Method for testing nitroaniline content

A technology for the detection of p-nitroaniline, which is applied in the direction of material analysis by observing the influence of chemical indicators, measurement of color/spectral characteristics, analysis by making materials undergo chemical reactions, etc., which can solve the problem of too narrow solubility range, Incomplete dissolution, affecting the accuracy of measurement results and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific steps of sample preparation and detection operation involved in the present invention are as follows:

[0020] 1), the preparation of detection reference substance stock solution:

[0021] Accurately weigh about 0.05 grams (g) of analytically pure p-nitroaniline, place it in a 100 milliliter (ml) volumetric flask, add 50 milliliters (ml) of methanol, dissolve it ultrasonically, let stand and cool to room temperature, then add 0.025 mole The sulfuric acid solution per liter (mol / L) was adjusted to 100 milliliters (ml).

[0022] Take 1ml of this solution and place it in a 50ml volumetric flask, add 0.025 mol / L (mol / L) sulfuric acid solution to constant volume to 50 milliliters (ml) to obtain the detection reference substance stock solution, wherein every 1 milliliter (ml) contains p-Nitrate Aniline is about 10 micrograms (μg).

[0023] 2) Preparation of the working solution of the reference substance:

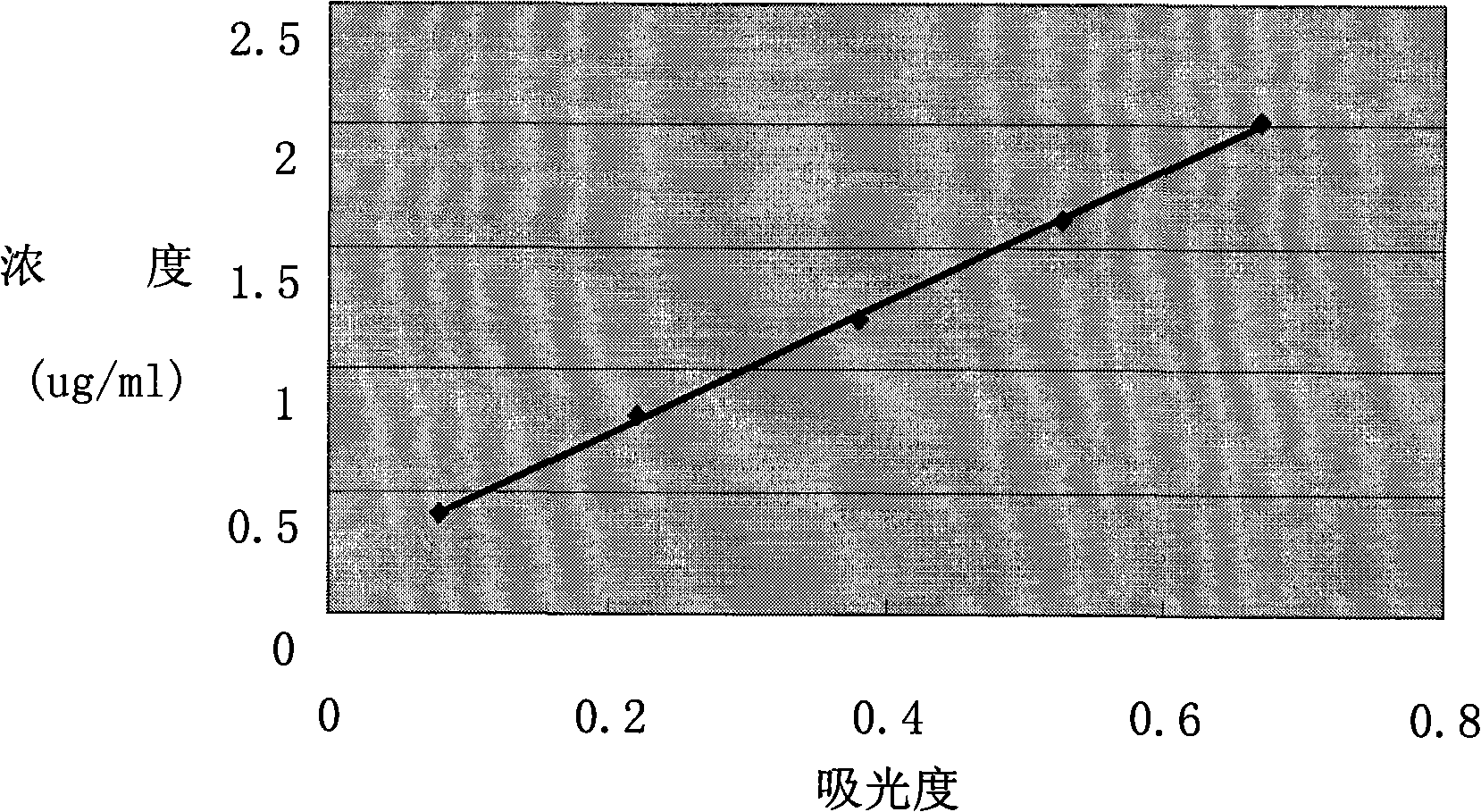

[0024] Take 15 25 milliliters (ml) graduated test tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com