Backlight module frame and its assembling method

A backlight module and frame technology, which is applied in the field of backlight module frame and its assembly, can solve the problems of low reusability, high mold complexity, high mold opening cost and time, so as to reduce mold opening cost, increase heat dissipation area, and help The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

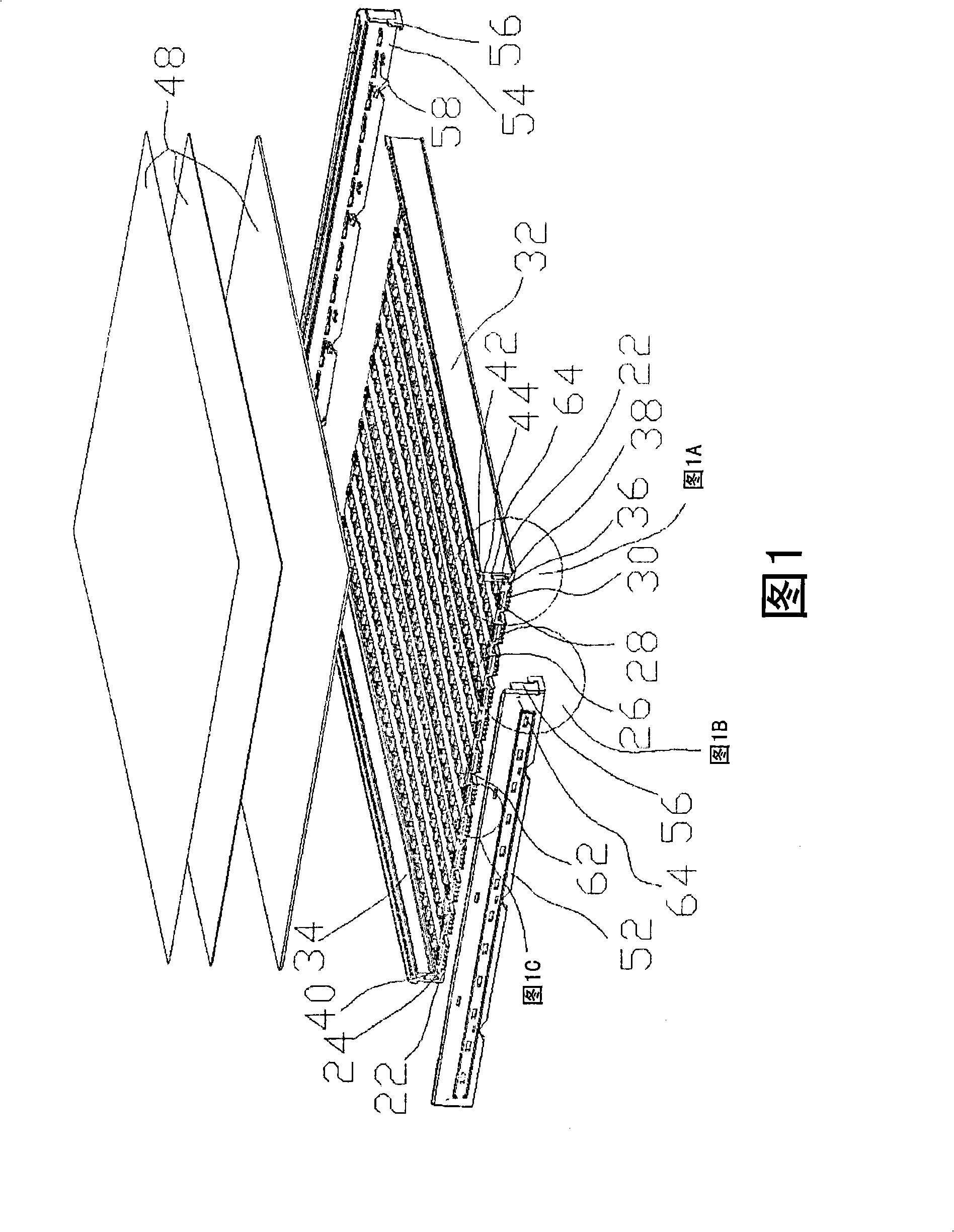

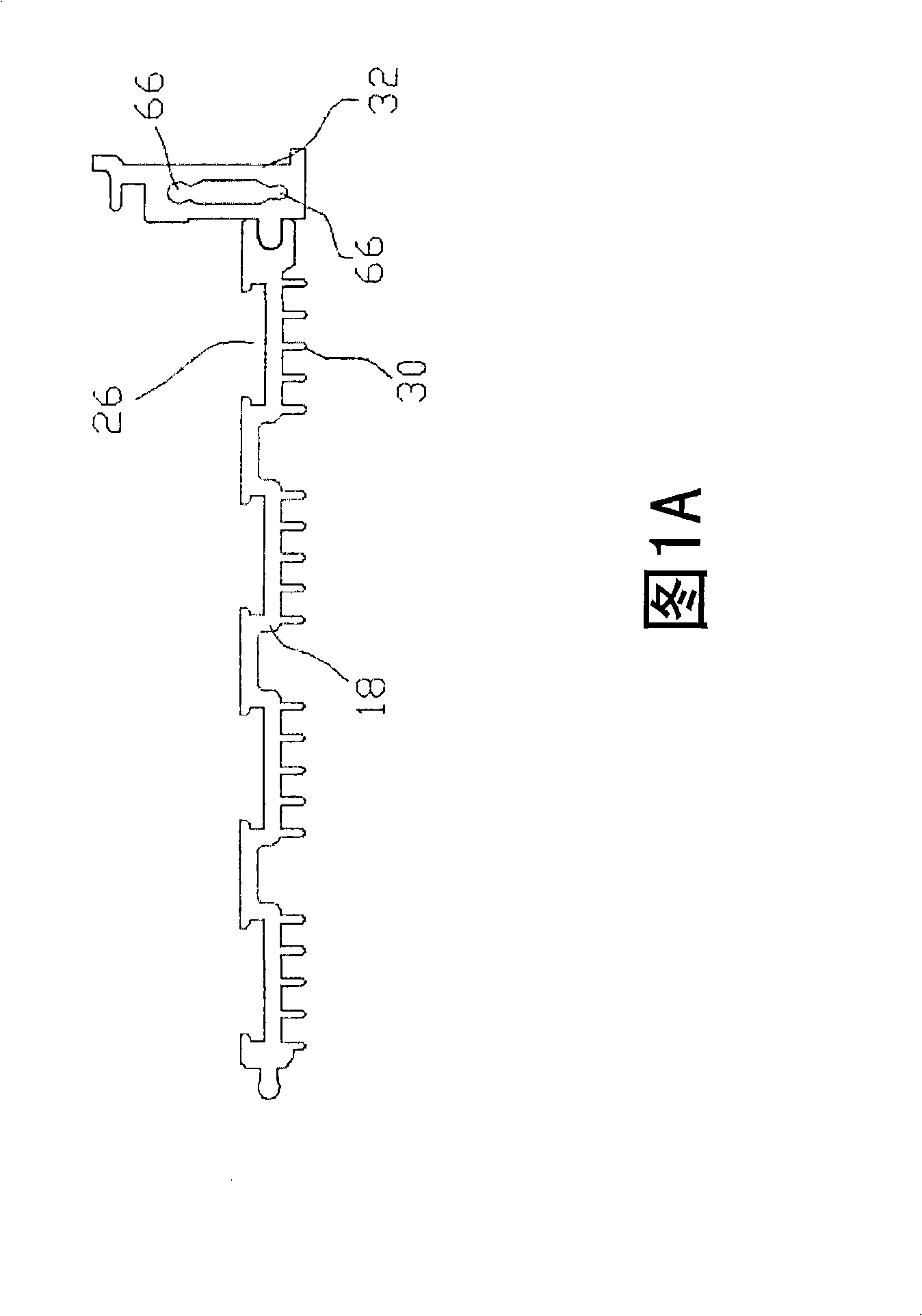

[0021] The present invention modularizes the frame structure of the backlight module through the concept of modularization and adopts a single cross-section structure design. The board body part of the frame is assembled to form the required size, and around the board body, respectively The baffle and the side panels are installed to form the frame of the backlight module; the baffle is provided with a groove and a supporting plate, which can be used for arranging the optical film group.

[0022] The frame of the backlight module of the present invention can be applied to a direct-type backlight module (as shown in FIG. 1 ) or a side-type backlight module (as shown in FIG. 9 ). The present invention will be described below using an embodiment of an LED backlight module; firstly, an embodiment of a direct-type backlight module will be described, please refer to FIG. 1 , FIG. 1A-FIG. 1C, FIG. 2 , and FIG. 3 . As shown in the figure, the modularized backlight module of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com