Fiber reinforced inorganic doped proton exchange film containing fluorine

A proton exchange membrane and fiber-reinforced technology, applied in the field of functional polymer composite materials, can solve problems such as time-consuming and non-continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the fiber-reinforced inorganic material doped proton exchange membrane of the present invention comprises the following steps:

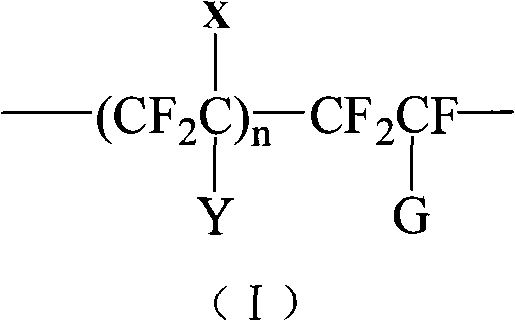

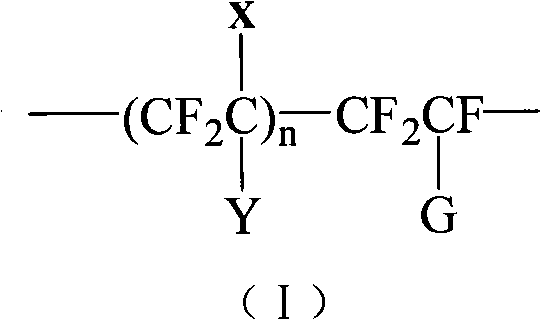

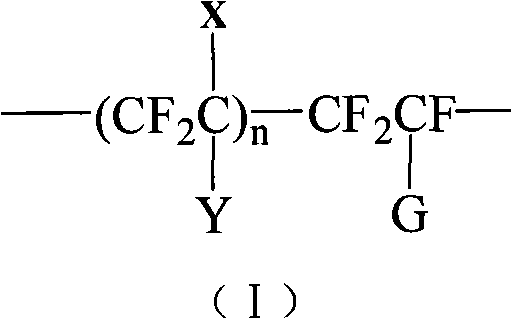

[0052] (1) dissolving the fluorine-containing sulfonic acid resin shown in general formula (I) with a polar solvent to form a fluorine-containing sulfonic acid resin solution;

[0053] (2) dispersing the inorganic matter in the fluorine-containing sulfonic acid resin solution prepared in step (1);

[0054] (3) Disperse the fibers in the polar solvent used in step (1), and mix them by ultrasonic or high-speed stirring to obtain a fiber dispersion;

[0055](4) Mix the fiber dispersion prepared in step (3) with the solution in step (2) to form a film by casting, casting, screen printing, spraying or dipping, and heat the film at 50-300°C, preferably 80-200° C., more preferably 120-190° C., heat treatment for 0.5-600 minutes, and peeled off to obtain a fiber-reinforced inorganic substance-doped fluorine-containing proton...

Embodiment 1

[0060] In general formula I, n=13, m=2, X=F, Y=F perfluorosulfonic acid resin was dissolved in N-methylpyrrolidone to prepare a solution with a solid content of 35%. Add 0.007μm ZrO 2 powder. Quartz fiber (ZrO) with a diameter of 0.01 μm and a length of 0.08 μm 2 The content is 0.5%, and the quartz fiber is 5%) dispersed in N-methylpyrrolidone, adding the dispersant sodium polyphosphate and vigorously stirring to disperse the fiber into the solvent. Solvent containing fibers and resin and ZrO 2 The powder dispersions were mixed, and heat-treated at 180° C. for 10 minutes by solution casting to prepare a fiber-reinforced inorganic-doped perfluorosulfonic acid proton exchange membrane with a thickness of 25 μm. Tensile strength: 24MPa, conductance: 133mS / cm.

Embodiment 2

[0062] In general formula I, n=7, m=3, X=H, Y=H perfluorosulfonic acid resin was dissolved in methyl formamide to prepare a solution with a solid content of 33%. Add 0.04μm Zr 3 (PO 4 ) 4 powder. Aluminum silicate fibers (Zr 3 (PO 4 ) 4 The content is 3%, the aluminum silicate fiber is 7%) dispersed in methyl formamide, and the dispersant potassium polyphosphate is added to vigorously stir to disperse the fiber into the solvent. Solvent containing fibers and resin and Zr 3 (PO 4 ) 4 The powder dispersions were mixed, and heat-treated at 160° C. for 30 minutes by solution casting to prepare a fiber-reinforced inorganic-doped perfluorosulfonic acid proton exchange membrane with a thickness of 38 μm. Tensile strength: 24MPa, conductance: 135mS / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com