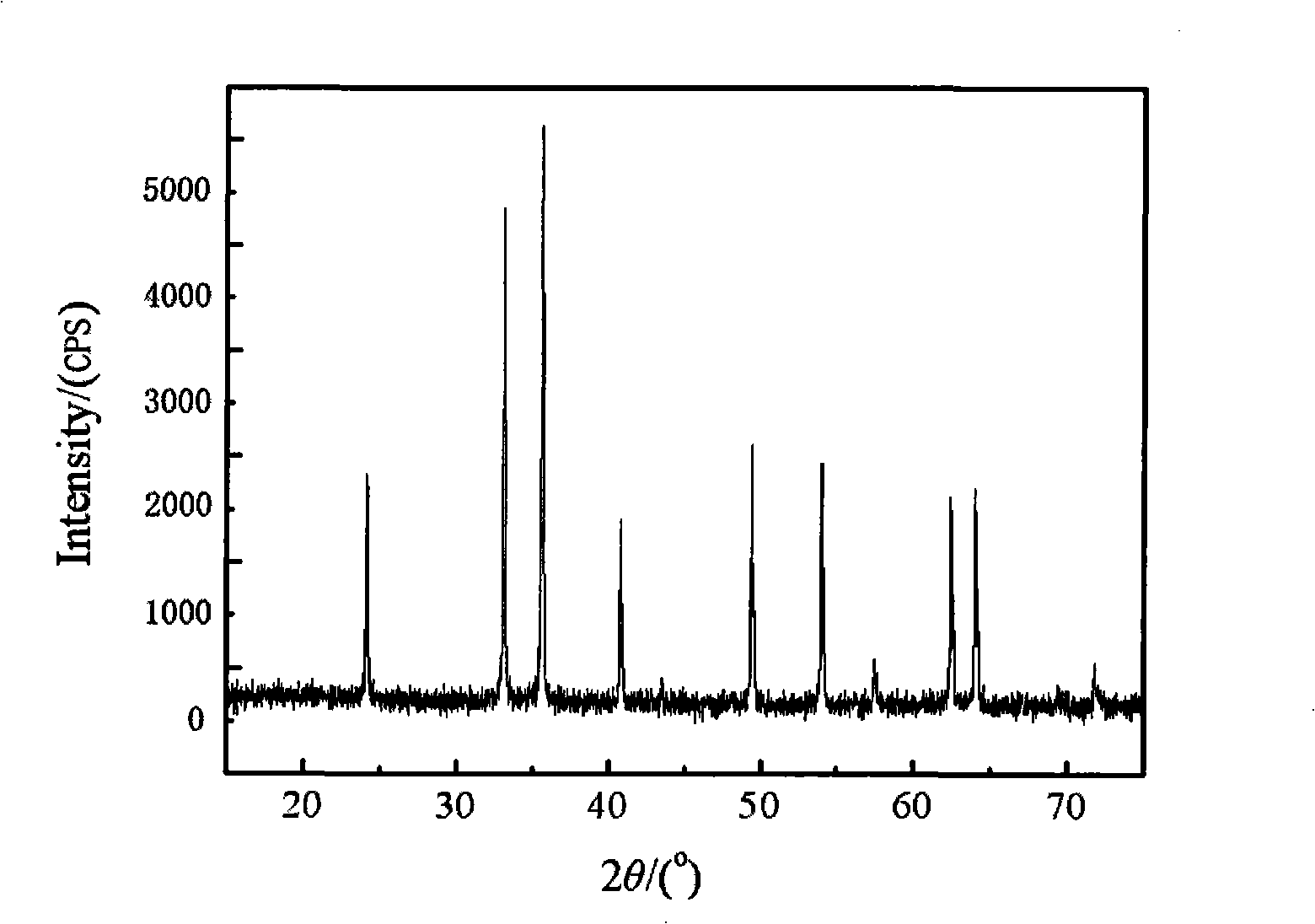

Method for preparing spindle shaped alpha-Fe2O3 powder

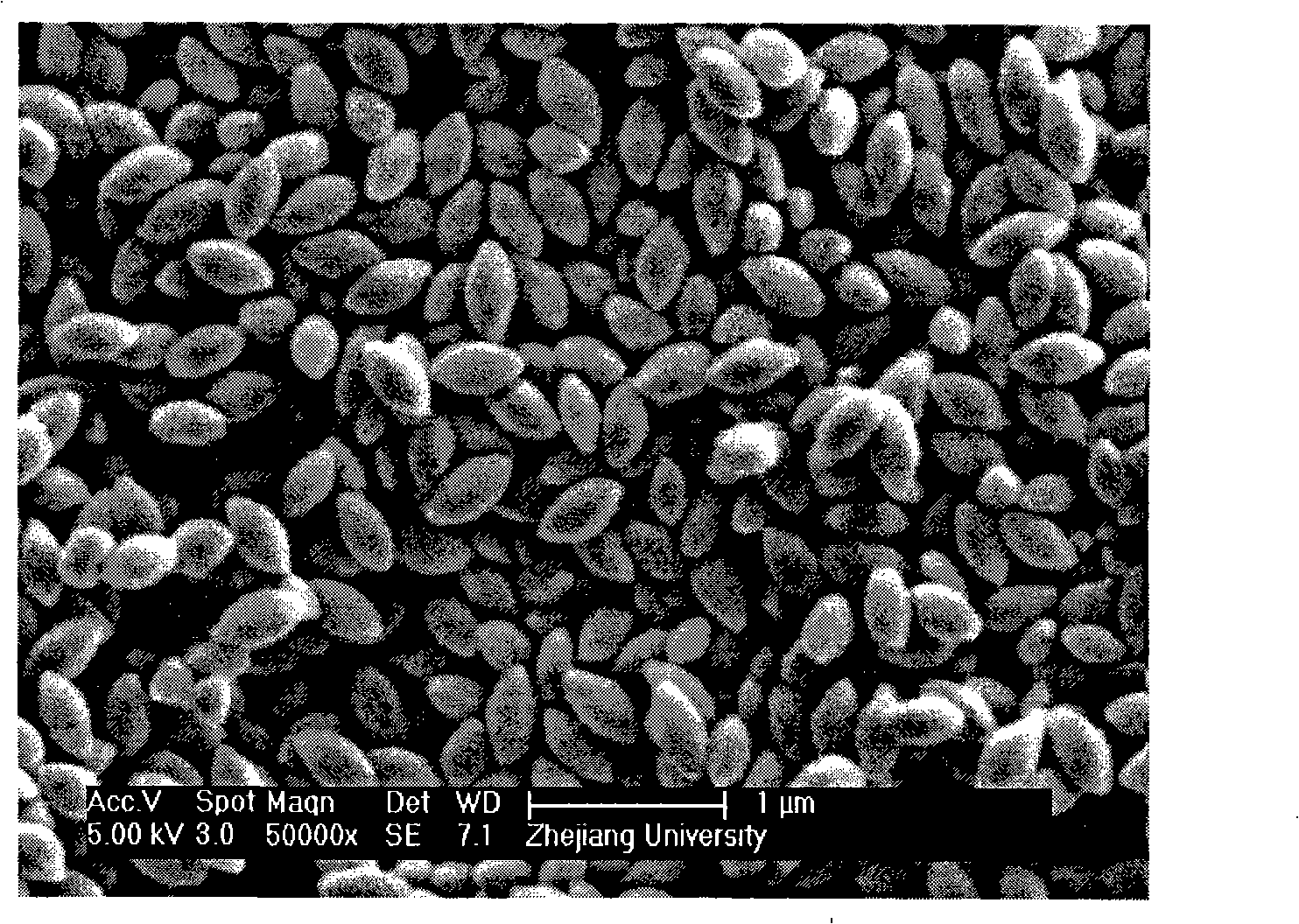

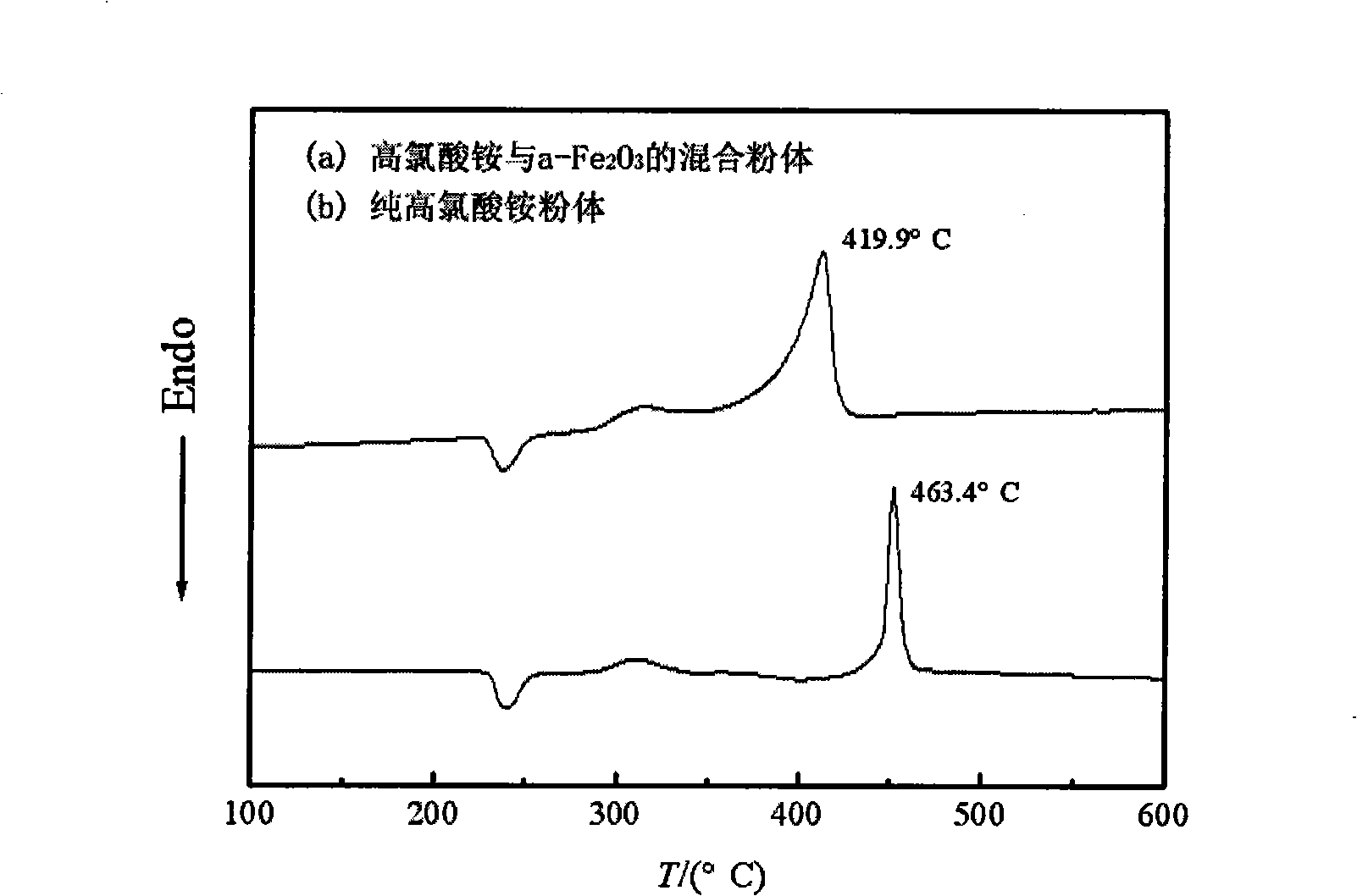

A nano-powder, spindle-shaped technology is applied in the field of preparation of spindle-shaped α-Fe2O3 nano-powder, which can solve the problem of uneven size of nano-powder ellipsoid particles, and achieve stable product quality, easy control, and excellent catalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Water / Solvothermal Synthesis of Spindle α-Fe 2 o 3 Nano powder, the particle length is 400 nanometers, and the maximum diameter is 200 nanometers.

[0022] Synthesize spindle-shaped α-Fe according to the following process steps 2 o 3 Nano powder.

[0023] 1) Measure ethylene glycol and deionized water at a volume ratio of 20:20, respectively, and stir and mix them for 30 minutes to obtain a mixed solvent with a volume ratio of ethylene glycol and water of 20:20.

[0024] 2) Weigh 0.005mol (2.05g) iron nitrate (Fe(NO 3 ) 3 9H 2 O) it is dissolved in the mixed solvent of ethylene glycol and water prepared in front of 20ml, and the iron nitrate liquid concentration that is formed is adjusted to be: 0.25mol / L (mole per liter).

[0025] 3) According to the molar ratio of ferric nitrate and potassium hydroxide as 1:3, measure and weigh potassium hydroxide (KOH), that is, weigh 0.015mol (1.03g) KOH, dissolve it in 20ml of ethylene glycol and water prepared earlier In t...

Embodiment 2

[0031] Water / Solvothermal Synthesis of Spindle α-Fe 2 o 3 Nano powder, the spindle particle length is 200 nanometers, the maximum diameter is 100 nanometers, and the aspect ratio is 2:1.

[0032]Concrete processing step is identical with example 1, and difference is: the volume ratio of ethylene glycol and water in the mixed solvent of preparation in step 1) is: 22: 18; Step 2) takes by weighing 0.001875mol ferric nitrate, and the ferric nitrate of preparation The concentration of the solution is: 0.1mol / L, correspondingly weigh 0.005625mol potassium hydroxide in step 3), and the concentration of the prepared potassium hydroxide solution is: 0.3mol / L; the reaction precursor is suspended in the final reaction kettle in step 4) The liquid accounts for 3 / 4 of the volume of the reactor, and the Fe in the suspension 3+ The molar volume fraction of ions and KOH is: 0.15mol / L. Then stir for 5 minutes. In step 5), the heat treatment temperature is 160° C., and the temperature is k...

Embodiment 3

[0034] Water / solvothermal synthesis of α-Fe with hexagonal disc-like particles 2 o 3 The nano powder has a particle length of 500 nanometers, a maximum diameter of 250 nanometers, and an aspect ratio of 2:1.

[0035] Concrete process step is identical with example 1, and difference is: the volume ratio of ethylene glycol and water in the mixed solvent of preparation in step 1) is: 14: 26; Step 2) takes by weighing 0.00833mol ferric nitrate, and the ferric nitrate of preparation The concentration of the solution is: 0.5mol / L, correspondingly weigh 0.025mol potassium hydroxide in step 3), and the concentration of the prepared potassium hydroxide solution is: 1.5mol / L; the reaction precursor is suspended in the final reactor in step 4) The liquid accounts for 2 / 3 of the volume of the reactor, and the molar volume fraction of Fe3+ ions and KOH in the suspension is: 0.75mol / L. Then stir for 60 minutes. In step 5), the heat treatment temperature is 240°C. The synthesized α-Fe 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com