Components proportions of nylon plastics flexibilizer and production process thereof

A nylon plastic and toughening agent technology, which is applied in the field of nylon plastic toughening agent, can solve the problems of affecting the grafting rate of the product, the quality of nylon plastic toughening agent is not improved, the efficiency of the initiator is decreased, etc., so as to improve compatibility. The effect of improving property and interfacial affinity, elasticity and reaction compatibility, improving stability and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is a nylon plastic toughening agent specially developed for toughening nylon products. The components and weight ratios of nylon plastic toughening agent Example 1 are as follows:

[0037] EPDM 100000g

[0038] Compatibilizer 1 (maleic anhydride) 900 grams

[0039] Compatibilizer 2 (propyl methacrylate) 320 grams

[0040] Initiator (diphenylbutane) 30 grams

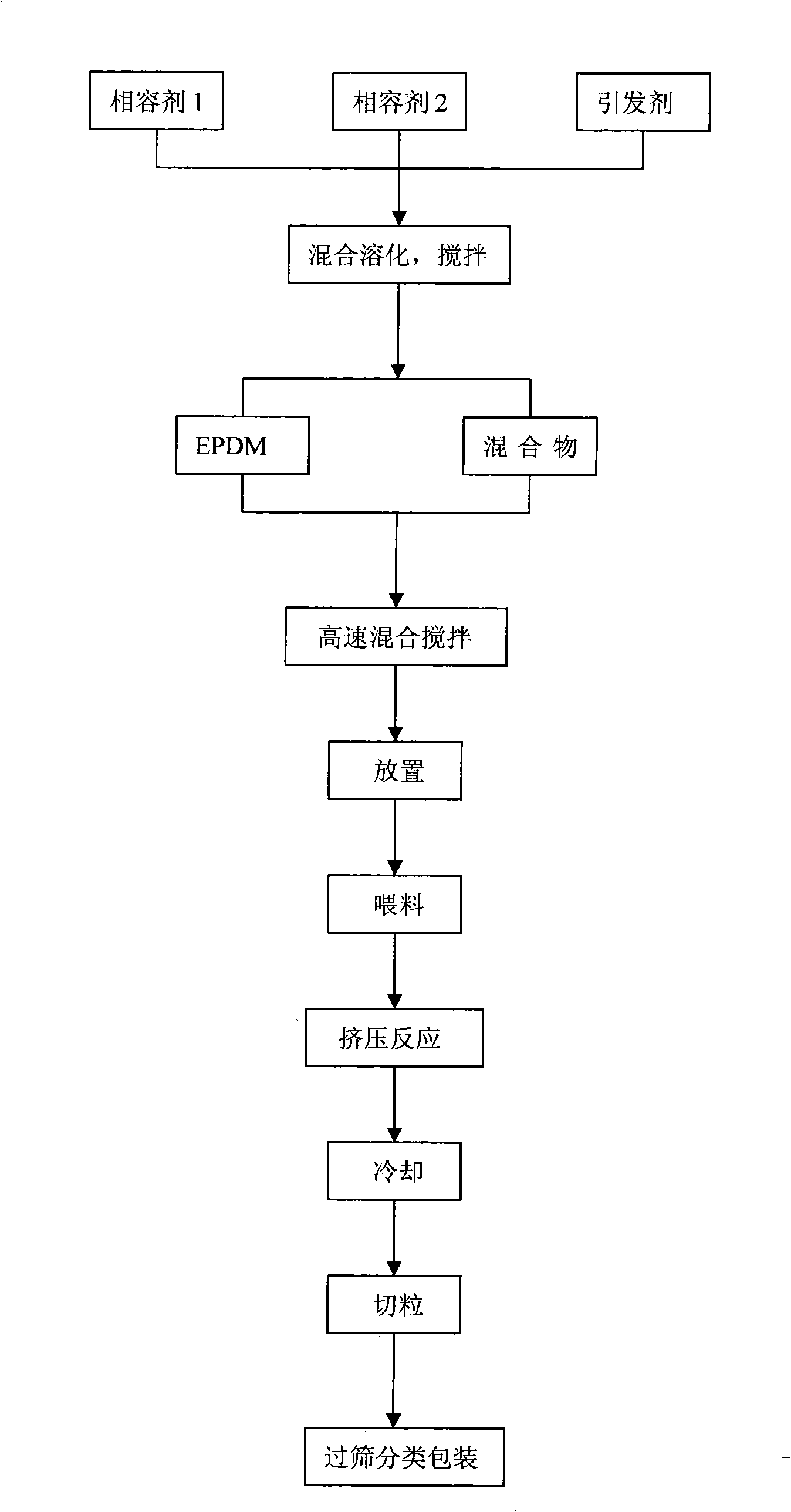

[0041] like figure 1 shown. The production process of nylon plastic toughening agent embodiment 1 is as follows:

[0042] Step 1: Measure the respective weights of maleic anhydride, propyl methacrylate and diphenylbutane according to the proportions described.

[0043] Step 2: Put maleic anhydride, propyl methacrylate and diphenylbutane in a container, mix and dissolve, and stir for 1 minute to obtain a mixture.

[0044] Step 3: Measure out the weight of EPDM according to the ratio of EPDM, and carry out high-speed mixing and stirring with the blend through a high-speed mixer. After stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com