Idle rotation tolerable plastic magnetic force pump

A magnetic pump and plastic technology, applied in the field of disc-shaped impeller driven magnet sets, idling-resistant plastic magnetic pumps, and transporting corrosive liquid media, it can solve the problems of not allowing particles, not idling resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

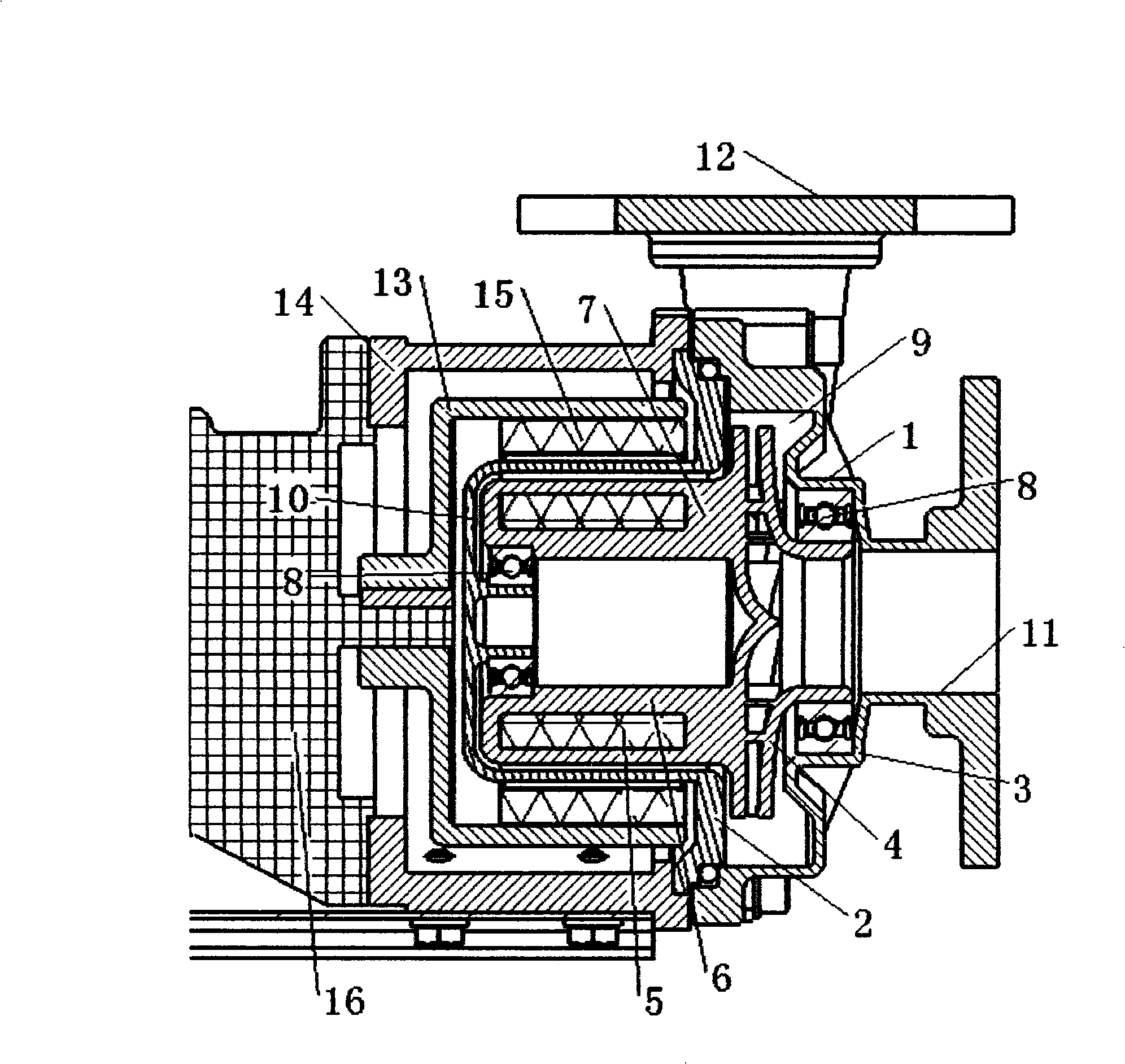

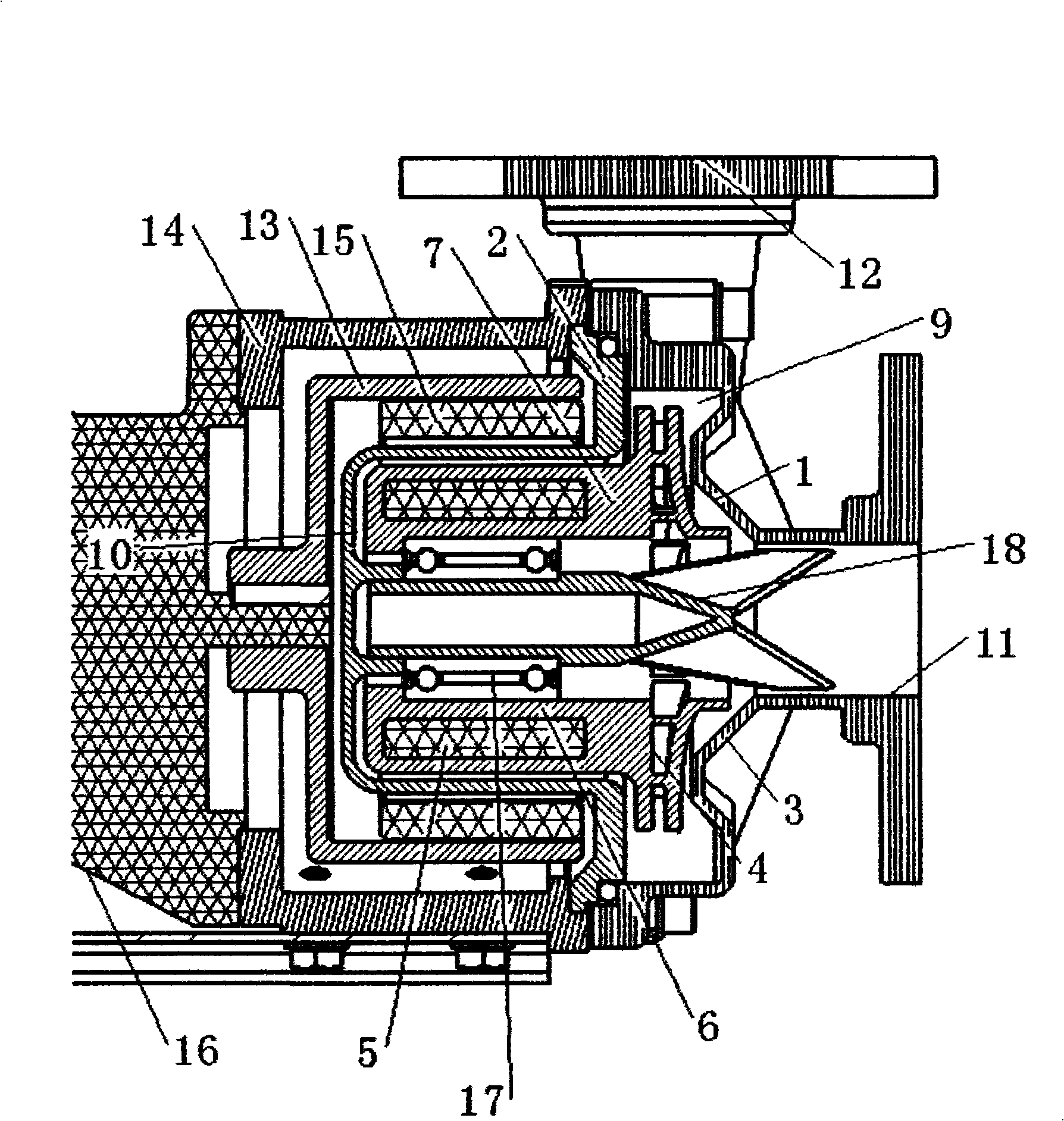

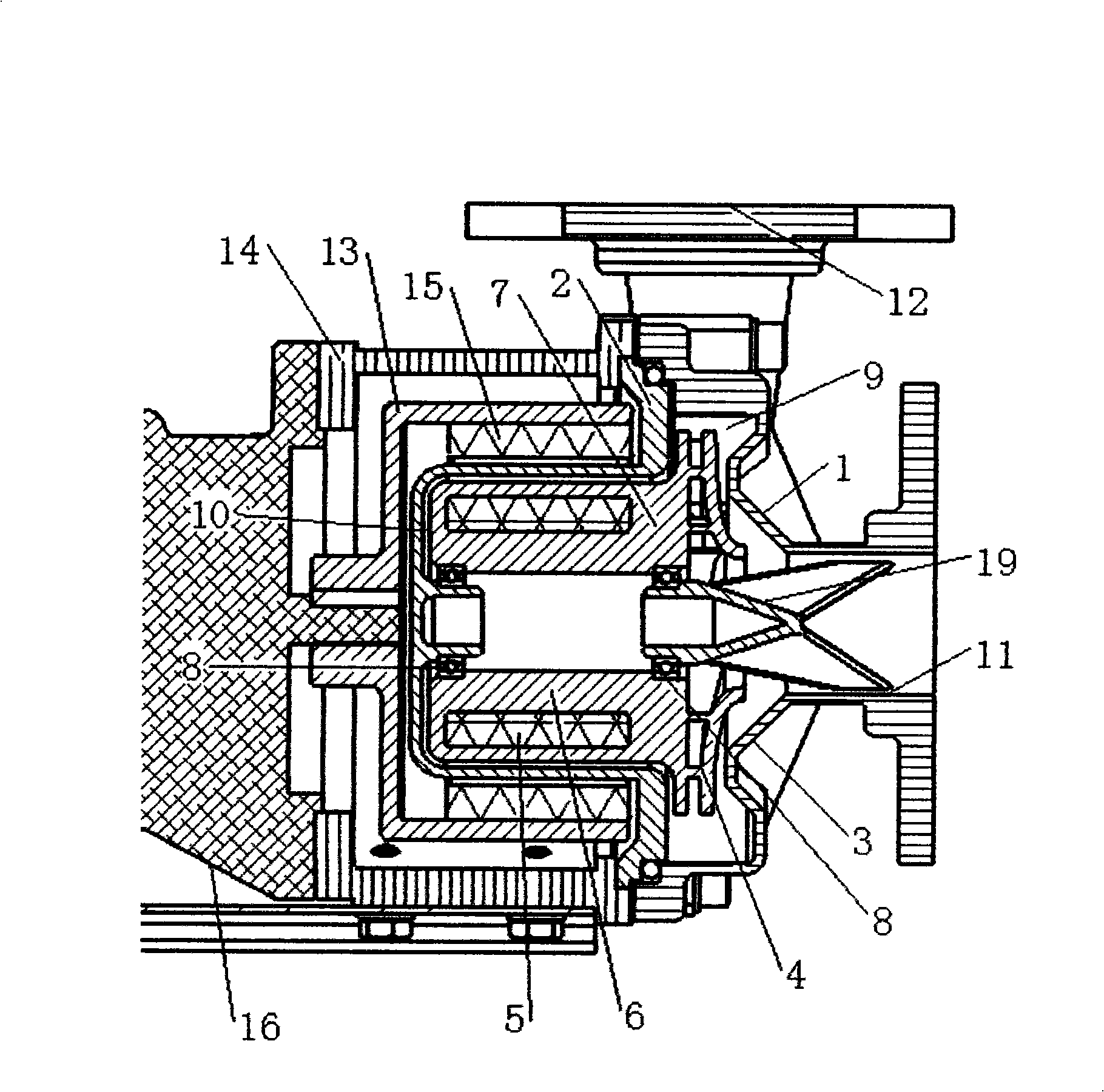

[0015] Three preferred embodiments of the present invention are described below with reference to the accompanying drawings.

[0016] like figure 1 As shown, the first embodiment of the idling-resistant plastic magnetic pump of the present invention includes a plastic pump casing (3) divided into a front pump casing (1) and a rear pump casing (2), and an impeller chamber (9) and its interior are formed It is adjacent to the driven magnet chamber (10), and has an inlet (11) and an outlet (12) for the delivery of the target liquid. The disc-shaped impeller driven magnet set (7) is made up of the disc-shaped impeller (4) at the front end and the magnet cover (6) at the rear end, and the driven magnet (5) is installed inside the magnet cover (6). The disc-shaped impeller driven magnet set (7) is installed inside the impeller chamber (9) formed inside the pump casing (3) and the driven magnet set chamber (10) adjacent thereto. The outer wall of the protruding part of the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com