Automobile front shining lamp based on double-convex lens

A technology of automobile headlights and lenticular lenses, which is applied in lighting devices, fixed lighting devices, lighting and heating equipment, etc., can solve problems such as easy melting, improve safety and service life, reduce focus distance, eliminate Potential effect of focused sunlight melting or burning headlights and surrounding auto parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

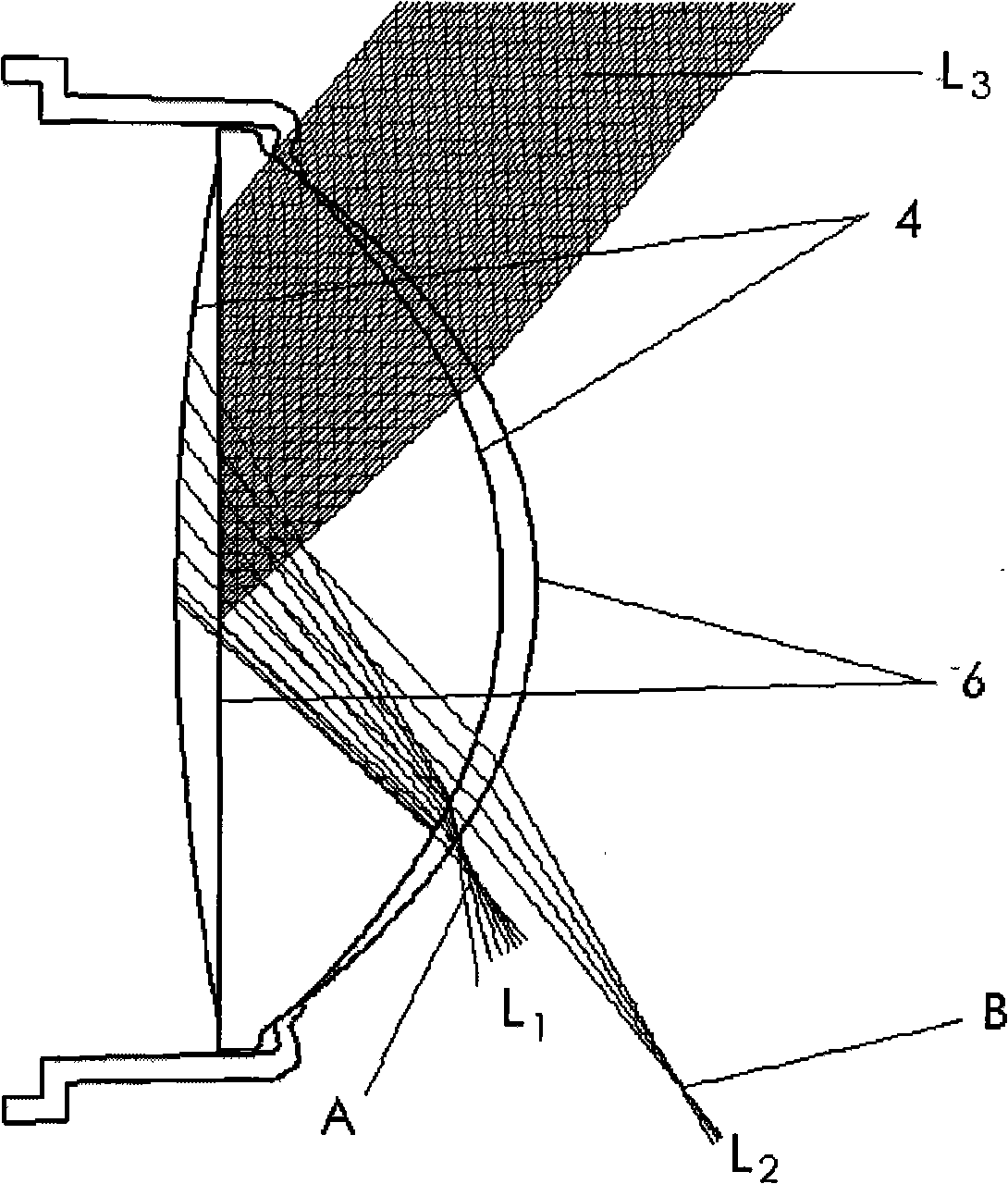

[0037] Manufactures lenticular lens headlamps. Such as figure 1 As shown, in this example, a halogen lamp or a discharge lamp is used as the light source 1, and the emitted light becomes converging after passing through the reflector 2, and the shading plate 3 acts as an aperture stop, and the light enters the biconvex lens after passing through the shading plate 3 4, the focal point of the lenticular lens 4 is designed near the shading plate, and the cut-off line is located at the 25-meter test screen. It ensures a clear cut-off line and meets the requirements of low-beam technical regulations. The lenticular lens 4 is fixed on the lamp body 8 by the lens bracket 5, which ensures the stability of the optical performance of the vehicle lamp.

[0038] In the automobile headlight based on the lenticular lens of this embodiment, the inner mirror surface of the lenticular lens is a spherical surface, and the outer mirror surface of the lenticular lens is a free-form reflective ...

Embodiment 2

[0048] In this embodiment, the convex height of the inner mirror surface of the biconvex lens is 3.3mm, and the convex height of the outer mirror surface is 22.76mm. The maximum diameter of the biconvex lens is 73.7mm. The ratio of the maximum curvature radius of the inner mirror surface to the outer mirror surface of the biconvex lens is 3.46:1. The inner mirror spherical radius is 180mm. Other than that, the same as in Example 1, the lenticular lens headlamp of the present invention was obtained.

Embodiment 3

[0050] Except in this embodiment, the convex height of the inner mirror surface of the biconvex lens is 4.1 mm, and the convex height of the outer mirror surface is 24.06 mm. The maximum diameter of the biconvex lens is 80.5mm. The ratio of the maximum curvature radius of the inner mirror surface to the outer mirror surface of the biconvex lens is 4.2:1. The inner mirror spherical radius is 190mm. Other than that, the same as in Example 1, the lenticular lens headlamp of the present invention was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com