Positive-pressure purification apparatus of high-temperature combustible gas

A purification device and gas technology, applied in the direction of gas dust removal, etc., can solve the problems of insufficient use of combustible gas sensible heat, large equipment footprint, high equipment investment costs, etc., to avoid equipment blockage and low-temperature sulfur dioxide corrosion, Less maintenance, lower operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

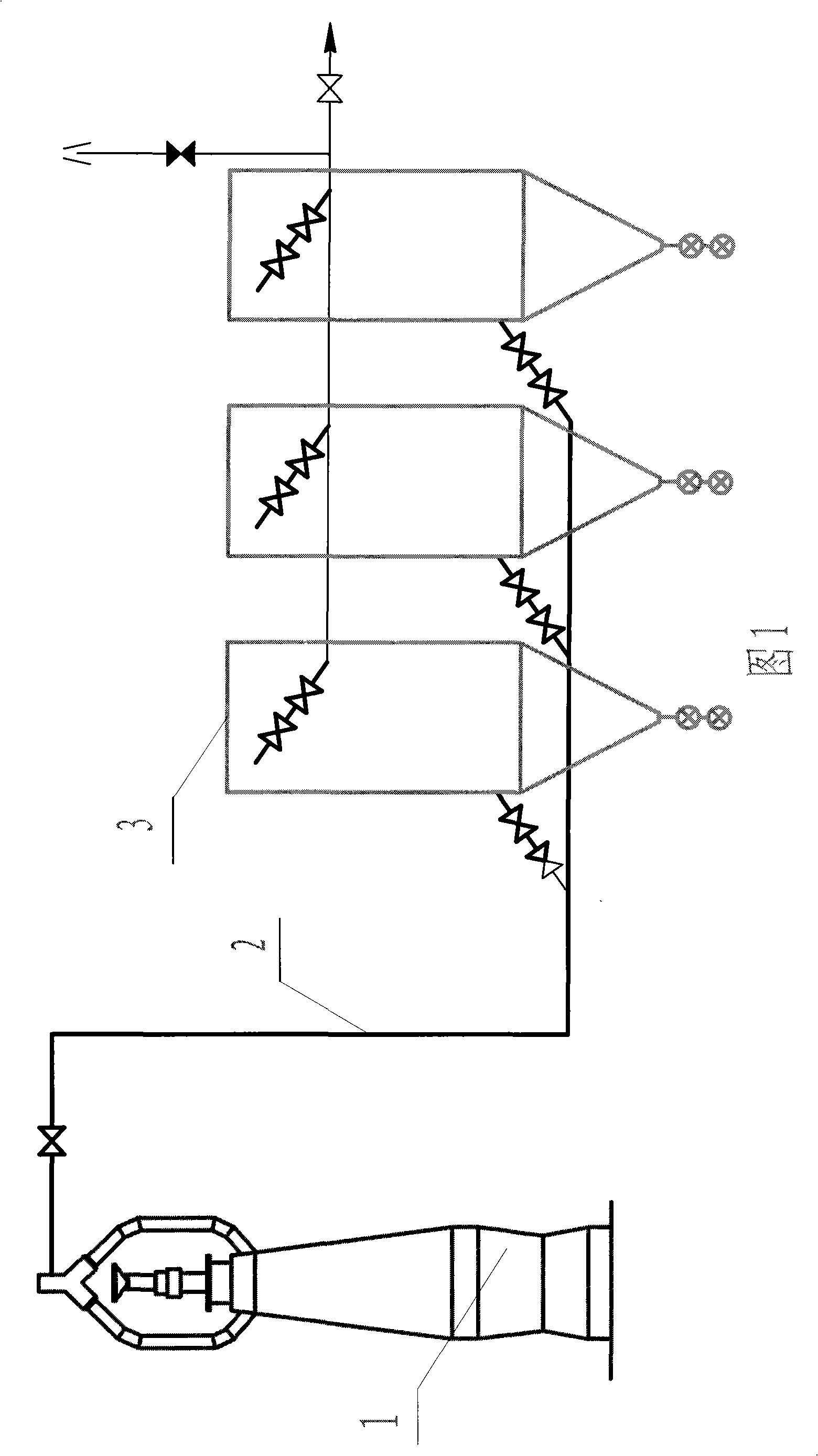

[0008] Below in conjunction with accompanying drawing, the present invention will be further described

[0009] A high-temperature combustible gas positive pressure purification device includes combustible gas generating equipment 1, and the combustible gas generating device is connected in parallel with at least two high-temperature dust collectors 3 through a gas pipeline 2.

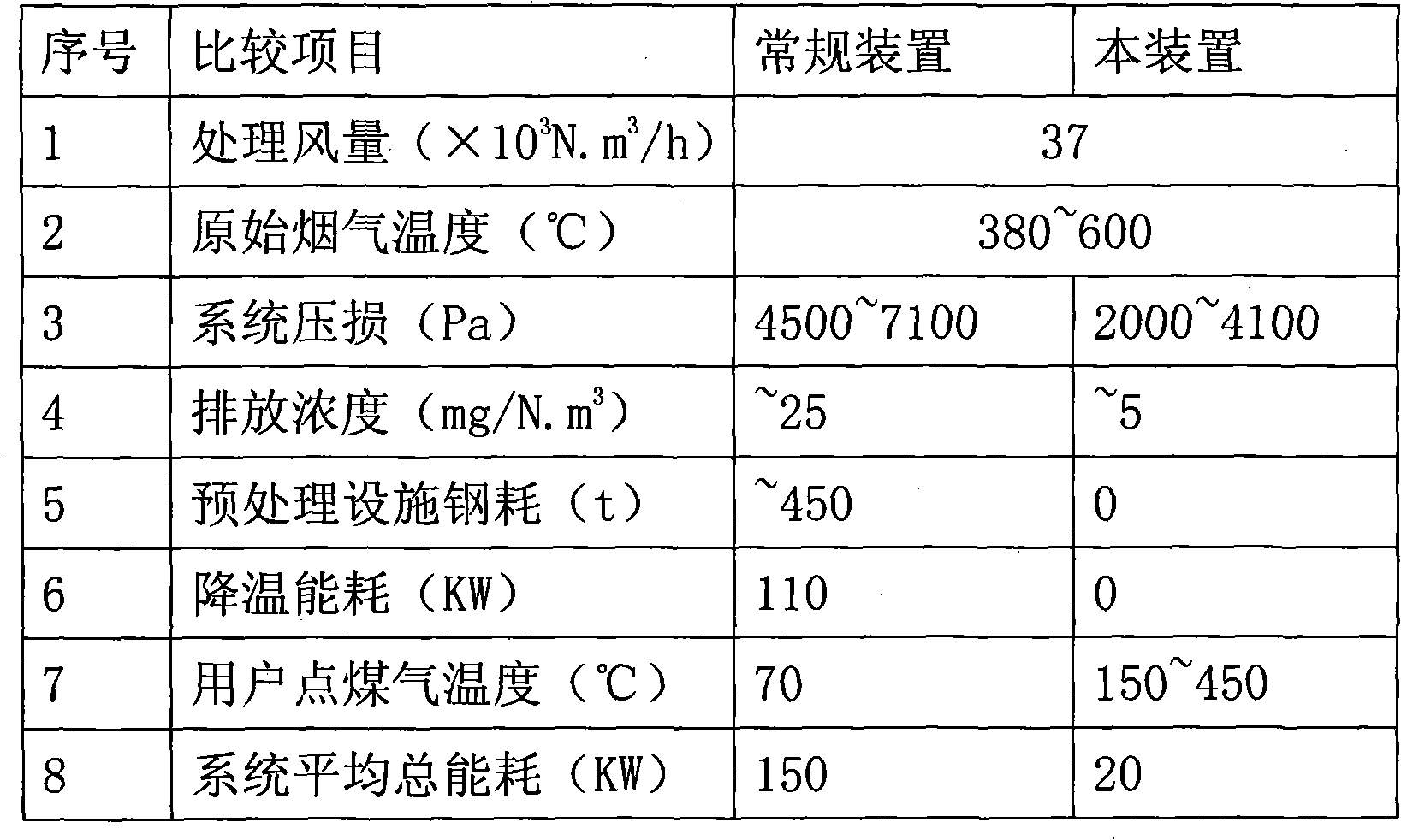

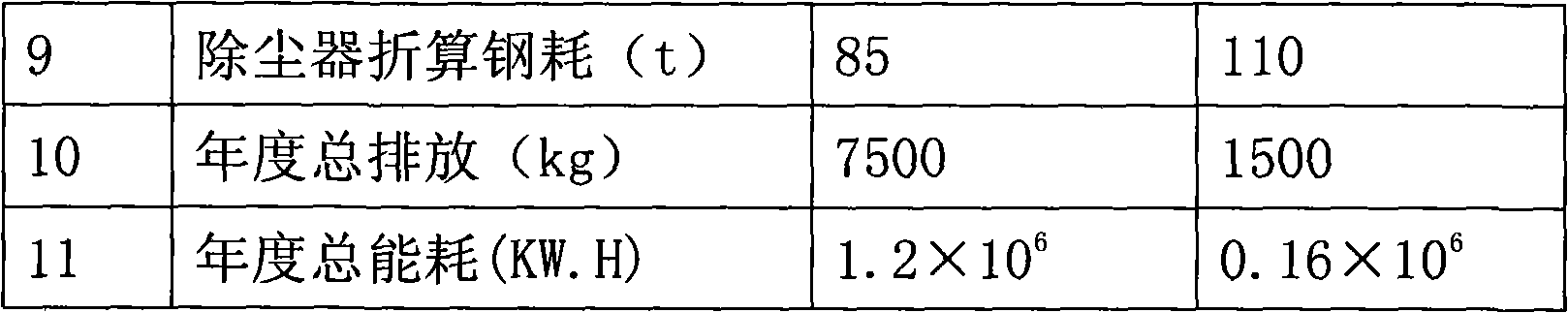

[0010] The high-temperature dust collector is equipped with a high-temperature-resistant filter element, which is made of a sintered structure similar to ceramics. It can generally withstand a long-term working temperature of about 600°C, and can withstand a high temperature of up to 1600°C after passing through, and can withstand the erosion of high-temperature large particles , so the high-temperature flue gas can be directly purified without any pretreatment. The dust concentration after purification is basically 2~8mg / N.m 3 , and the filtering wind speed is high, generally between 1~2m / min;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com