Preformed liner adhered to a pipe with an adhesive

A pre-forming, adhesive technology used in synthetic resin layered products, pipe elements, tubular articles, etc., to solve problems such as lining bends, narrowing of oil flow paths, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

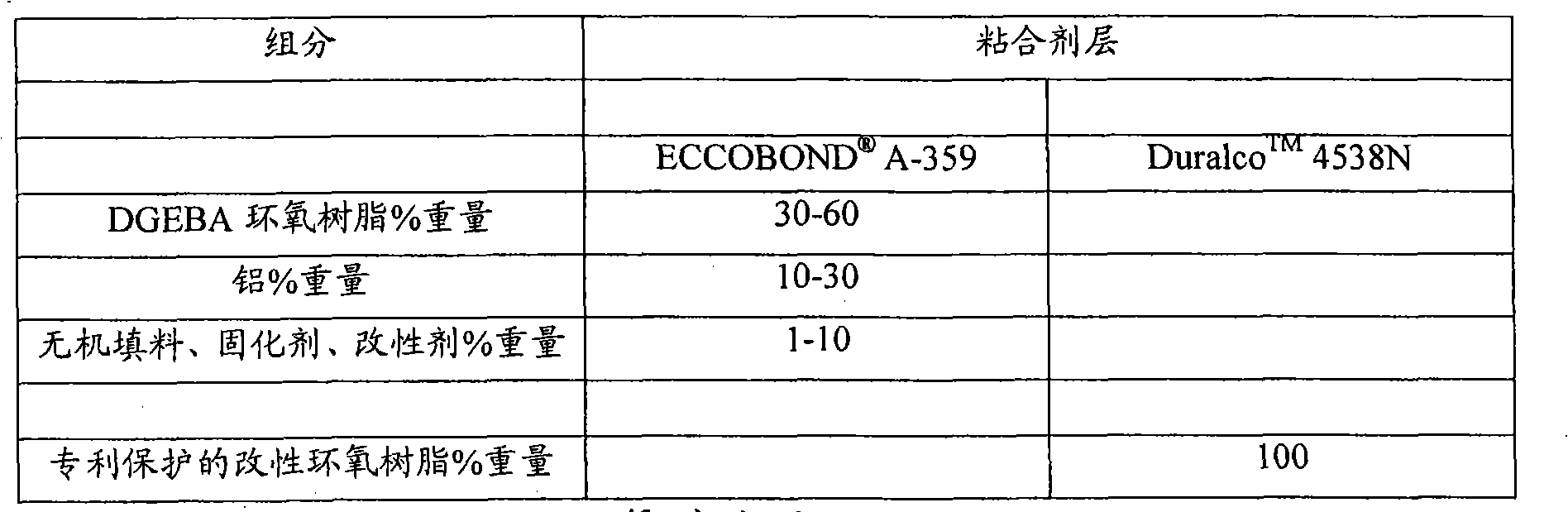

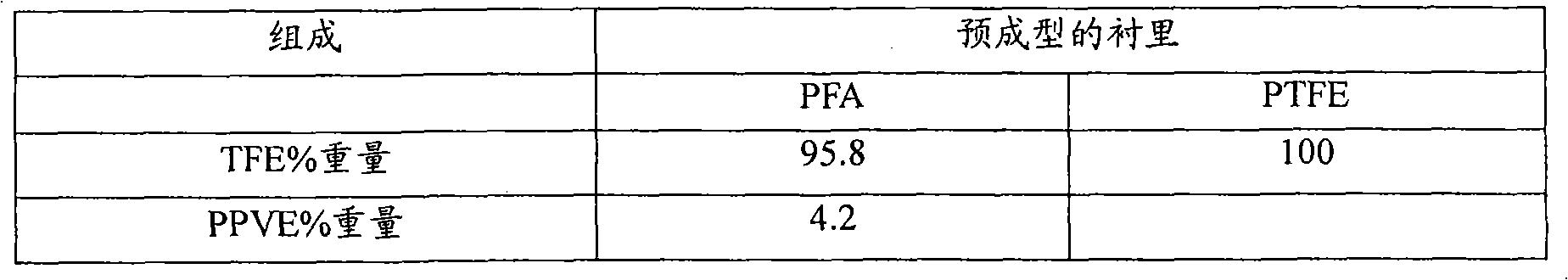

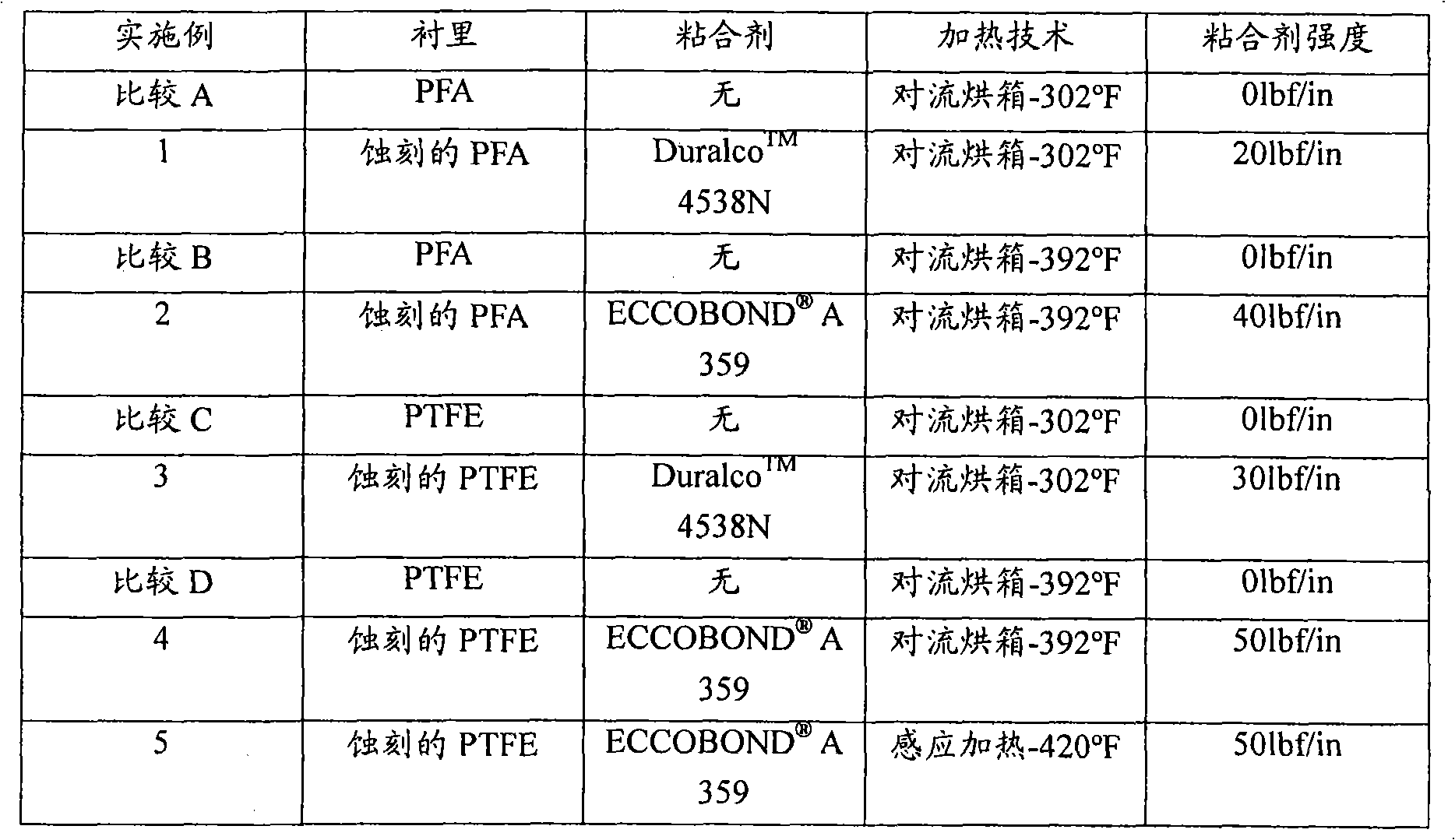

[0073] Example 1 - Contains Duralco TM 4538N Epoxy PFA

[0074] The preformed PFA liner was chemically etched approximately 1300 microns (50 mils) thick using a sodium in ammonia solution. Subsequent use of Duralco TM A 4538N adhesive coat "coats" the outside of the liner. Slide the epoxy coated liner into the blast tube with a snug "slip fit". Place the lined tube in a standard convection oven preheated to 302°F (150°C). When the sample reached the target temperature of 302°F, the sample was left in the oven for 60 minutes. After removing the sample from the oven and allowing it to cool, the sample was cut into strips and the adhesion strength of the liner to the pipe wall was 20 lbf / in.

Embodiment 2

[0077] Example 2 - Contains ECCOBOND A 359 Epoxy PFA

[0078] The preformed PFA liner was chemically etched approximately 1300 microns (50 mils) thick using a sodium in ammonia solution. Subsequent use of ECCOBOND A 359 adhesive coat "coats" the outside of the liner. Slip the epoxy coated liner into the sandblasted tube with a snug "slip fit". Place the lined tube in a standard convection oven preheated to 392°F (200°C). When the sample reached the target temperature of 392°F, the sample was left in the oven for 15 minutes. After removing the sample from the oven and allowing it to cool, the sample was cut into strips and the adhesion strength of the liner to the pipe wall was 40 lbf / in.

Embodiment 3

[0081] Example 3 - Contains Duralco TM 4538N PTFE

[0082] The preformed PTFE liner was chemically etched approximately 3900 microns (150 mils) thick using a solution of sodium in liquid ammonia. Subsequent use of Duralco TM A 4538N adhesive coat "coats" the outside of the liner. Slip the epoxy coated liner into the sandblasted tube with a snug "slip fit". Place the lined tube in a standard convection oven preheated to 302°F (150°C). When the sample reached the target temperature of 302°F, the sample was left in the oven for 60 minutes. After removing the sample from the oven and allowing it to cool, the sample was cut into strips and the adhesion strength of the liner to the pipe wall was 30 lbf / in.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com