Sheet adhering apparatus and sheet adhering method

A sheet sticking device and sheet technology, which are applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of unnecessary consumption of sheets, inability to use wafer sticking areas in recessed areas, uneven thickness, etc., and achieve the effect of eliminating unnecessary consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

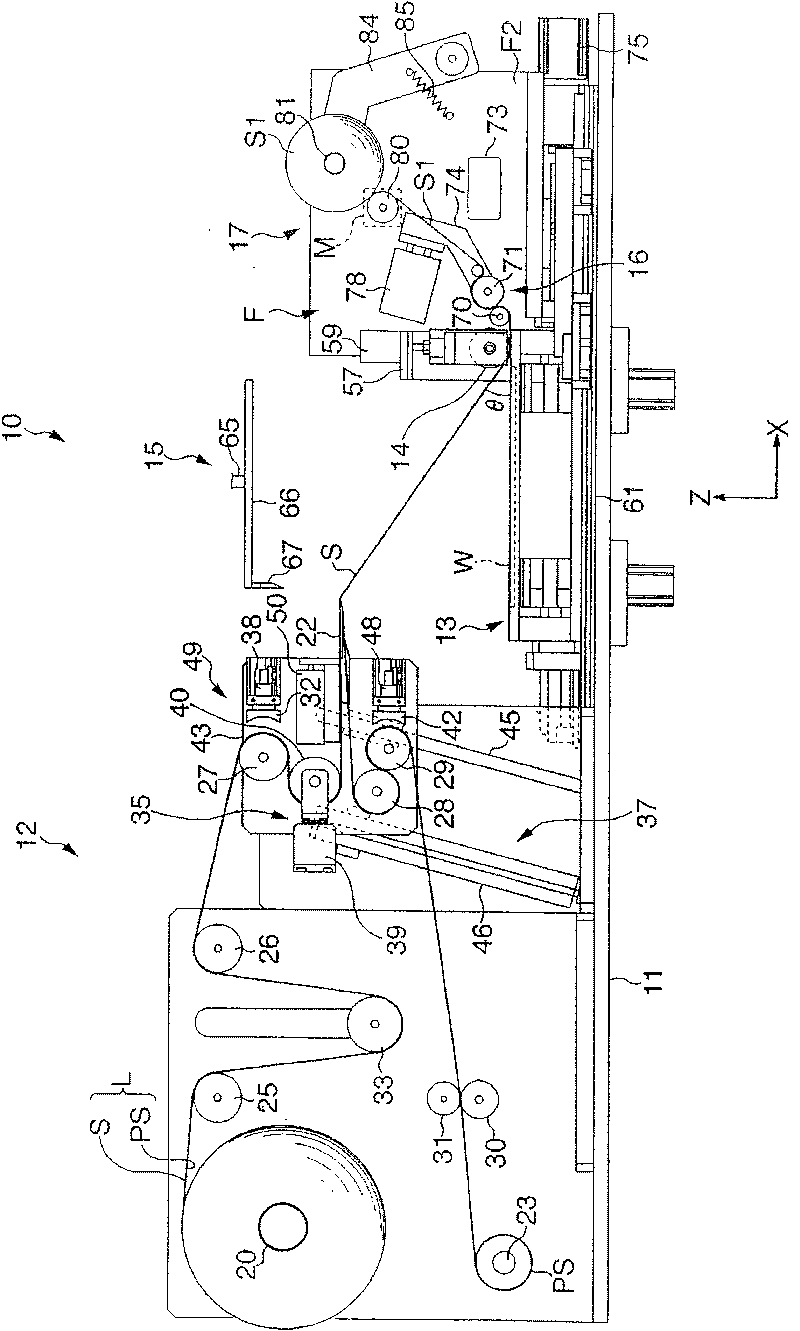

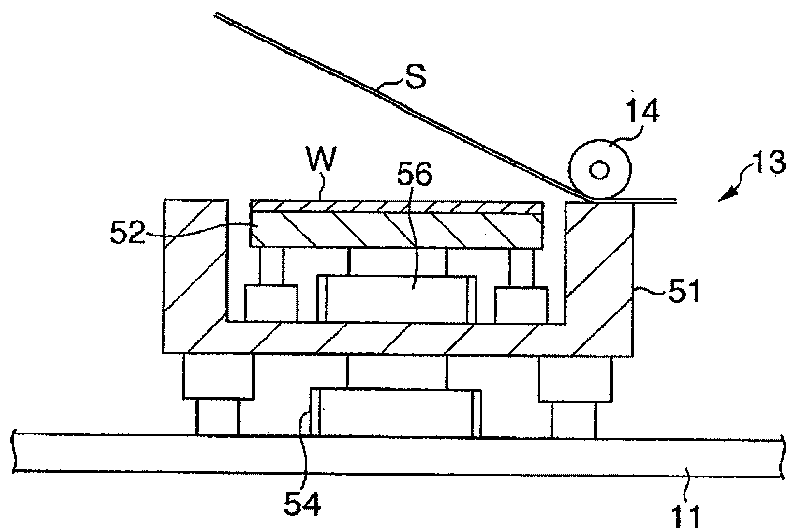

[0032] figure 1 A schematic front view showing the sheet sticking device according to this embodiment, figure 2 A schematic perspective view thereof is shown. In these figures, the sheet sticking device 10 is configured with the following parts: a sheet lead-out unit 12 arranged on the upper portion of the base 11; a table 13 supporting the wafer W as a plate-shaped member; The tab S imparts pressing force, and sticks the sticky sheet S to the squeeze roller 14 of the wafer W; Cutter 15; peeling device 16 for peeling unnecessary adhesive sheet S1 outside wafer W from the upper surface of table 13; and winding device 17 for winding unnecessary adhesive sheet S1.

[0033] The above-mentioned sheet lead-out unit 12 is constituted by comprising the following parts: a support roller 20 supporting a roll-shaped roll paper L, and a belt-shaped adhesive sheet S is temporari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com