Textile machine, in particular spinning mill preparation machine with a drafting equipment

A technology of textile machinery and drafting device, which is applied in the field of textile preparation machinery, can solve the problems of speed transmission error, high noise, and inability to realize stepless speed regulation, and achieve the effects of high precision, large contact area, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

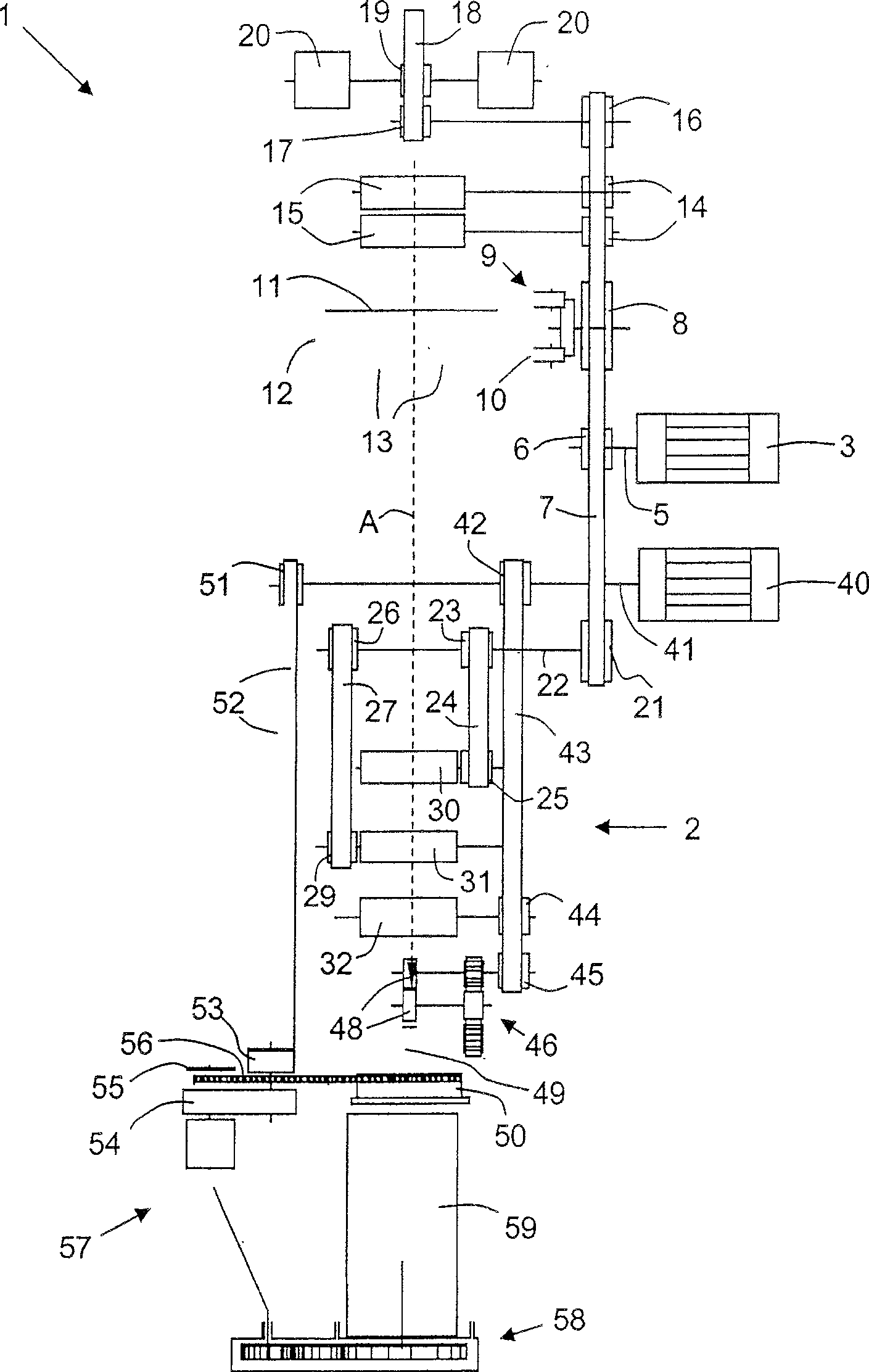

[0034] figure 1It is a transmission arrangement diagram of a drawing frame (Strecke) 1 with a drafting device 2 . Each element of the drawing frame 1 is driven by two motors 3, 40, the first motor 3 is used to drive the elements of the head of the drafting device 2 and the two front drafting rollers, while the second motor 40 is used to drive the rear drafting Elements at the rear of the roller and drafting unit. In order to realize the power transmission between the drive / drive shafts according to the invention, a conveyor belt with at least two longitudinal ribs on a running surface is used.

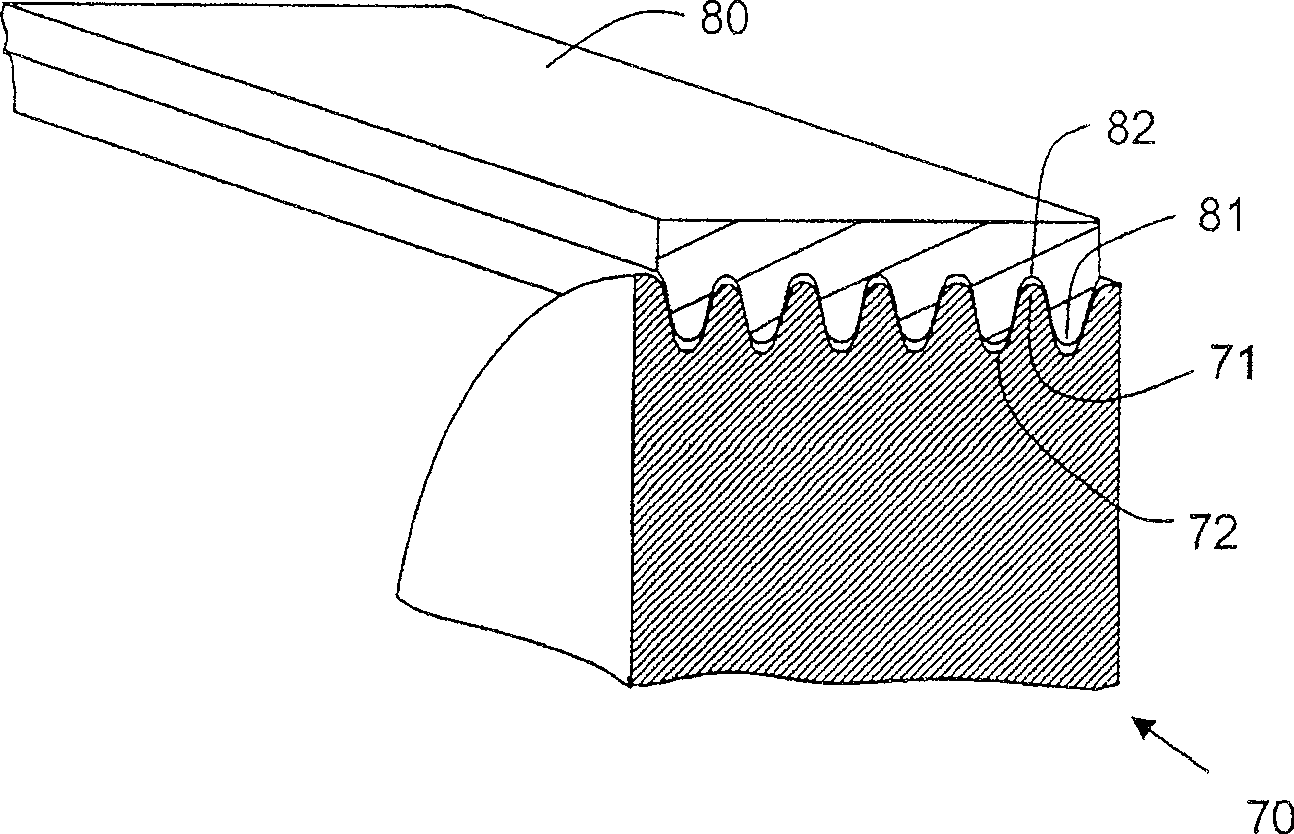

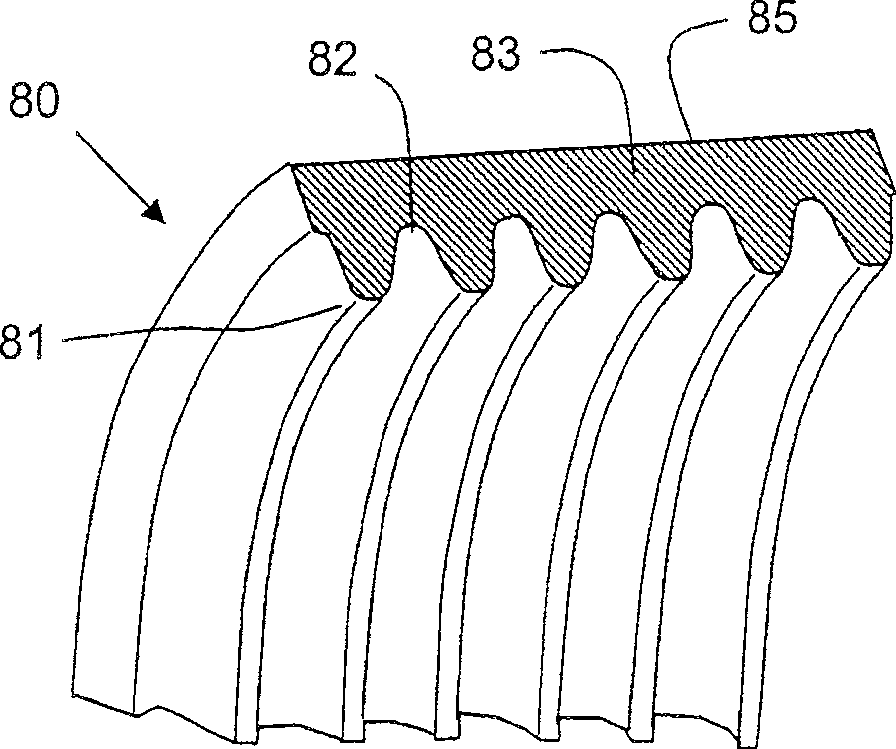

[0035] the following pair figure 1 The entire transmission configuration diagram of 1 further illustrates: the first motor 3 drives the driving wheel 6 through the main shaft 5, and the periphery of the wheel has a rib-rib-groove structure (see figure 2 ). The wedge belt 7 is tensioned by the driving pulley 6 , which drives the driven pulleys 8 , 14 , 16 , 21 in front of the draft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com