Apparatus for homogenizing light

A technology of uniform light and lens array, applied in optics, optical components, instruments, etc., can solve the problem of insufficient numerical aperture, and achieve the effect of low cost and large numerical aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

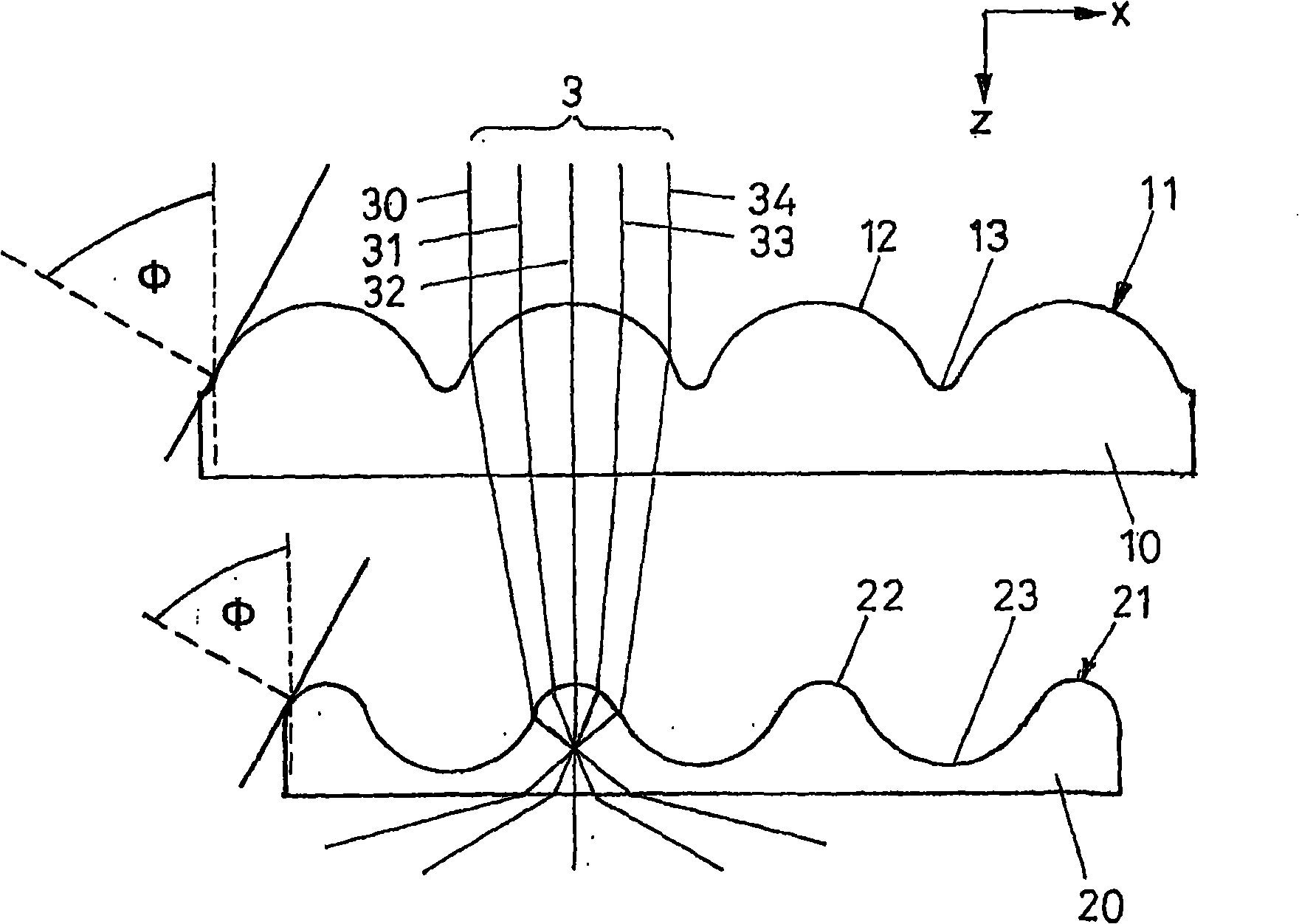

[0019] In an alternative embodiment not explicitly shown here, there is the possibility that the light exit surface of the first substrate 10 is equipped with a further lens array. The lens array may, for example, comprise cylindrical lenses whose cylindrical axes may be oriented perpendicularly to the cylindrical axes of the cylindrical lenses of the first lens array 11 .

[0020] The second substrate 20 , which is spaced apart from the first substrate 10 in the direction of beam propagation (z direction), has a second lens array 21 on a light entry surface facing the light exit surface of the first substrate 10 . In this exemplary embodiment, the light exit surface of the second lens array 21 is also realized flat or at least substantially flat. It can be seen that the second lens array 21 comprises a first lens 22 realized with a convex surface and a second lens 23 realized with a concave surface, which in this embodiment are likewise cylindrical lenses whose cylindrical ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com