Explosion isolation type low-voltage explosion-proof power generator

A generator and explosion-proof technology, which is applied in the direction of synchronous generators, electromechanical devices, electrical components, etc., can solve the problems of lack of low-voltage power generation explosion-proof and explosion-proof technology, many leads in the junction box, and difficulty in meeting the requirements of explosion-proof, etc., to achieve Safe and reliable power generation operation, good heat dissipation effect, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

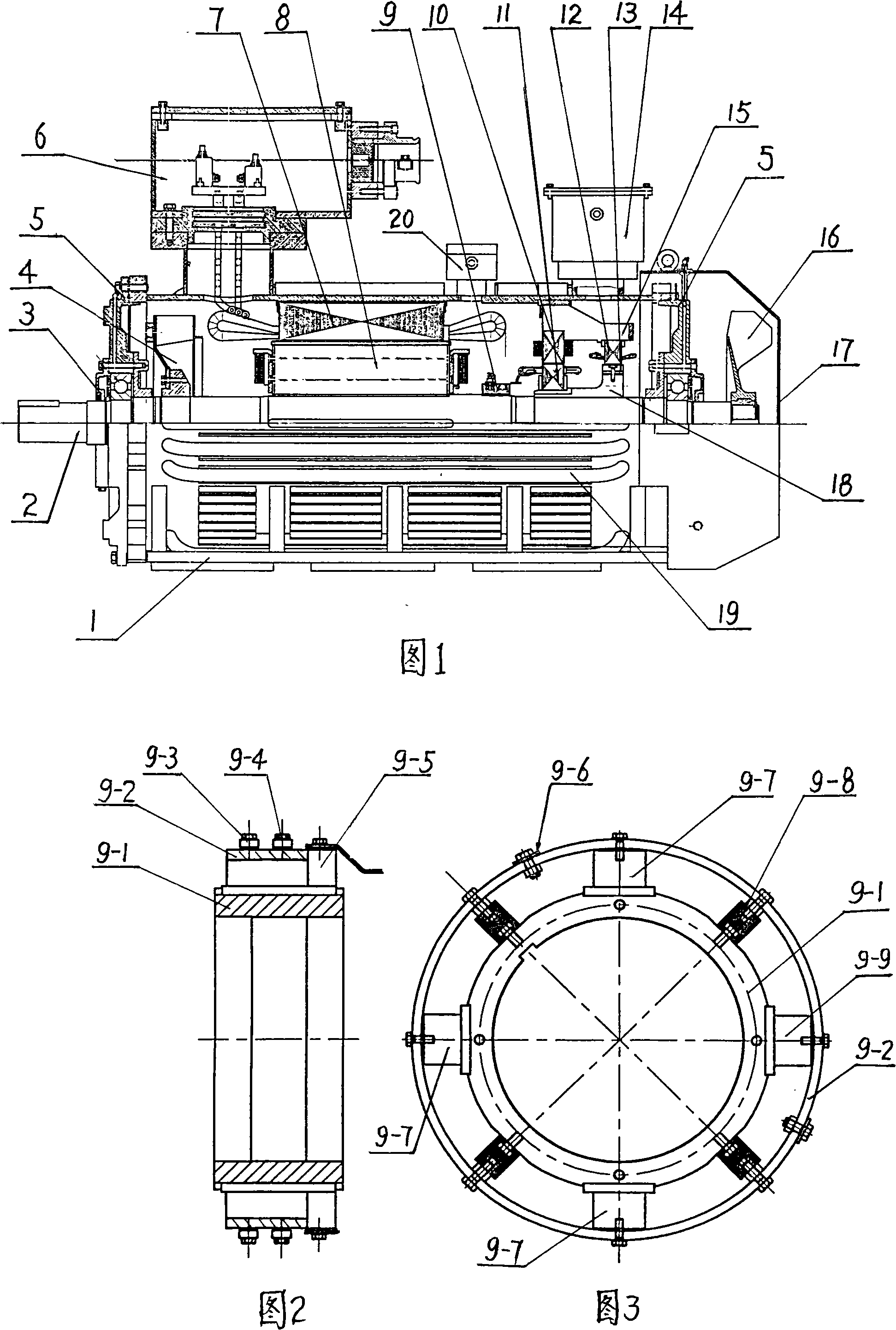

[0022] Referring to Fig. 1, the flameproof low-voltage explosion-proof motor of the present invention comprises a main generator, an AC exciter and a permanent magnet auxiliary exciter, wherein the main generator consists of a base 1, a main generator stator 7 and a main generator rotor Composed of 8, the main generator stator 7 is tightly fitted and connected with the machine base 1, so that the heat generated by the main generator stator 7 during operation can be dissipated through the conduction of the outer wall of the machine base, and at the same time, the circumferential parts of the main generator stator core are evenly arranged There are many axial ventilation holes, and together with the air gap of the main generator, it constitutes the cooling air path of the stator 7 of the main generator, so as to cool the stator 7 of the main generator well. The main generator rotor 8 has a salient pole sleeve structure, and its magnetic pole punching piece is formed by integral s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com