Erecting machine of bridge span for road and railway

A bridge erecting machine, highway and railway technology, which is used in the erection/assembly of bridges, bridges, bridge construction, etc. The requirements that must be guaranteed, to achieve the effect of shortening the transfer time, simple assembly, and large workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention are further described below in conjunction with the accompanying drawings, but they are not intended to limit the present invention.

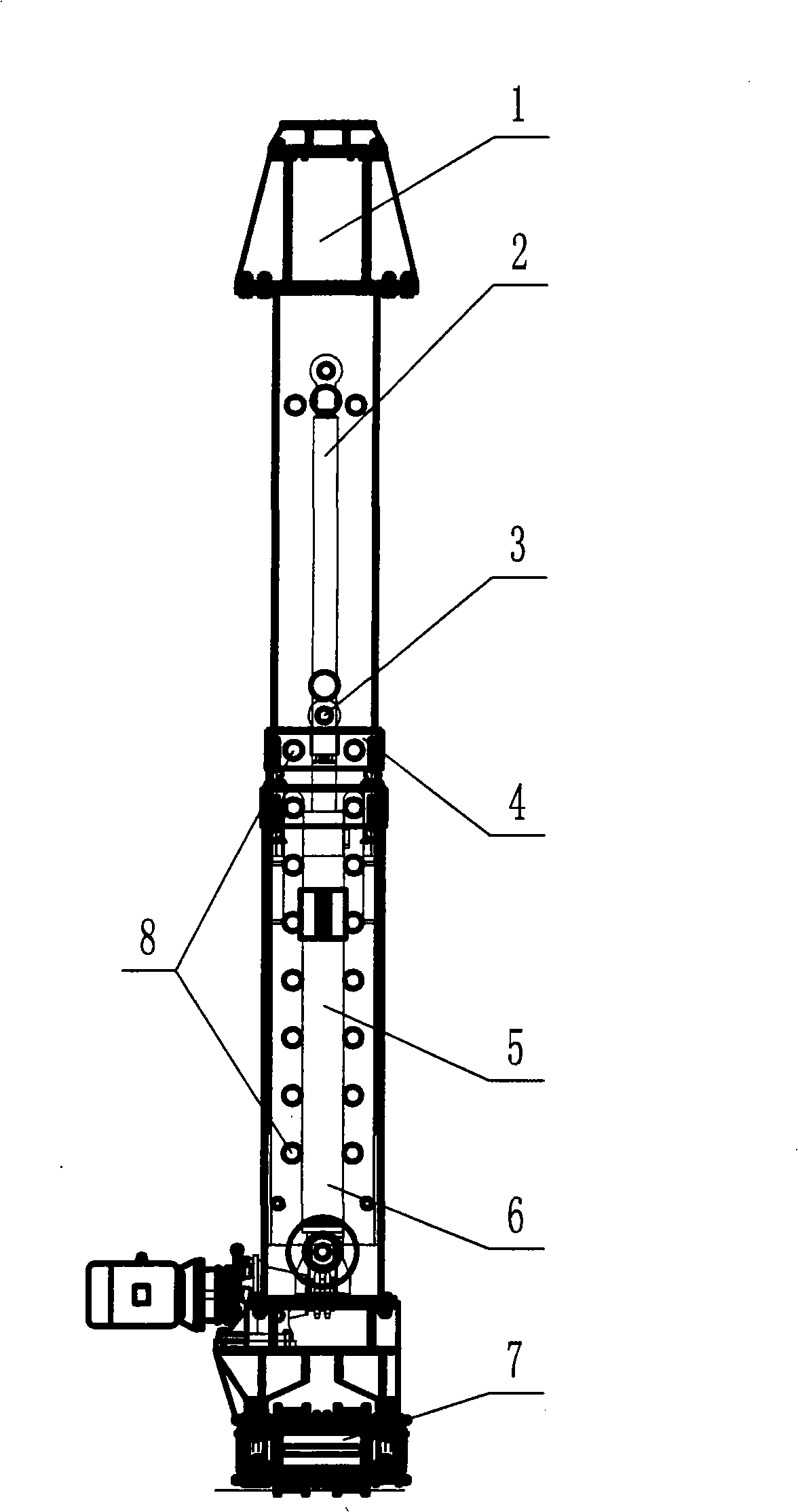

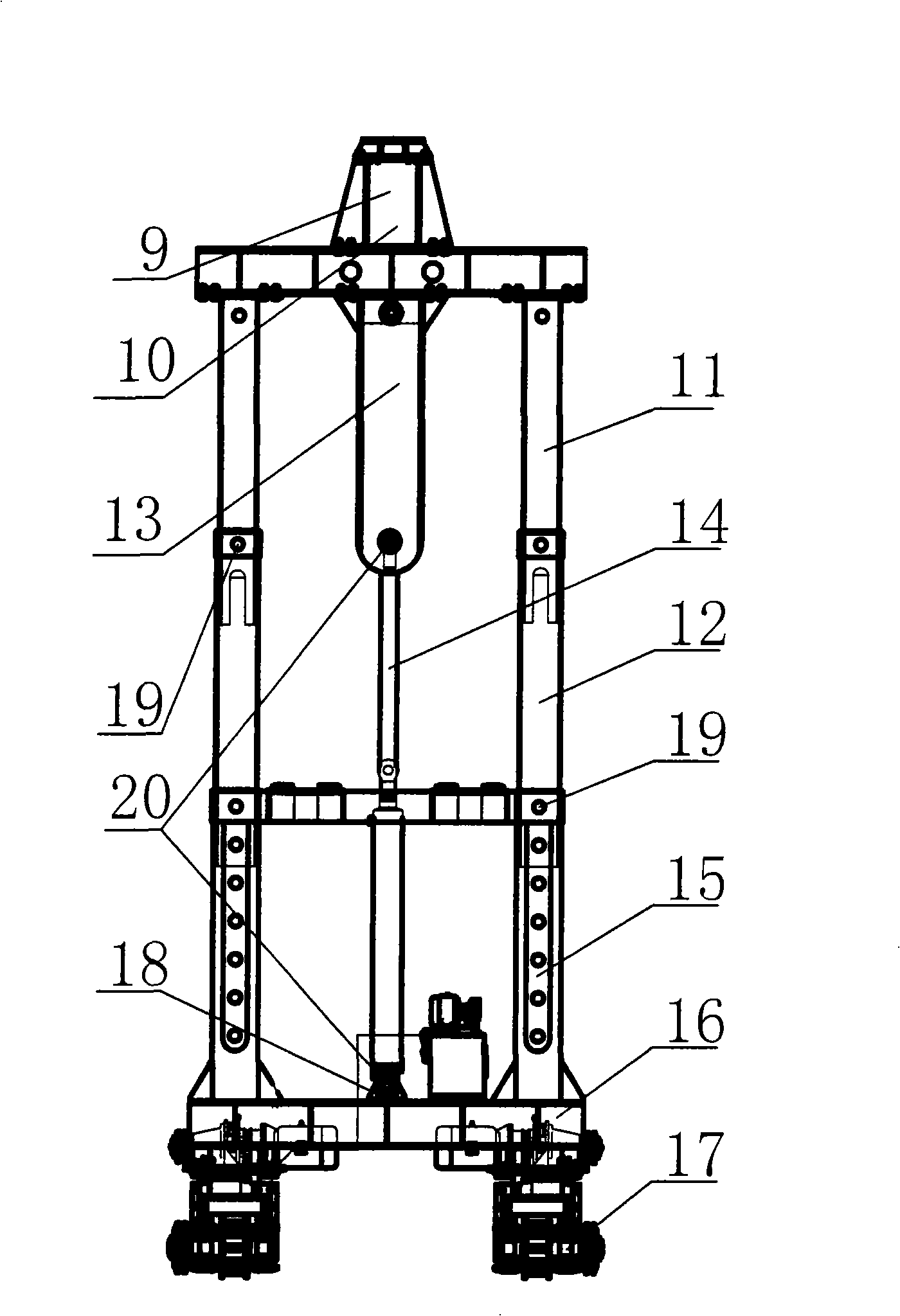

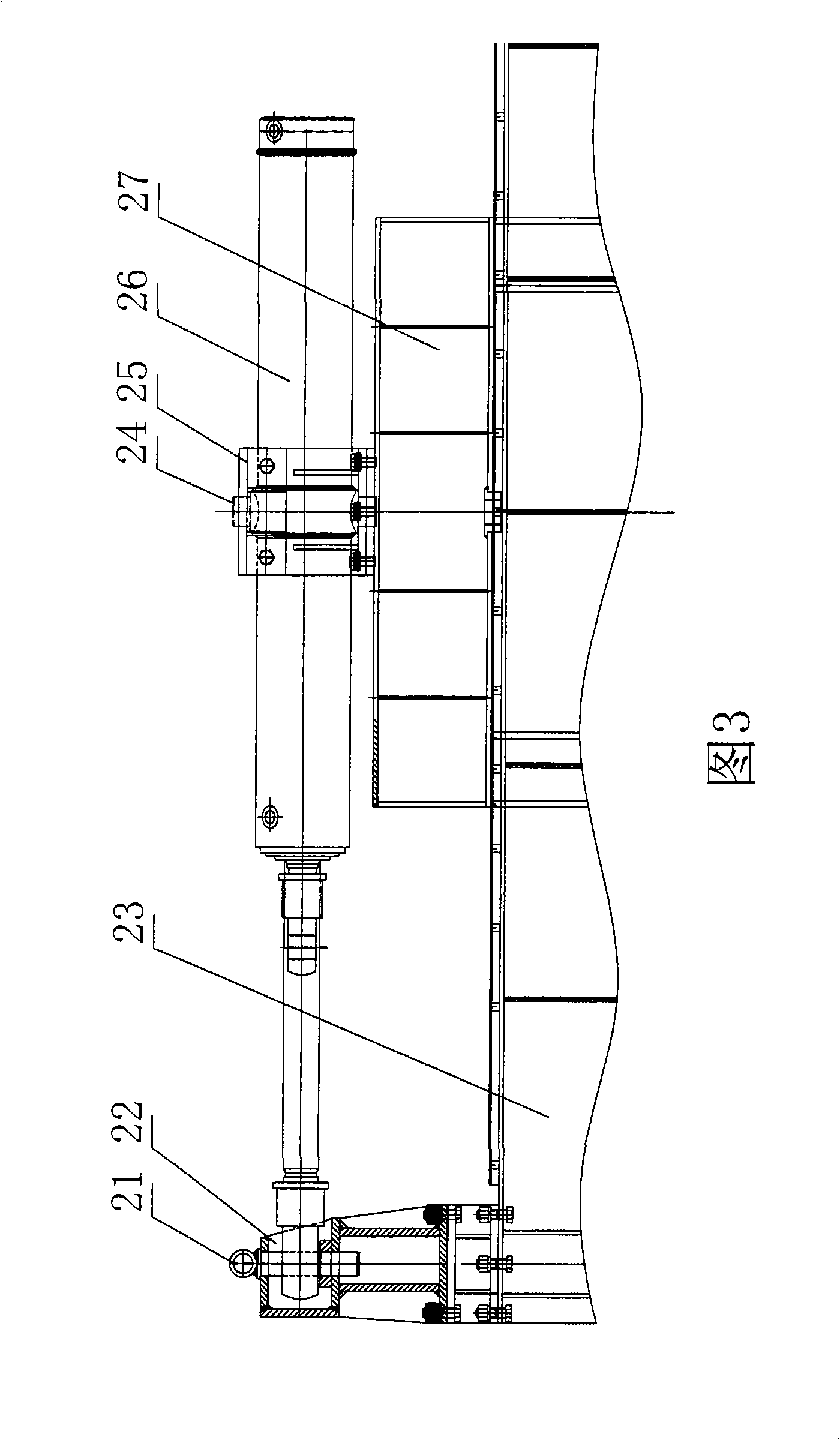

[0039] The overall structure of this embodiment is as shown in the figure, which includes booms I and II, crane beam trolleys on the boom, pillars, and hydraulic traverse mechanism; it also includes:

[0040] A. The first and third columns of the pillars include the upper beam 1, the primary guide column 2, the secondary guide column 4, the jacking cylinder 5, the guide bushing 6, and the walking beam 7; the upper beam 1 and the primary guides on both sides The top of the column 2 is fixedly connected; the lower end of the primary guide column 2 is inserted and fixed in the secondary guide column 4; the lower end of the secondary guide column 4 is inserted and fixed in the guide sleeve 6; the lower end of the guide sleeve 6 is fixedly connected to the walking beam 7; The movable end of the lifting cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com