Broad band damp type vibrating isolation system

A vibration isolation system and damping technology, which is applied in the direction of non-rotational vibration suppression, can solve the problems of high processing cost, large stiffness coefficient, and large metal stiffness, and achieve the effects of strong installation adaptability, strong supporting capacity, and wide frequency range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

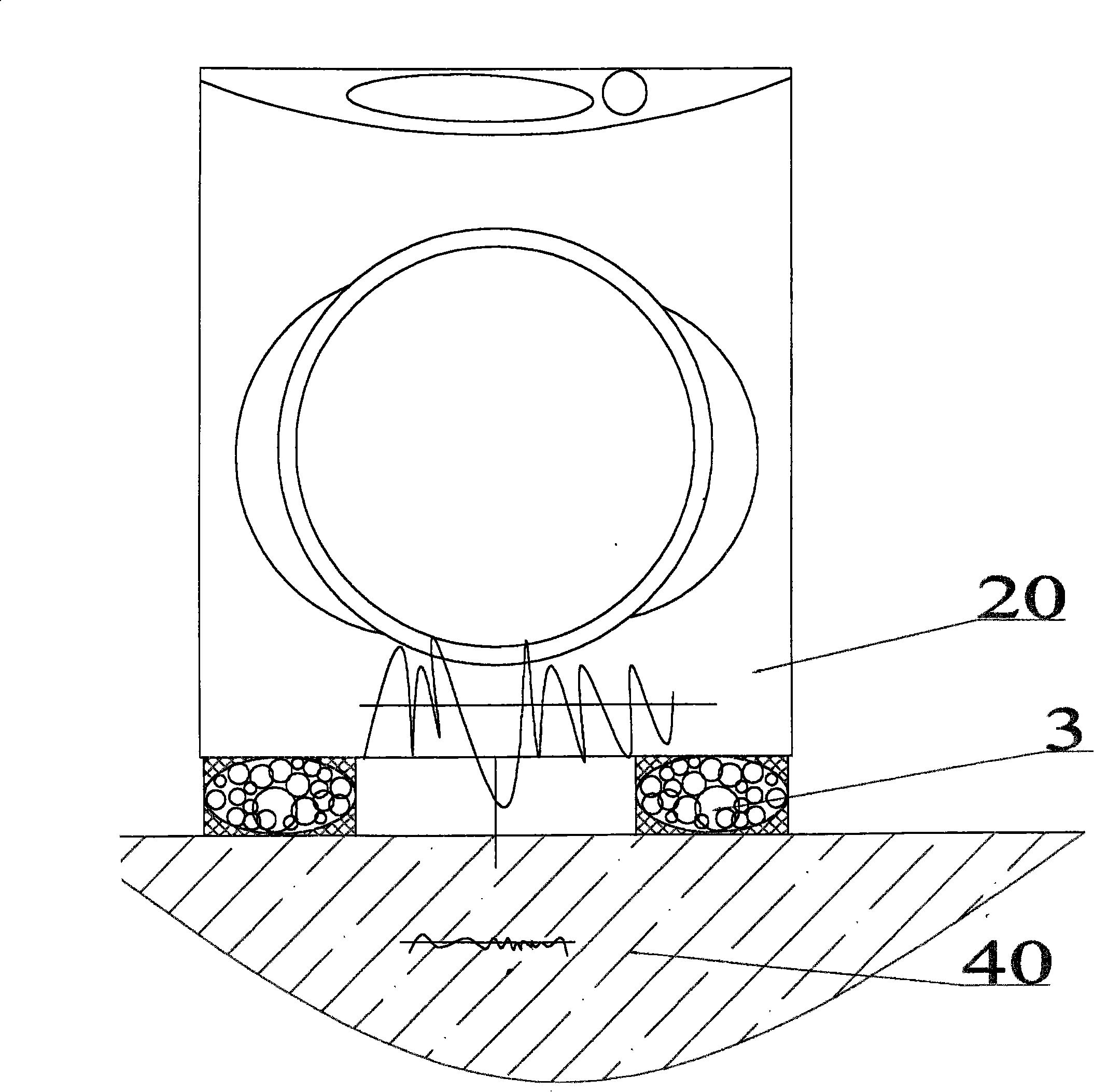

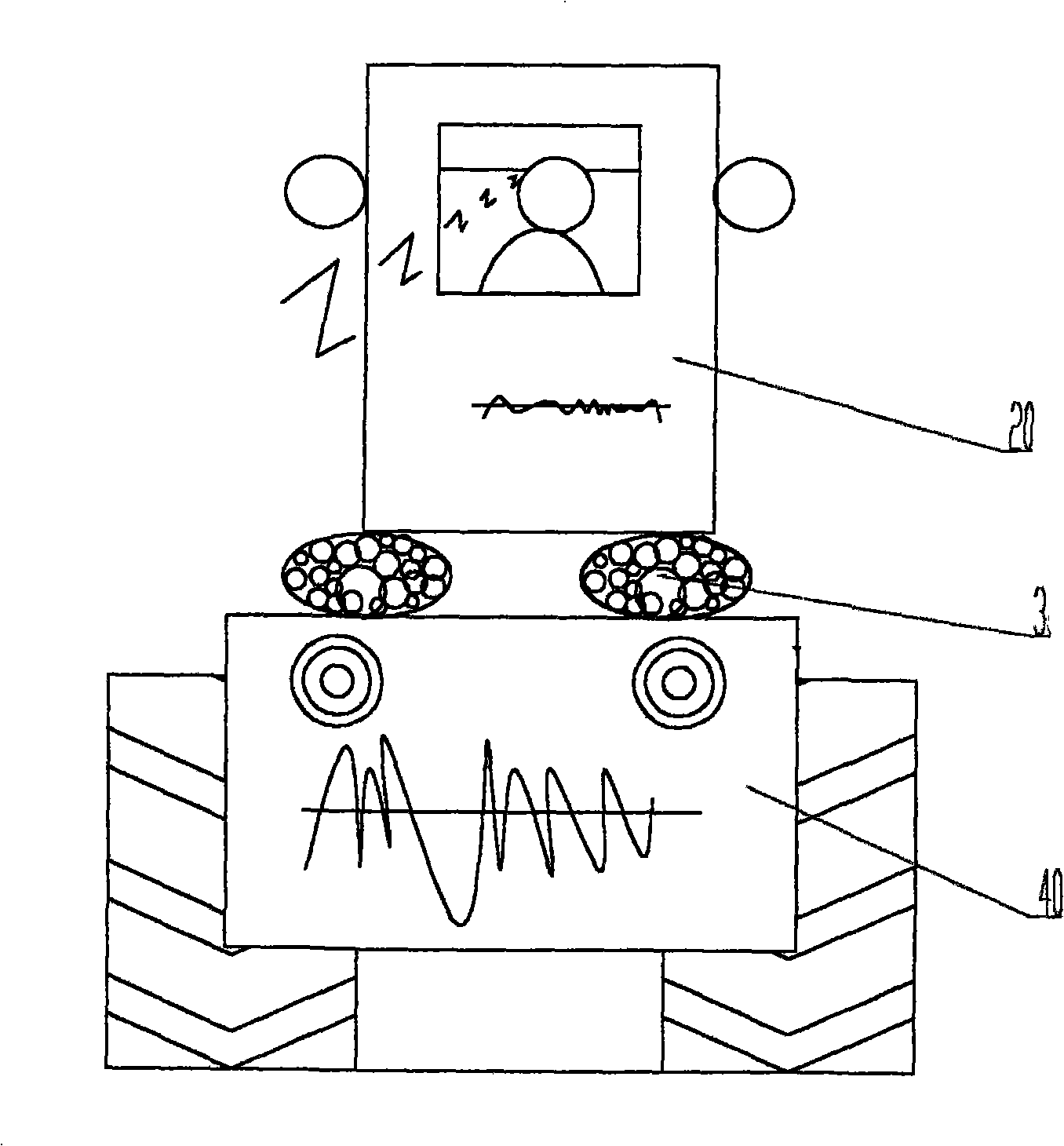

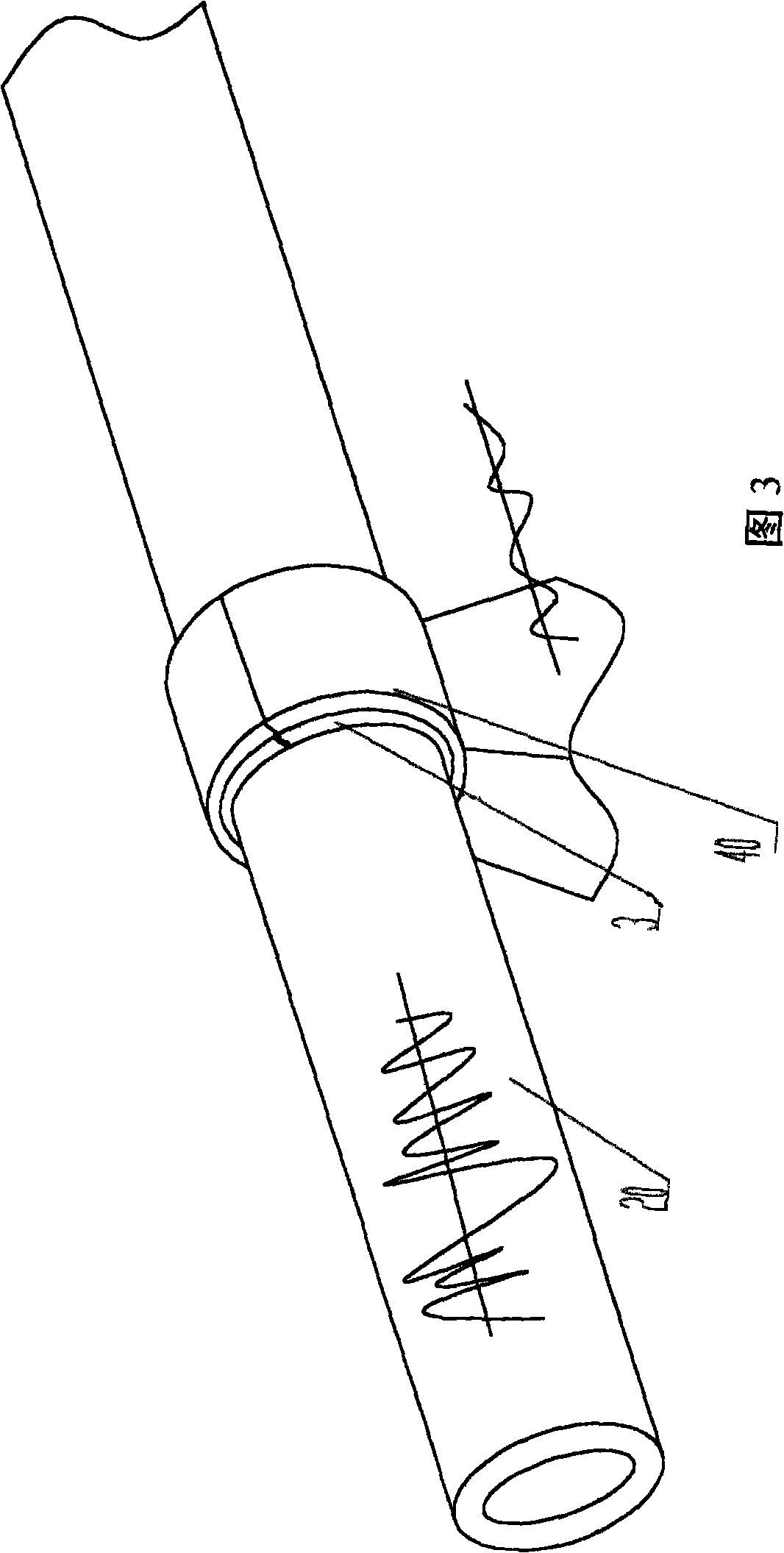

[0099] Will Figure 12 The broadband damping type vibration isolator shown is applied to a drum washing machine to replace the traditional feet.

[0100] 1) wherein the elastic housing 86 is made of metal material, and the elastic vibration isolator has a rubber-plastic elastic material with a stiffness of about 100Kgf / mm; the particles are surface-treated iron powder with irregular shapes; the iron powder The particle size range is 0.0001 micron to 1 mm; the filling amount is 80%;

[0101] 2) wherein the elastic shell 86 is made of metal material, and the elastic vibration isolator has a rigidity of about 200Kg / mm rubber-plastic elastic material; the particles are surface-treated iron powder with irregular shapes; the iron powder The particle size range is 1 micron to 0.5 mm; the filling amount is 100%;

[0102] 3) wherein the elastic shell 86 is made of metal material, and the elastic vibration isolator has a rigidity of about 150Kgf / mm rubber-plastic elastic material; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com