Nondestructive testing device for ferromagnetic slender component based on improved coil

A slender component and non-destructive testing technology, which is applied in the direction of measuring devices, material magnetic variables, and material analysis through electromagnetic means, can solve the problems of low signal-to-noise ratio of detection signals and complicated production of clam-shaped structure coils, etc., and achieve improvement The effect of signal-to-noise ratio, simplified winding, optimized installation position and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

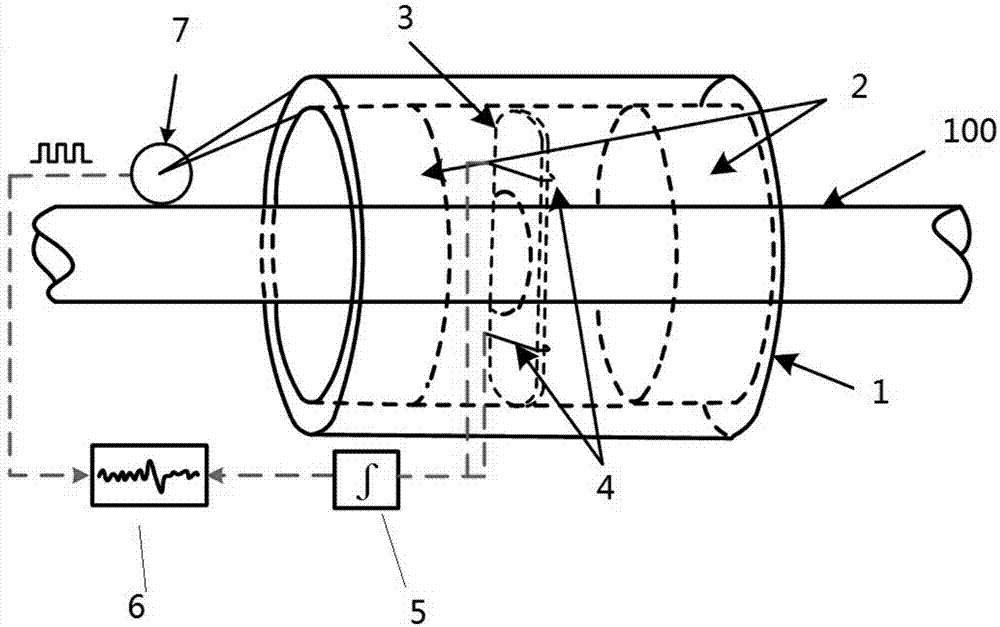

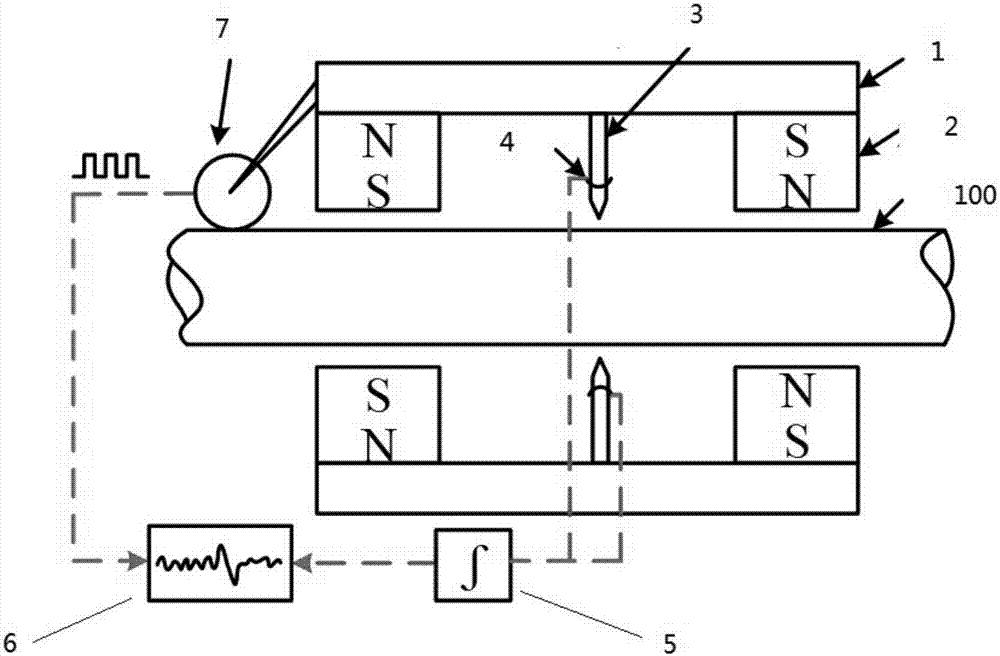

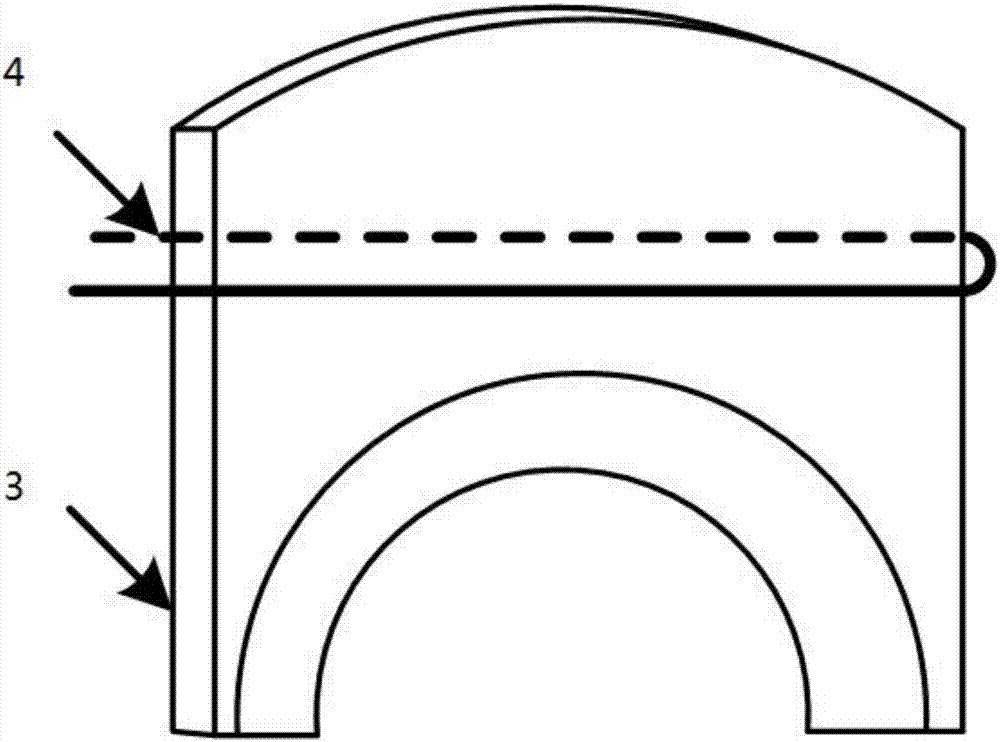

[0026] Such as Figure 1 to Figure 6 As shown, an improved coil-based non-destructive testing device for ferromagnetic elongated members includes two detection probes that enclose ferromagnetic elongated members 100 up and down and are arranged symmetrically. A yoke 1, a permanent magnet 2 and an iron core 3 are respectively arranged on the side, and the permanent magnet 2 has two and are arranged on the left and right ends of the yoke 1 respectively, and the iron core 3 is arranged on the yoke 1 and between the two permanent magnets 2, one end of the iron core 3 is provided with an arc-shaped protrusion, and the other end of the iron core 3 is provided with an arc-shaped groove, and the iron core 3 The left and right sides of the iron core 3 are respectively vertical planes, and an induction coil 4 is wound on the iron core 3 .

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com