Milling machine for processing single screw compressor rotor

A technology of screw compressor and processing sheet, which is applied in metal processing mechanical parts, milling machine equipment, details of milling machine equipment, etc., can solve problems such as processing problems that have not yet been realized, and achieve the effect of fast processing speed and high processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

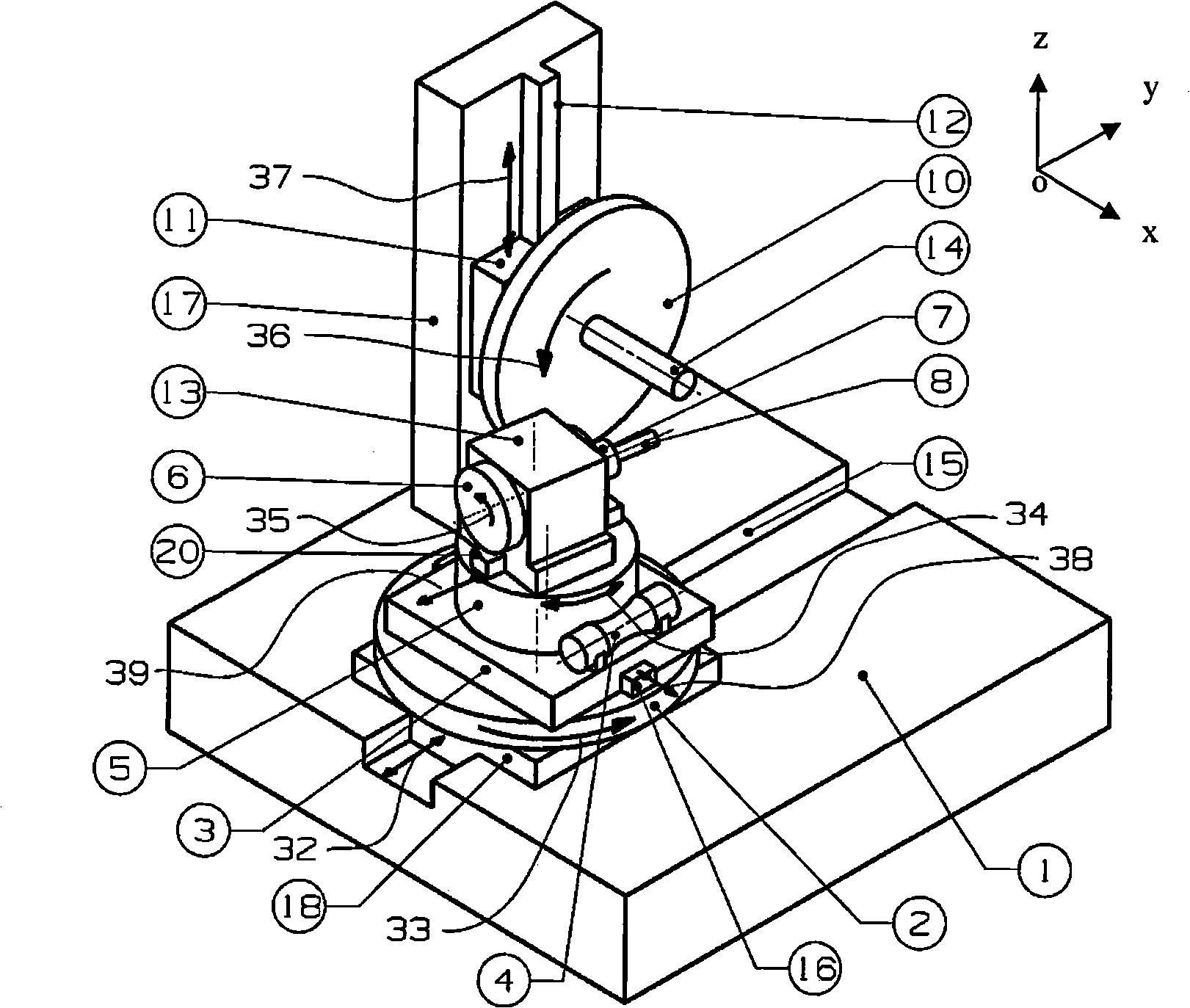

[0018] see figure 2 , the present invention includes a bed 1, a column 17 and a horizontal guide rail 15 on the bed 1. A base 18 is mounted on the horizontal guide rail 15 , and the base 18 can reciprocate along the horizontal guide rail 15 in the horizontal direction 32 . The column 17 is provided with a vertical guide rail 12, the vertical guide rail 12 is provided with a guide sleeve 11, and the guide sleeve 11 can move up and down and lock in the vertical direction 37 along the vertical guide rail 12.

[0019] Chassis 2 is housed on above-mentioned base 18, and chassis 2 is provided with horizontal guide rail 16, and slide plate 3 is housed on horizontal guide rail 16. The slide plate 3 can reciprocate along the horizontal guide rail 16 in the horizontal direction 38 . The milling cutter slewing seat 5 and the slewing drive 4 are housed on the slide plate 3 . Driven by the rotary drive 4 , the milling cutter turret 5 can rotate reciprocally around its axis in its circu...

Embodiment 2

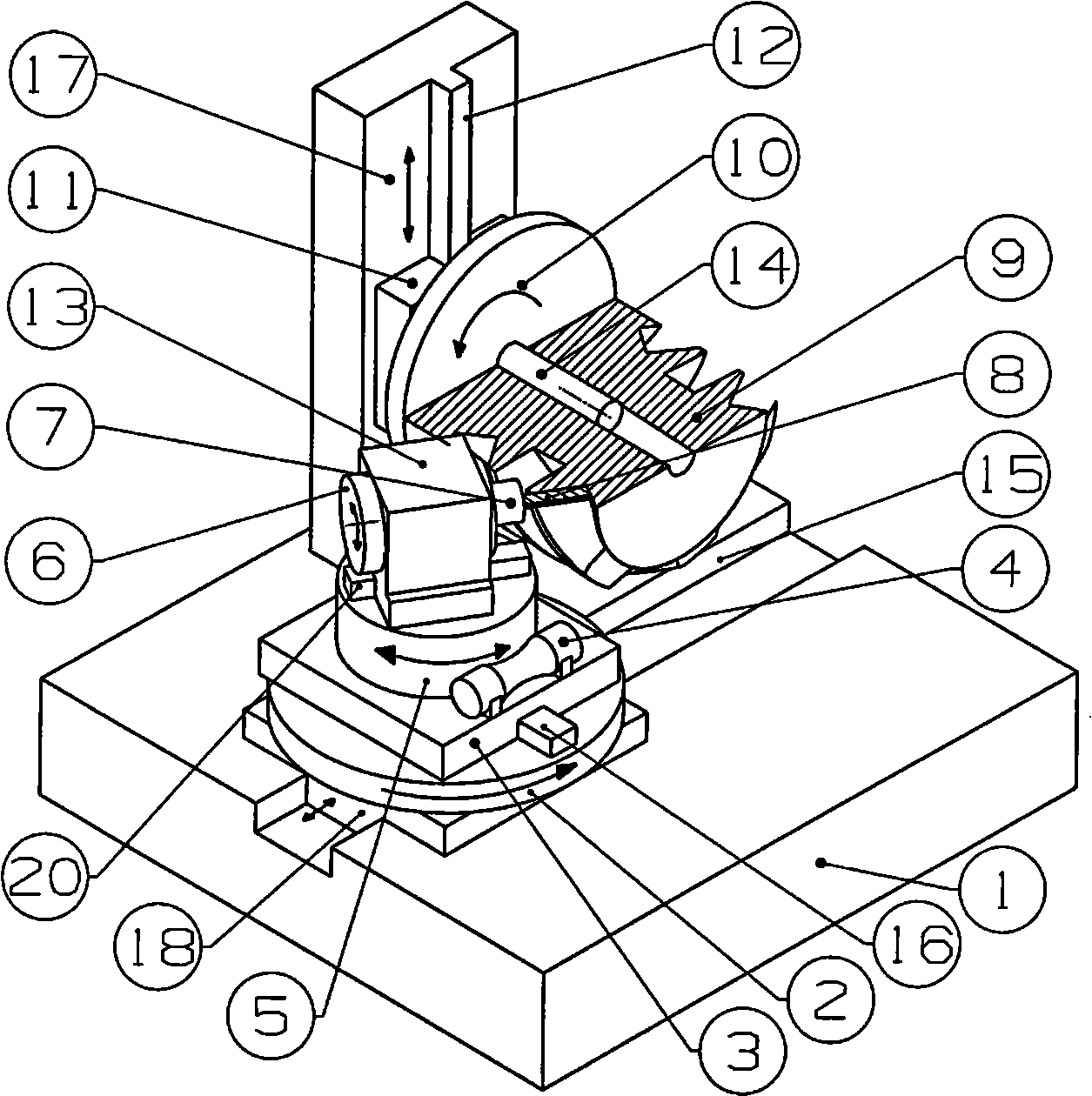

[0031] see Figure 8 , the present invention comprises bed 1, and vertical column 22 and horizontal guide rail 15 on the bed. A base 18 is installed on the horizontal guide rail, and the base 18 can move back and forth in the horizontal direction 32 along the horizontal guide rail 15 . Upright garden column 22 can move up and down along vertical direction 26, and is fixed as locking.

[0032] Above-mentioned base 1 is equipped with chassis 2, and chassis is provided with horizontal guide rail 16, and slide plate 3 is housed on horizontal guide rail 16. The chassis 2 is continuously rotatable as a whole in a circumferential direction 33 about a vertical axis. The slide plate 3 can reciprocate along the horizontal guide rail 16 in the horizontal direction 38 . The milling cutter rotary seat 5 is housed on the slide plate 3 . The milling cutter turret 5 is reciprocally rotatable around its axis in its circumferential direction 34 .

[0033] A horizontal guide rail 20 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com