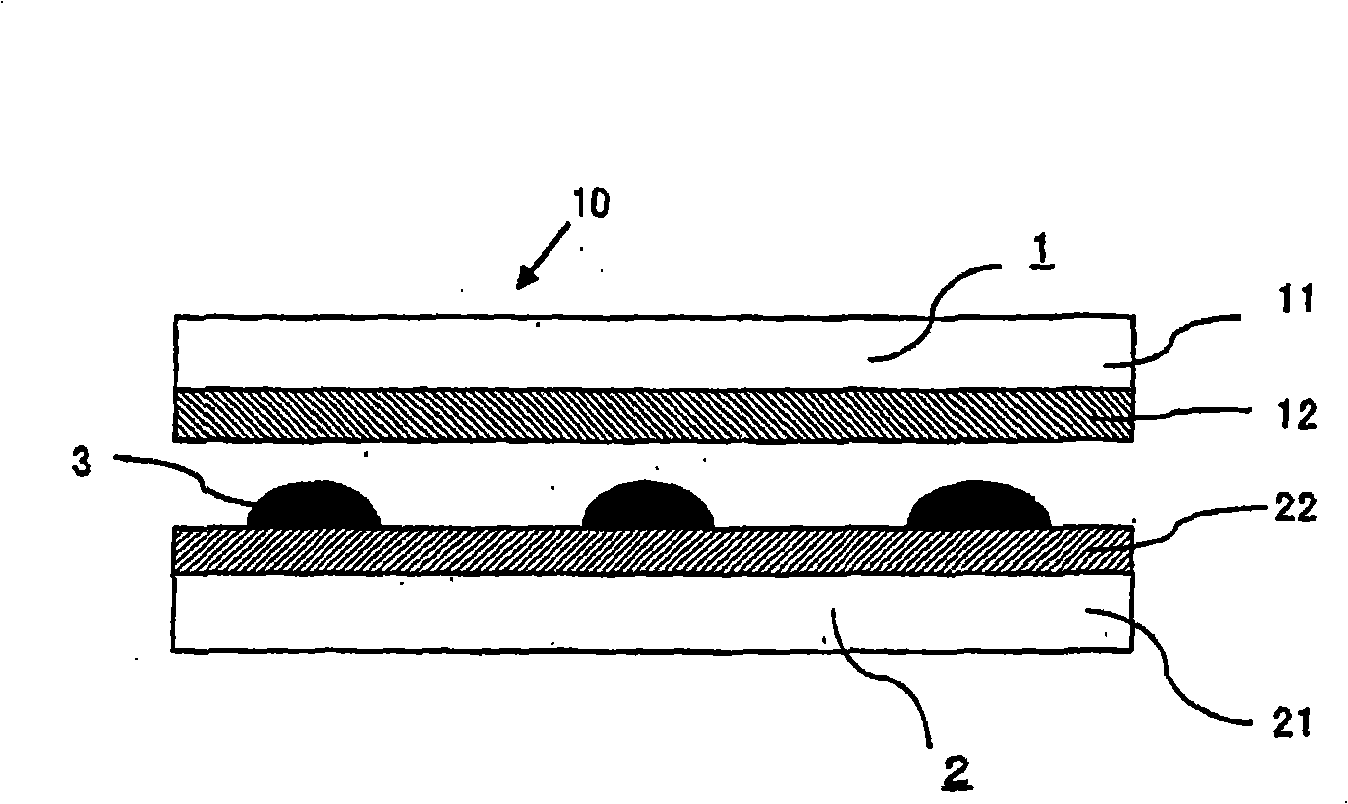

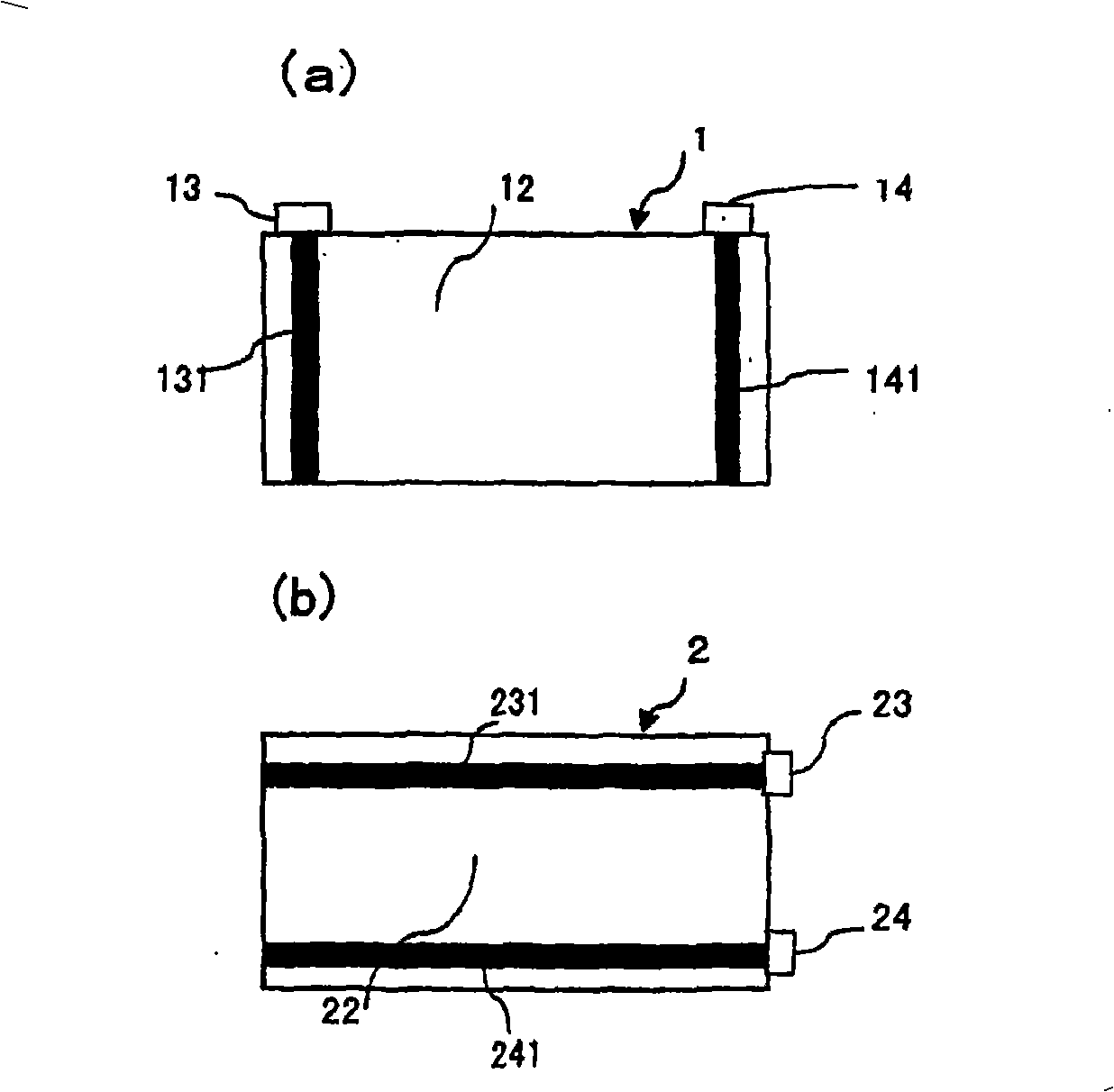

Conductive resin composition, conductive film comprising the same, and resistive-film switch employing the same

A technology of conductive resin and conductive film is applied in the field of conductive resin composition, conductive film obtained by using the resin composition, and resistive film switch obtained by using the conductive film, and achieves excellent adhesion, The effect of suppressing the increase of the surface resistivity and the decrease of the surface resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

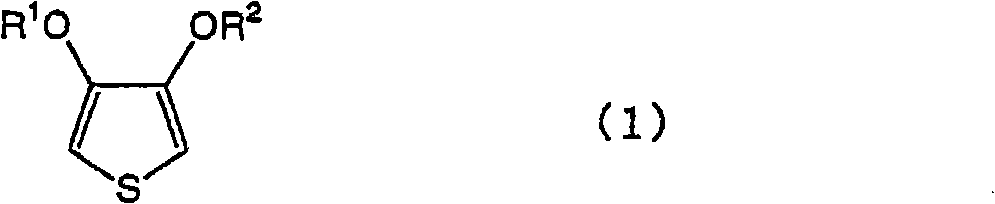

[0121] As the aqueous dispersion of a composite of poly(3,4-ethylenedioxythiophene) and polystyrenesulfonic acid, Baytron PH500 manufactured by H.C. Starck (hereinafter referred to as aqueous dispersion (A)) was used. The electrical conductivity of this complex was measured and found to be 0.79 S / cm. In water dispersion (A) 10.4 parts (convert by solid content), add polyester resin aqueous dispersion (manufactured by Nagase Chemtex company, Gabsen ES-210) 3.0 parts (convert by solid content), melamine series cross-linking agent (Sumitomo Chemical production, Sumitex ResinM-3) 1.0 parts (converted by solid content), 20 parts of N-methylformamide, a small amount of surfactant, a small amount of leveling agent, an appropriate amount of water and modified methanol, stirred for 1 hour, Then, it filtered using the 400-mesh SUS sieve, and obtained the coating agent.

Embodiment 2

[0124] Except that the amount of the aqueous dispersion (A) is changed to 10.7 parts (converted by solid content), and the amount of the polyester resin aqueous dispersion is changed to 9.0 parts (converted by solid content), the same operation as in Example 1 , to prepare the coating agent.

Embodiment 3

[0126] As the aqueous dispersion of a complex of poly(3,4-ethylenedioxythiophene) and polystyrenesulfonic acid, Baytron PH510 manufactured by H.C. Starck (hereinafter referred to as aqueous dispersion (B)) was used. The electrical conductivity of this complex was measured and found to be 0.67 S / cm. A coating agent was obtained in the same manner as in Example 1, except that this water dispersion was used and the amount of the melamine-based crosslinking agent was changed to 3.0 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com