Sulfur hexafluoride gas insulating transformer

A technology of sulfur hexafluoride gas and insulating transformers, which is applied in the manufacture of inductors/transformers/magnets, transformers/inductor coils/windings/connections, electrical components, etc. There are many problems and the height of the transformer is high, so as to improve the short-circuit resistance, reduce the production cost and reduce the height.

Active Publication Date: 2008-10-29

BAODING TIANWEI BAOBIAN ELECTRICAL

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the high voltage of 110kV high-voltage SF6 gas-insulated transformers adopts the YN connection method, and is a graded insulation structure, that is, the insulation level of the high-voltage head end is 110kV, and the insulation level of the high-voltage neutral point is 60kV or 40kV. Its high-voltage insulation and high-voltage lines The coil structure adopts the following methods: 1. The high-voltage coil adopts the end-inlet structure, that is, the 110kV high-voltage head end is drawn from the upper and lower ends of the high-voltage coil. This structure will inevitably lead to local concentration of the electric field at the ends of the high-voltage and low-voltage coils. , in order to reduce the local concentration of the electric field at the end of the transformer coil, the transformer with this structure is equipped with electrostatic plates at the ends of the high-voltage and low-voltage coils. The transformer has high height, large volume, and high manufacturing cost.

2. The high-voltage coil adopts a full-entangled winding method. Although it can meet the impact voltage intensity of sulfur hexafluoride SF6 gas and effectively improve the impact voltage distribution of the high-voltage coil, for transformers with large capacity (20MVA and above), There are many coils connected in parallel, many welding heads, and winding is difficult, and the quality is not easy to guarantee, which is not conducive to improving the short-circuit resistance of the transformer

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

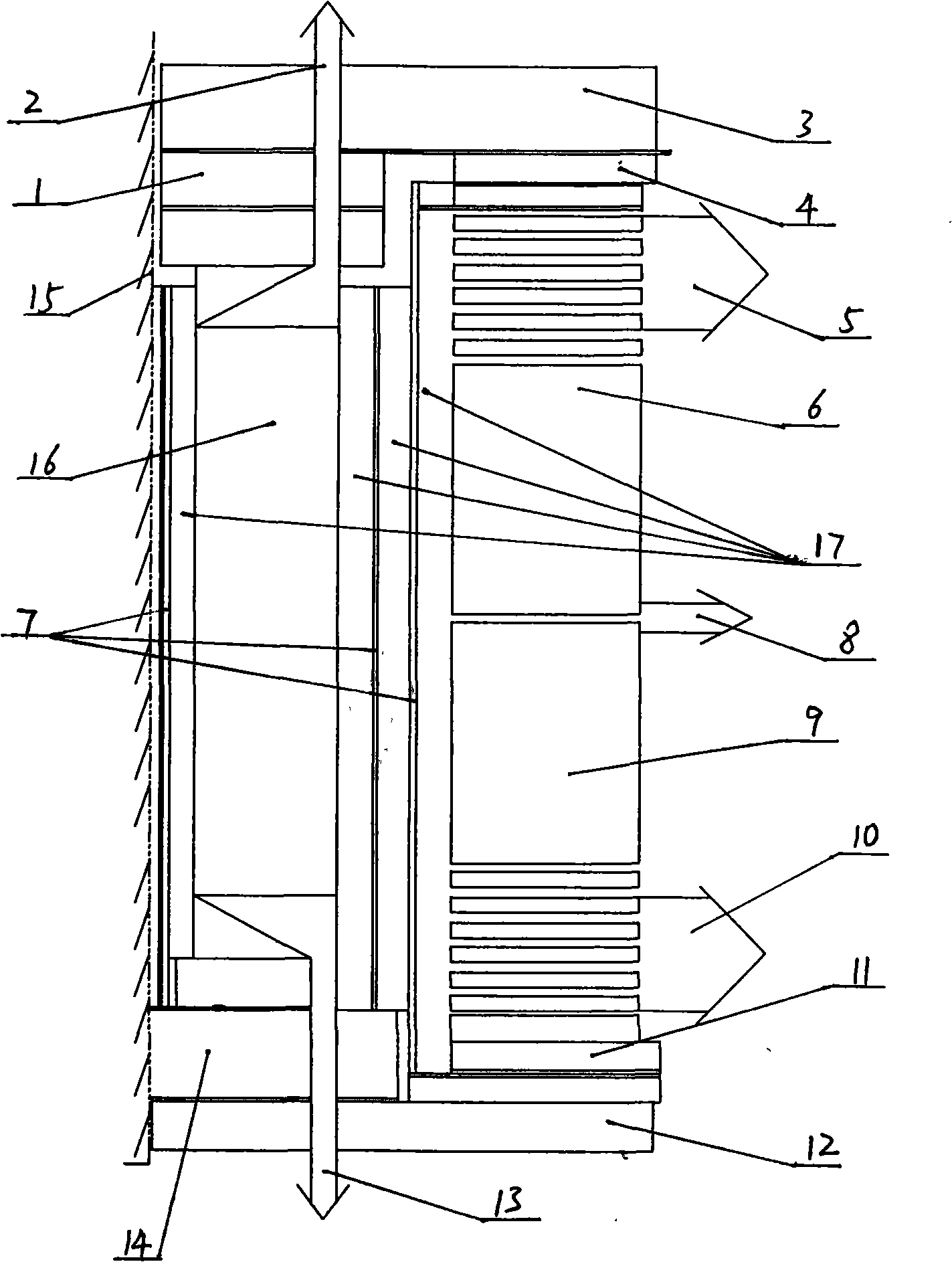

The invention discloses a sulfur hexafluoride gas insulating transformer which includes an iron core, a low voltage loop, a high voltage loop, the upper end insulator of the low voltage loop, the lower end insulator of the low voltage loop, the upper end insulator of the high voltage loop, the lower end insulator of the high voltage loop, the main insulating paper cylinder of the loop and the bar stay of the loop, a loop pressure pad and a splint for a core and winding assembly; the expansion lines of the beginning end and the tail end of the low voltage loop respectively cross the insulators of the upper and the lower ends, and the loop pressure pad and the splint for the core and winding assembly to lead out the core and winding assembly from the two ends of the core and winding assembly; the high voltage loop is divided into an upper path and a lower path in parallel; the high voltage loop is twisted by adopting an inner shielding-continuous mode; a plurality of winding coils at the starting end of 110KV of the high voltage loop adopt double-section screen structures; the expansion lines of the beginning ends of 110KV of the upper half path and the lower half path of the high voltage loop penetrate the core and winding assembly and are led out from the middle part; the expansion lines of the tail ends of the upper half path and the lower half path of the high voltage loop penetrate of the high voltage loop penetrate the insulators of the upper and the lower end parts of the high voltage loop, the loop pressure pad and the splint for the core and winding assembly and lead out the core and winding assembly from the two ends of the core and winding assembly. The localized concentration of the electric field at the end part of the loop of the transducer of the transformer is low; the anti-short circuit ability of the high voltage loop is high; the manufacture is easy; the materials are saved and the cost is low.

Description

Sulfur hexafluoride gas insulated transformer 1. Technical field The invention relates to a gas transformer, in particular to a 110kV gas-insulated transformer. 2. Background technology At present, the high voltage of 110kV high-voltage SF6 gas-insulated transformers adopts the YN connection method, and is a graded insulation structure, that is, the insulation level of the high-voltage head end is 110kV, and the insulation level of the high-voltage neutral point is 60kV or 40kV. Its high-voltage insulation and high-voltage lines The coil structure adopts the following methods: 1. The high-voltage coil adopts the end-inlet structure, that is, the 110kV high-voltage head end is drawn from the upper and lower ends of the high-voltage coil. This structure will inevitably lead to local concentration of the electric field at the ends of the high-voltage and low-voltage coils. , in order to reduce the local concentration of the electric field at the end of the transformer coil, e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01F27/28H01F41/02

Inventor 边庆凯谢毓城李敏王奎生李素雅

Owner BAODING TIANWEI BAOBIAN ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com