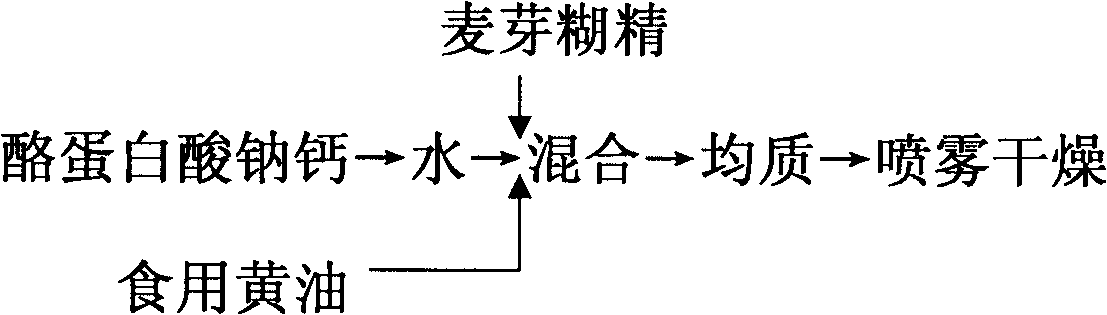

Method used

Image

Examples

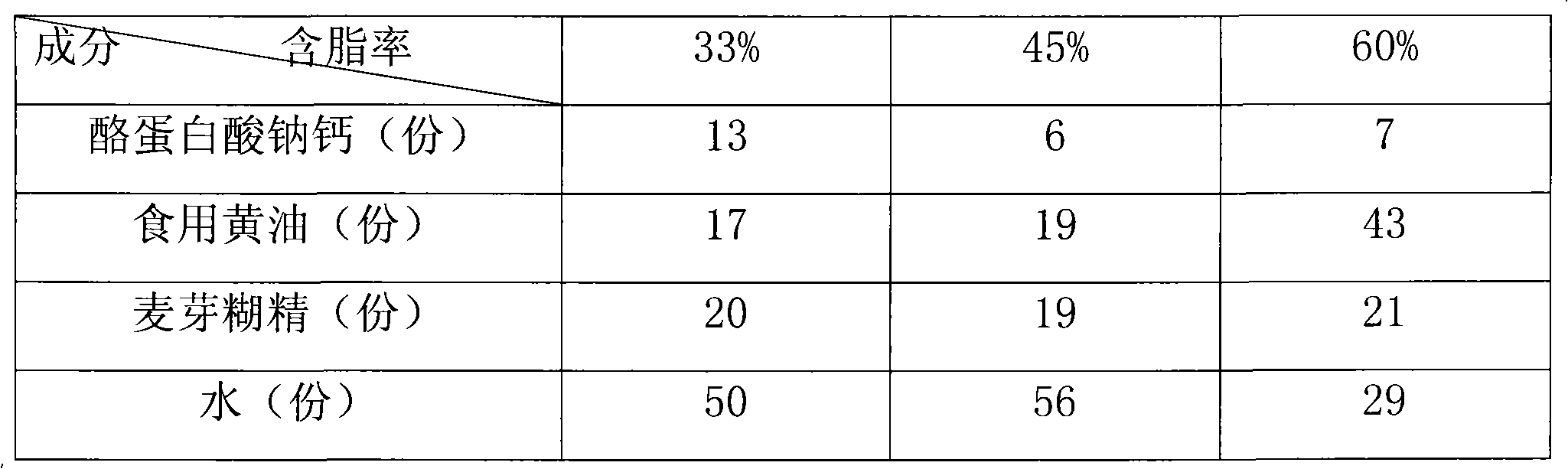

Embodiment 1

[0070] Example 1 Put casein and water into a conversion tank at a ratio of 1:3, stir evenly, and heat up to 40-45°C; slowly stir and add 20% NaOH solution to make the pH of the feed liquid reach 5.4, and heat up to 60°C ℃, and the heating process is completed within 30min; then add Ca(OH) 2 Suspension liquid, make the pH value of the feed liquid reach 6.6, and raise the temperature to 72°C, stir for 30 minutes and then enter the next process; 15s; the feed liquid passes through the high-pressure homogenizer with a pressure of 18MPa; spray drying: the inlet air temperature is 160°C, the exhaust air temperature is 80°C, the temperature inside the drying tower is 72°C, the pressure is 18MPa, the feed liquid temperature is 80°C, and the feed liquid flow rate is 700L / h; add 32kg of water to the high-shear emulsification tank, then add 6kg of sodium calcium caseinate, after the sodium calcium caseinate is completely dissolved, then add 19kg of maltodextrin, 1600~1800rpm / min; After ...

Embodiment 2

[0071] Example 2 Put casein and water into the conversion tank at a ratio of 1:5, stir evenly, and heat up to 42°C; slowly stir and add 23% NaOH solution to make the pH of the feed liquid reach 5.6, and heat up to 62°C, And the heating process is completed within 30min; then add Ca(OH) 2 Suspension liquid, make the pH value of the feed liquid reach 6.7, and raise the temperature to 74°C, stir for 35 minutes and then enter the next process; 18s; the feed liquid passes through the high-pressure homogenizer with a pressure of 20MPa; spray drying: the inlet air temperature is 180°C, the exhaust air temperature is 83°C, the temperature inside the tower is 76°C, the pressure is 20MPa, the feed liquid temperature is 83°C, and the feed liquid flow rate is 730L / h; add 42 kg of water to the high-shear emulsification tank, then add 8 kg of sodium calcium caseinate, after the sodium calcium caseinate is completely dissolved, then add 20 kg of maltodextrin, 1700rpm / min; After mixing even...

Embodiment 3

[0072] Example 3 Water in the ratio of 1:4 of casein and water was put into the conversion tank, stirred evenly, and the temperature was raised to 45°C; slowly stirred and 25% NaOH solution was added to make the pH value of the feed liquid reach 5.8, and the temperature was raised to 65°C. ℃, and the heating process is completed within 30min; then add Ca(OH) 2 Suspension liquid, make the pH value of the feed liquid reach 6.8, and raise the temperature to 75°C, stir for 40 minutes and then enter the next process; after the conversion is completed, the feed liquid is rubber milled by a rubber mill, and the temperature of the feed liquid is raised to 90°C, and kept for 20s The feed liquid passes through the high-pressure homogenizer with a pressure of 25MPa; spray drying: the inlet air temperature is 200°C, the exhaust air temperature is 85°C, the temperature inside the tower is 78°C, the pressure is 25MPa, the feed liquid temperature is 85°C, and the feed liquid flow rate is 750L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com