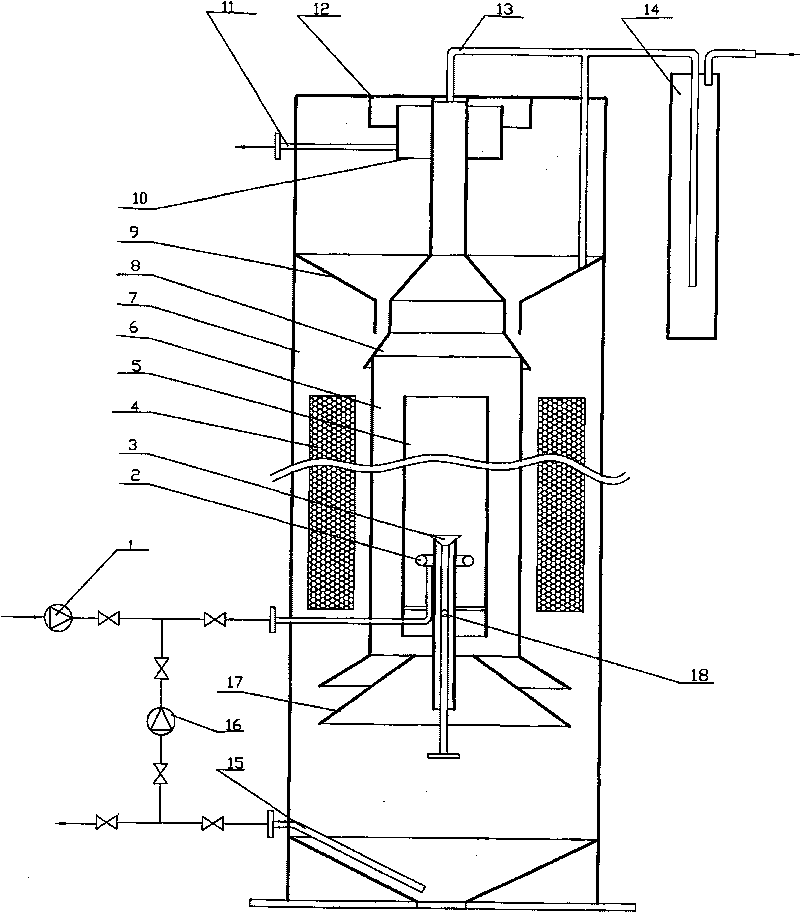

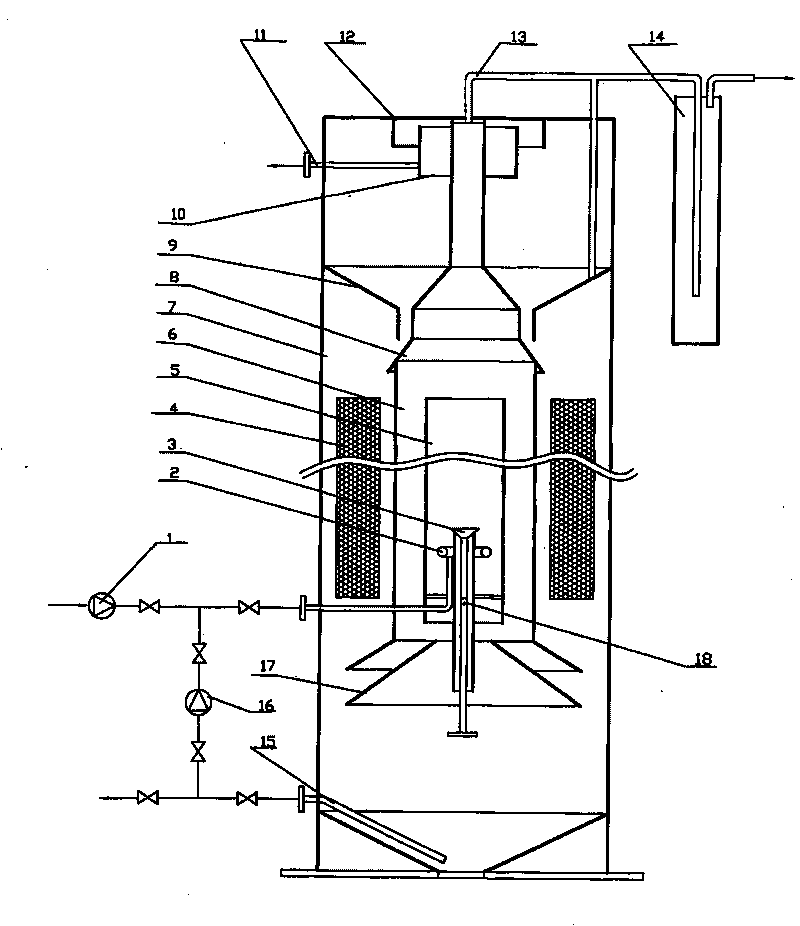

Double-cycling anaerobic reactor

An anaerobic reactor and double-cycle technology, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of complex water distribution system, high energy, and high suspended solids, so as to ensure degradation efficiency, reduce power consumption, and save energy. The effect of circulating energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technology of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0014] The double-cycle anaerobic reactor as shown in the figure includes a reactor housing 7, a sewage lifting pump 1 arranged outside the housing, a backflow circulation pump 16, a pipeline valve and an outlet pipe 11 for connection, and a backflow circulation pump 16 The connected mud discharge return pipe 15 and the elastic packing 4 arranged in the shell are characterized in that: the center of the reactor shell 7 is provided with a concentric or symmetrical baffle ascending guide cylinder 5 and a descending liquid guide cylinder 6 sequentially from the inside to the outside and filler 7; the bottom of the liquid-rising guide tube 5 is provided with a water inlet distribution pipe 2 connected to the sewage lifting pump 1 and a biogas lifting reflux device 3; The upper part of the downcomer guide tube 6 is provided with a central a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com