Process control device of CAST step-feed and further denitrification and method

A technology of deep denitrification and staged water inflow, applied in aerobic and anaerobic process treatment, etc., can solve problems such as operation mode is not optimal, excessive aeration reaction time, influence of nitrogen removal efficiency, etc., to save external investment. Carbon source amount, good denitrification effect, and the effect of solving the improvement of operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

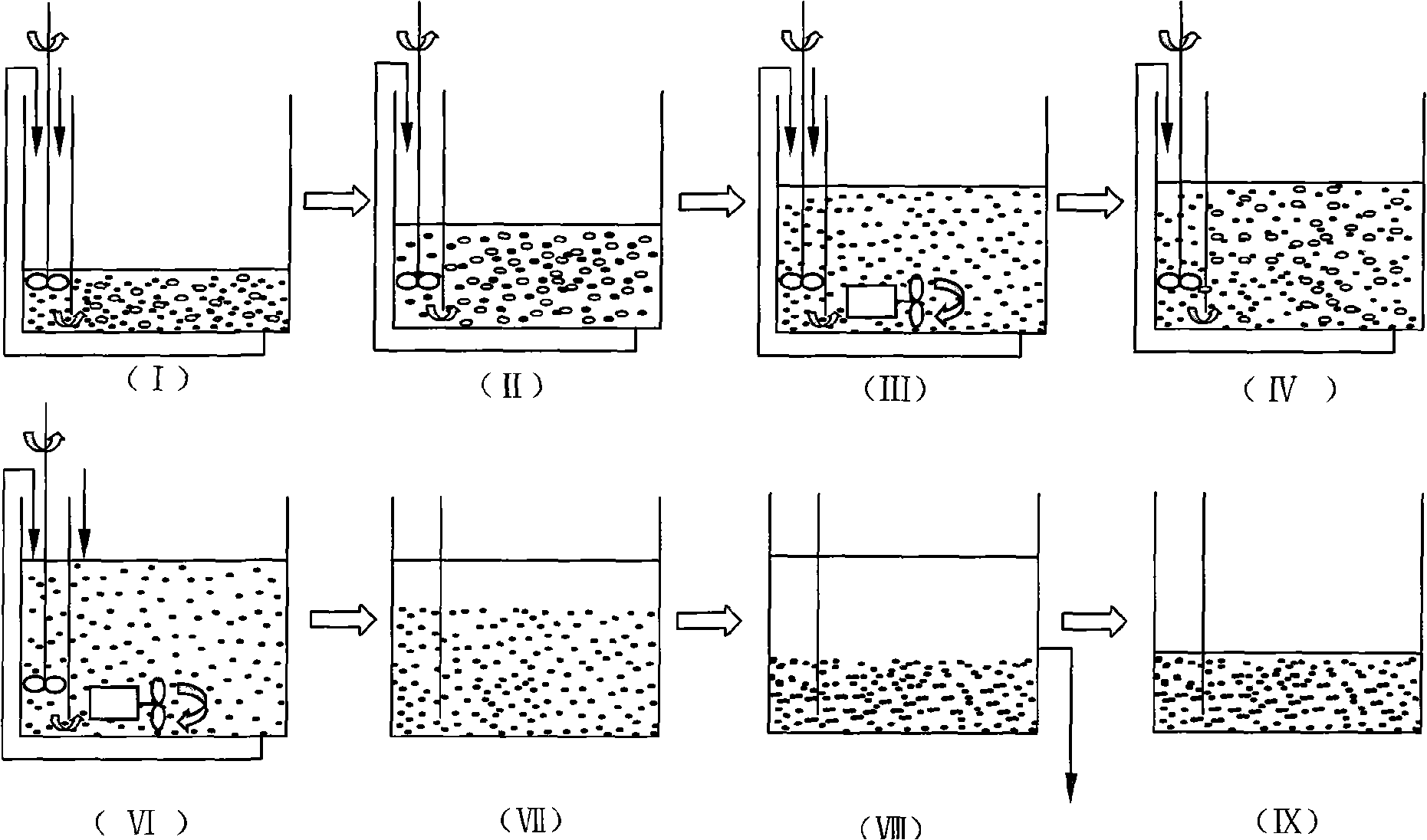

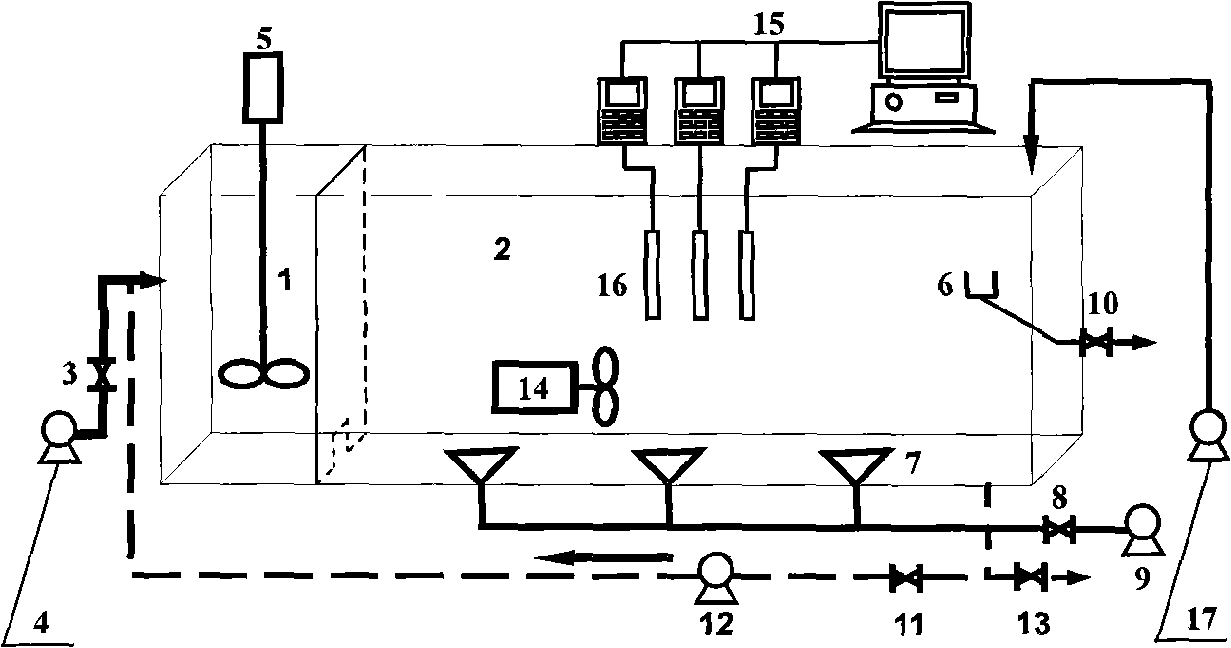

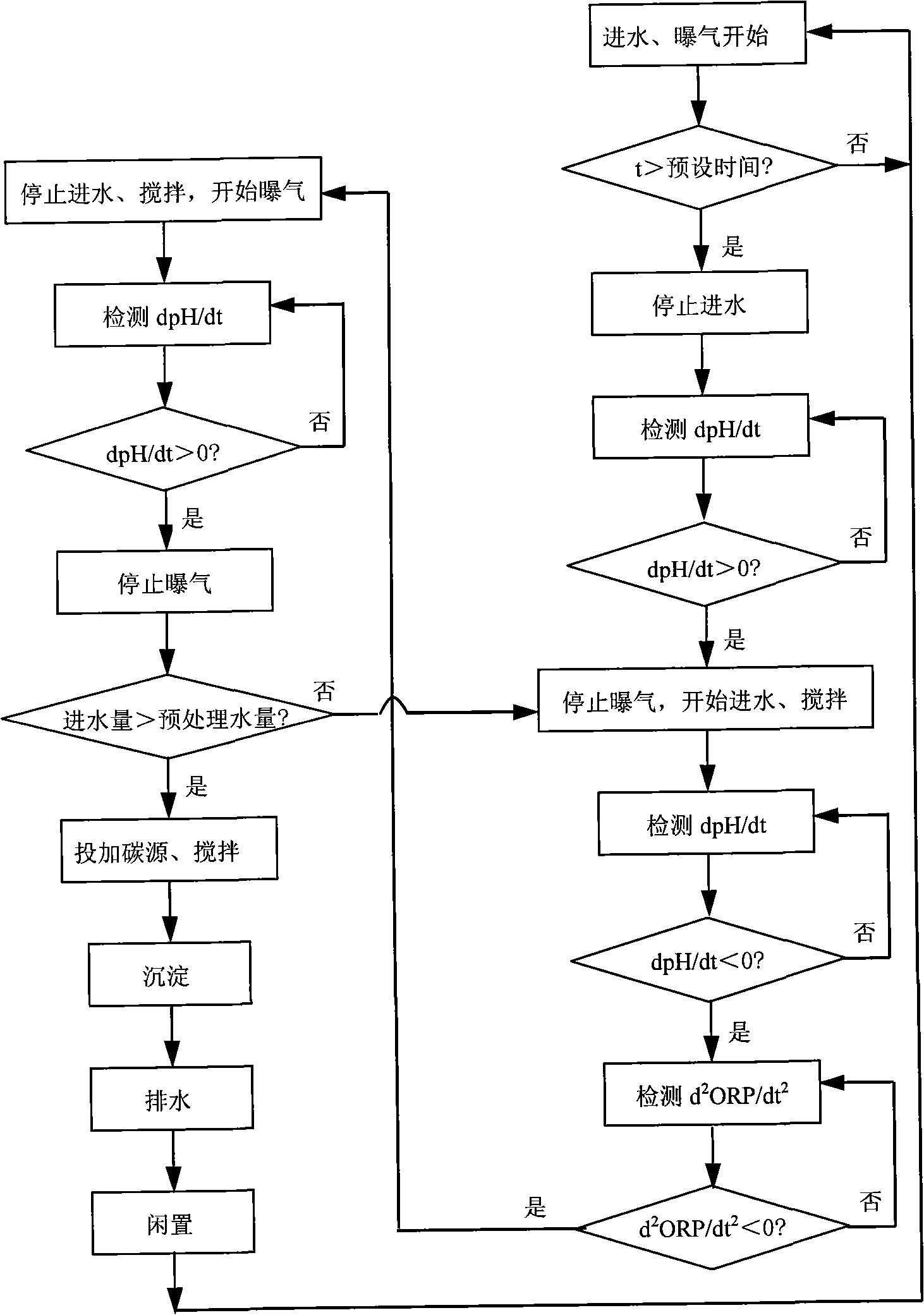

Method used

Image

Examples

Embodiment

[0053] The actual domestic sewage discharged from a family area of a certain university was used as the experimental object (pH=6.5~7.8, COD=260~350mg / L, TN=60~85mg / L). The selected CAST reactor has an effective volume of 18L, the initial MLSS in the reactor is 3.5-4.0g / L, and the aeration rate is constant at 0.1m 3 / h, the mud age is maintained at about 15d, and the reaction temperature is 23°C. Using the CAST segmented influent deep denitrification process and process control device, the treated water volume is 8L, and the number of segments is 2 times. The COD in the final effluent water is less than 50mg / L, and the total nitrogen is less than 5mg / L, which is far lower than the national first-level discharge standard. total nitrogen concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com