Steel reinforced concrete fore shaft beam and method for supporting foundation pit

A technology of reinforced concrete and lock beams, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems of high cost, non-reusable lock beams, and large steel consumption of steel structure lock beams, and achieve easy recycling and high rigidity Large, the effect of increasing the support height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

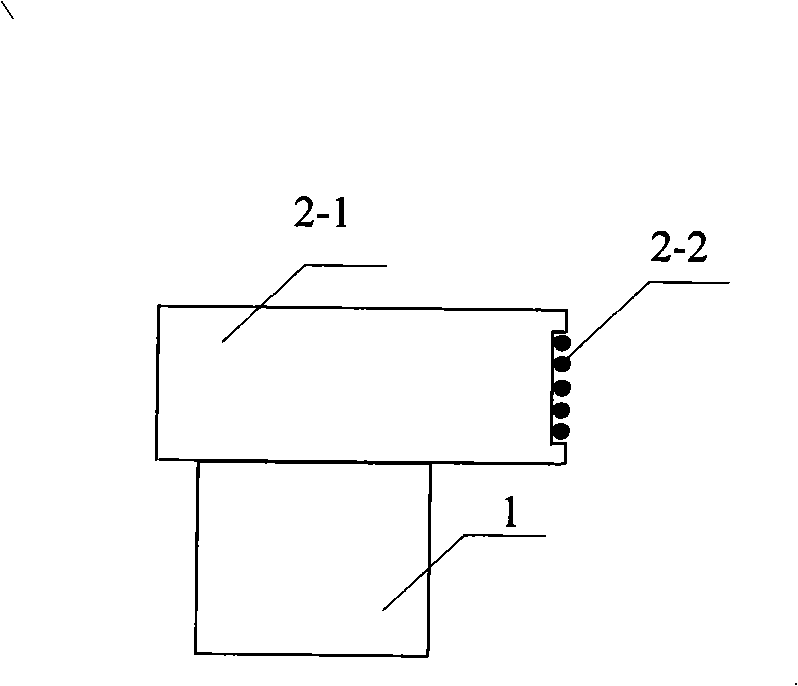

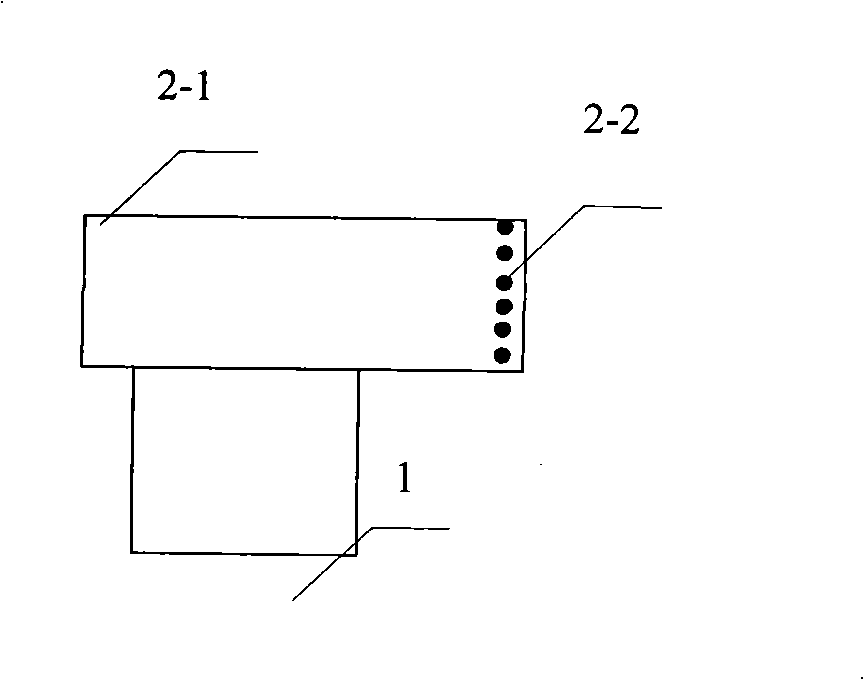

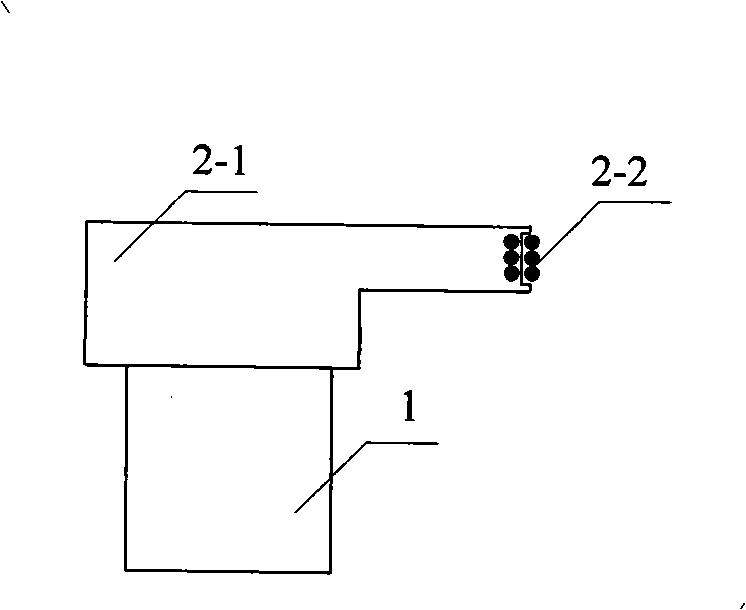

[0018] See attached Figure 1~6 , use concrete 2-1 and prestressed steel bars 2-2 to prepare reinforced concrete interlocking beams, and the lateral cross section of interlocking beams can be rectangular (see attached figure 1 , attached figure 2 And attached Figure 5 ), in order to save material, the lateral cross-section of the locking beam can also be T-shaped (see attached Figure 4 ) or L-shaped (see attached image 3 ) and other constant or variable cross-sections of various transformation shapes. The prestressed steel bars are longitudinally installed inside the side of the locking beam close to the foundation pit (see attached figure 2 ), can also be installed longitudinally on the surface of the locking beam near the foundation pit side (see attached figure 1 ), it can also be installed inside and on the surface of the side of the locking beam close to the foundation pit (see attached image 3 , attached Figure 4 , attached Figure 5 And attached Image 6...

Embodiment 2

[0020] The method for applying the reinforced concrete locking beam of the present invention to support the foundation pit is specifically implemented as follows: Excavate the foundation groove, construct the guide wall in the foundation groove according to the design requirements; construct the support structure 1, the support structure can be row piles or continuous Wall or steel structure supporting piles; after the function of the guide wall is completed, remove the guide wall; install the prestressed reinforced concrete lock beam 2 on the upper end of the support structure 1, and specifically adopt the post-tensioning method to construct the lock beam: install the formwork first, Then locate and install the prestressed steel bars 2-2 with sleeves, and then pour concrete 2-1. After the concrete reaches the curing age, stretch the prestressed steel bars in batches and anchor them with anchors 2-3. The cantilever support structure is connected as a whole with the lock beam, a...

example 2

[0021] Example 2: Reference figure 2 , Figure 5 with Figure 7 , The foundation pit support method of this example is the same as that of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com