Plasma film coating apparatus for particle surface modification

A particle surface, coating device technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of poor uniformity of polymer film, unsuitable for surface coating of fine particles, etc., to improve anti-thrombosis, The effect of improving electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

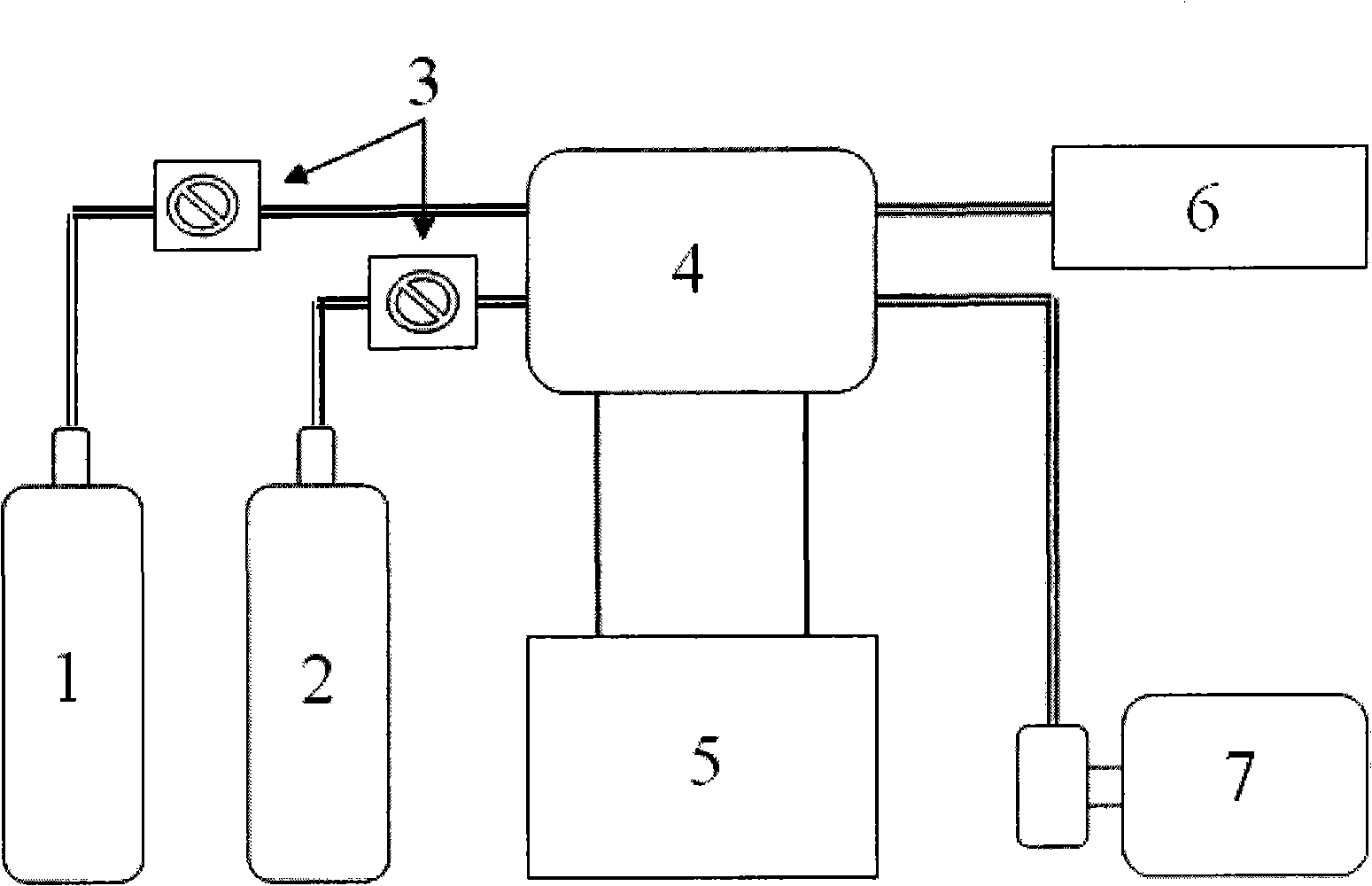

[0034] like figure 1 As shown, the device of this embodiment is mainly composed of a reaction chamber 4, a radio frequency power supply 5, a monomer vapor generating bottle 1, an argon gas bottle 2, a flow controller 3, a vacuum gauge 6 and a vacuum pump 7; the monomer vapor generating bottle 1. The argon gas bottle 2 and the vacuum pump 7 are respectively connected to the reaction chamber 4 through pipelines, and the pipelines connecting the monomer vapor generating bottle 1 and the argon gas bottle 2 to the reaction chamber 4 are respectively provided with a flow controller 3, and the radio frequency The power supply 5 is connected with a radio frequency discharge coil, and the radio frequency discharge coil is wound on the outer wall of the container of the reaction chamber 4 .

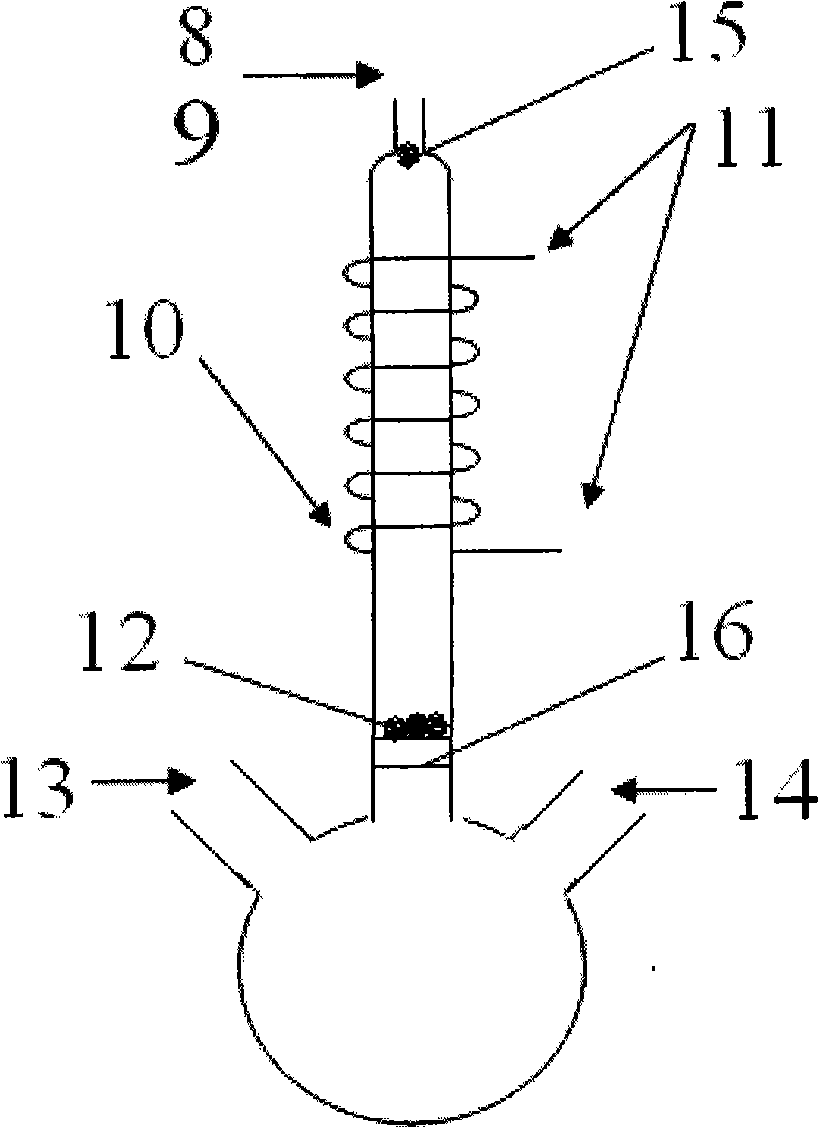

[0035] The reaction chamber 4 of this embodiment is a plasma polymerization reaction chamber 4 adopting the scheme of particle self-dispersing small glass tubes. like figure 2 As shown, the main...

Embodiment 2

[0042] The reaction chamber 4 of this embodiment adopts the scheme of magnetically stirring the upright cylindrical glass tube, and the rest of the parts except the reaction chamber 4 and the connection relationship between each part are consistent with the embodiment 1, and will not be repeated. The structure of the reaction chamber 4 in this embodiment will be described below.

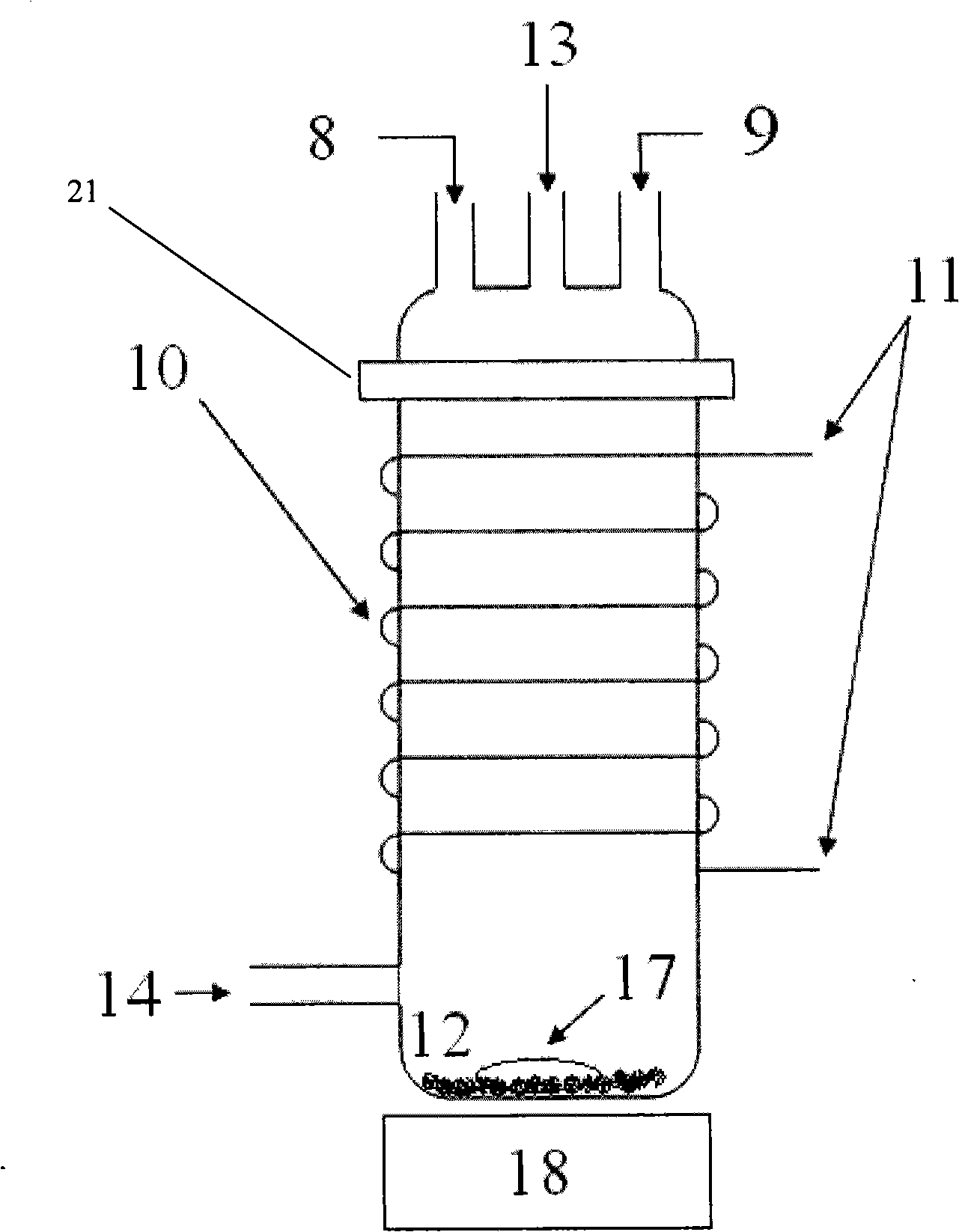

[0043] like image 3 As shown, the reaction chamber 4 of this embodiment is an upright glass tube with a diameter of 100 mm and a length of 600 mm, and the sample is placed at the bottom of the glass tube. A magnetic stirrer is set just below the glass tube. There is a magnetic stirring blade 17 inside the glass tube, and the magnetic stirring blade 17 is installed at the bottom of the glass tube. The monomer vapor inlet 14 is located on the side wall near the bottom of the glass tube, and the top of the glass tube has an argon gas inlet 13 , a vacuum pump port 8 and a vacuum gauge port 9 . The radi...

Embodiment 3

[0048] The reaction chamber 4 of this embodiment adopts the motor-stirred horizontal glass tube scheme, and the rest of the parts except the reaction chamber 4 and the connection relationship between each part are consistent with the embodiment 1, and will not be repeated. The structure of the reaction chamber 4 in this embodiment will be described below.

[0049] like Figure 4 As shown, the reaction chamber 4 in this embodiment is a horizontal glass tube with a diameter of 15 mm and a length of 1000 mm, and the sample particles 12 are placed on the inner wall of the lower side of the glass tube. A horizontal rotating shaft is installed in the glass tube, and the stirring blade is installed on the horizontal rotating shaft. The stirring motor drives the stirring blades to rotate through the horizontal rotating shaft. The stirring motor, the horizontal shaft and the stirring blades are all sealed in the glass tube. Argon inlet 13 , monomer vapor inlet 14 , vacuum gauge port...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com