Core strapping machine with tension controller

A technology of tension controller and strapping machine, which is applied to the parts of strapping machinery and strapping materials, etc., which can solve the problems that the core cannot be bundled and affects the product process, etc., and achieve the effect of expanding the tension and ensuring the tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

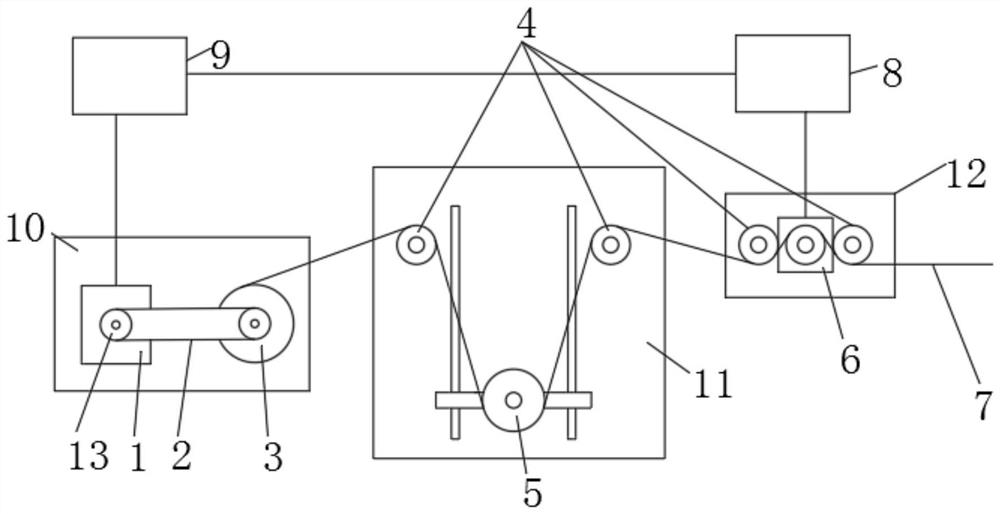

[0024] refer to figure 1 A kind of core binding machine with a tension controller shown includes a fixed bracket 10, a mounting bracket 11 and a connecting bracket 12 arranged in sequence, and the fixing bracket 10, the mounting bracket 11 and the connecting bracket 12 can be any of the prior art One, the side of the fixed bracket 10 is equipped with a material cutting mechanism 3 and a servo motor 1, the material cutting mechanism 3 and the servo motor 1 can be any one in the prior art, the side of the material cutting mechanism 3 and the servo motor 1 All are equipped with synchronous wheel 13, two synchronous wheels 13 are connected by synchronous belt 2, synchronous wheel 13, synchronous belt 2 can be any one in the prior art, and the side portion of mounting bracket 11 is equipped with buffer wheel 5, and connecting bracket The side portion of 12 is equipped with tension sensor 6, and both sides of tension sensor 6 and buffer wheel 5 are all provided with guide wheel 4, a...

Embodiment 2

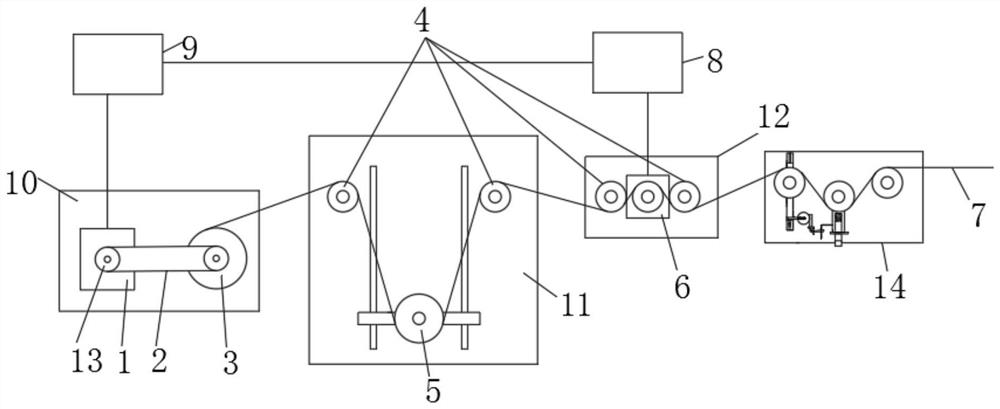

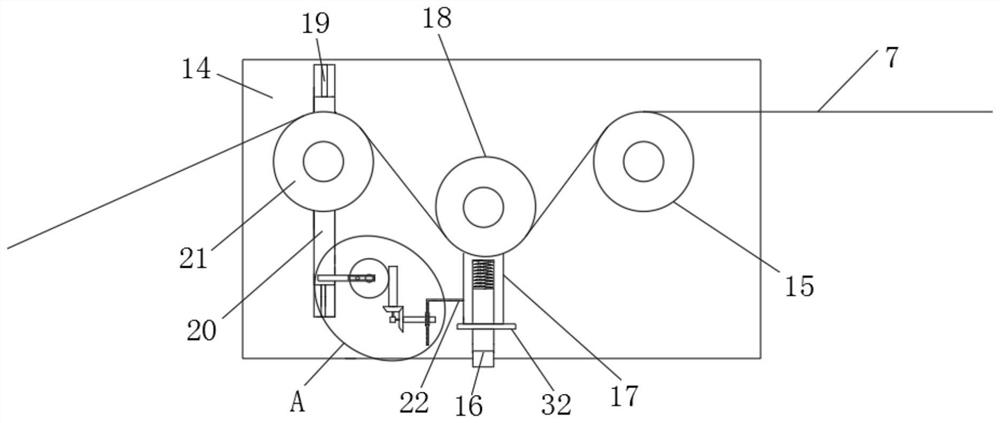

[0028] On the basis of embodiment 1, with reference to Figure 2-4As shown, one side of the connecting bracket 12 is provided with an adjusting bracket 14, and the adjusting bracket 14 can be any one in the prior art. It can be installed on the L-shaped rectangular column 16 on the side of the adjustment bracket 14 by means of welding in the prior art. The L-shaped rectangular column 16 is slidably sleeved with a rectangular block 17. The top of the L-shaped rectangular column 16 can be passed through the existing technology. The mode of welding is equipped with spring, fixed wheel 15, L-shaped rectangular column 16, rectangular block 17, spring can be any one in the prior art, and spring is in stretched state, and the deformation amount that its stretching produces is with binding iron wire 7 The tension is the same, the top of the spring is connected with the rectangular block 17, the side of the rectangular block 17 is rotated with a tension moving wheel 18, the tension mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com