High-voltage cable trouble point checking method and its device

A technology of high-voltage cables and detection methods, applied in fault locations, information technology support systems, etc., can solve problems such as poor stability, and achieve the effects of low cost and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

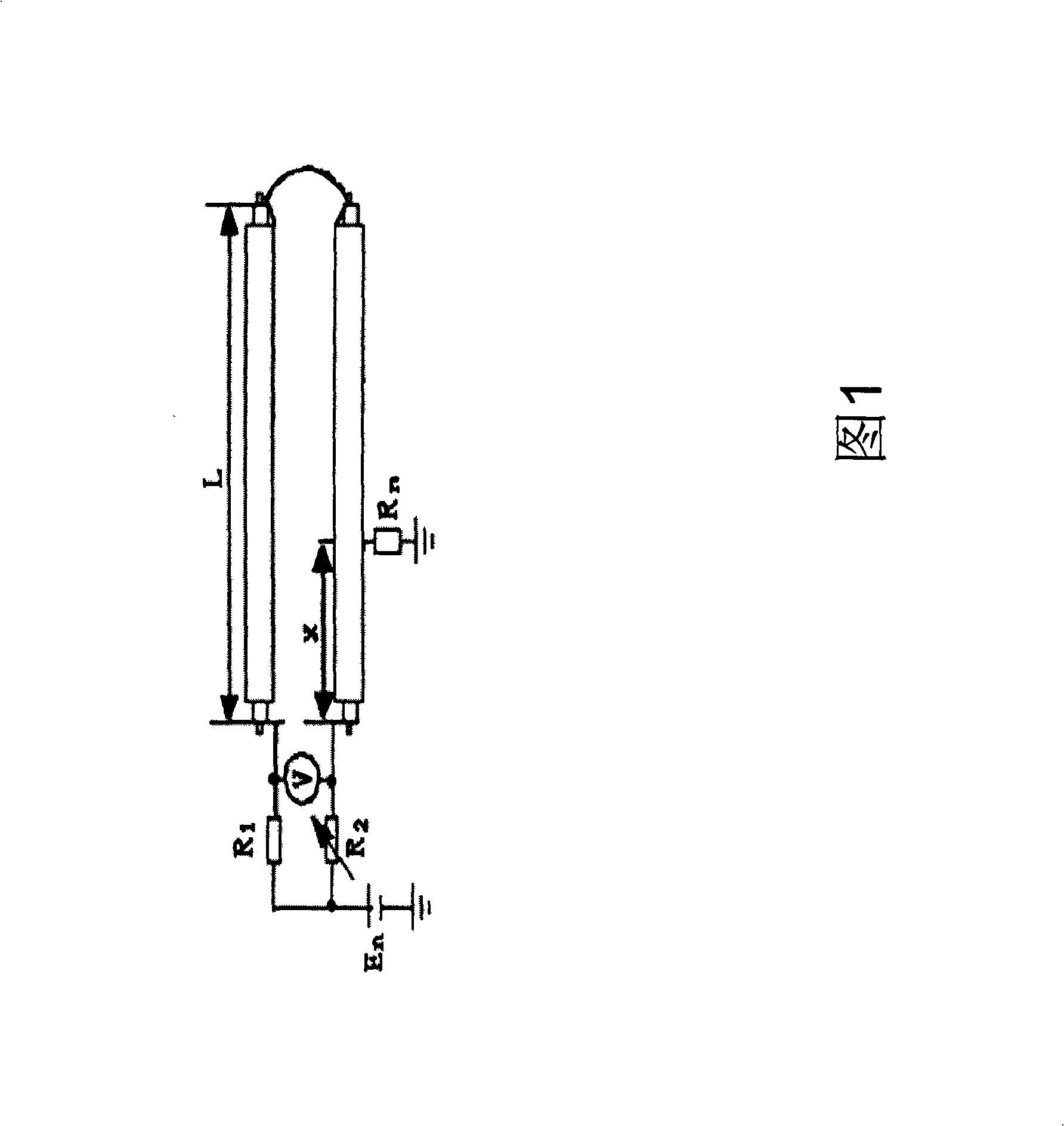

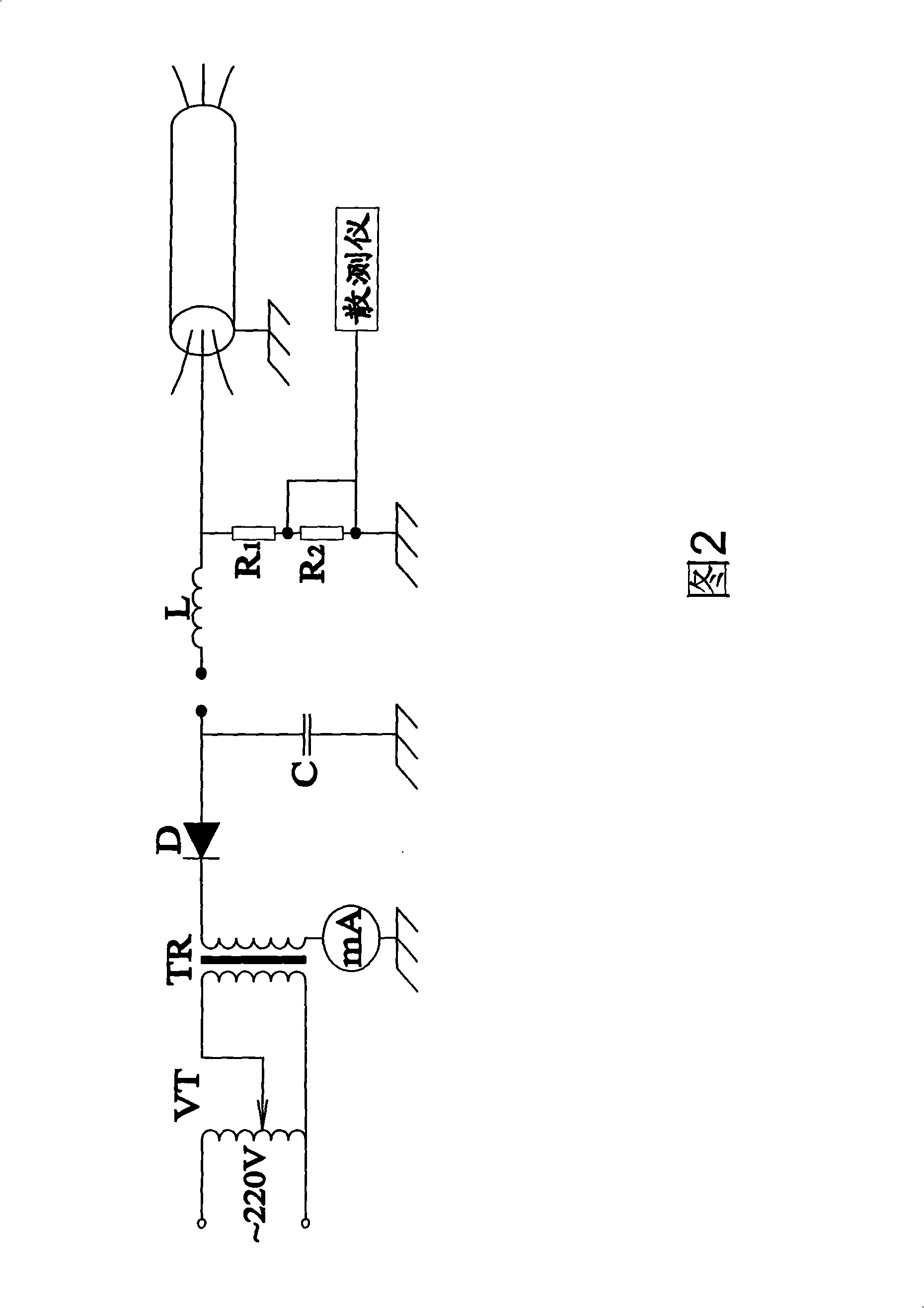

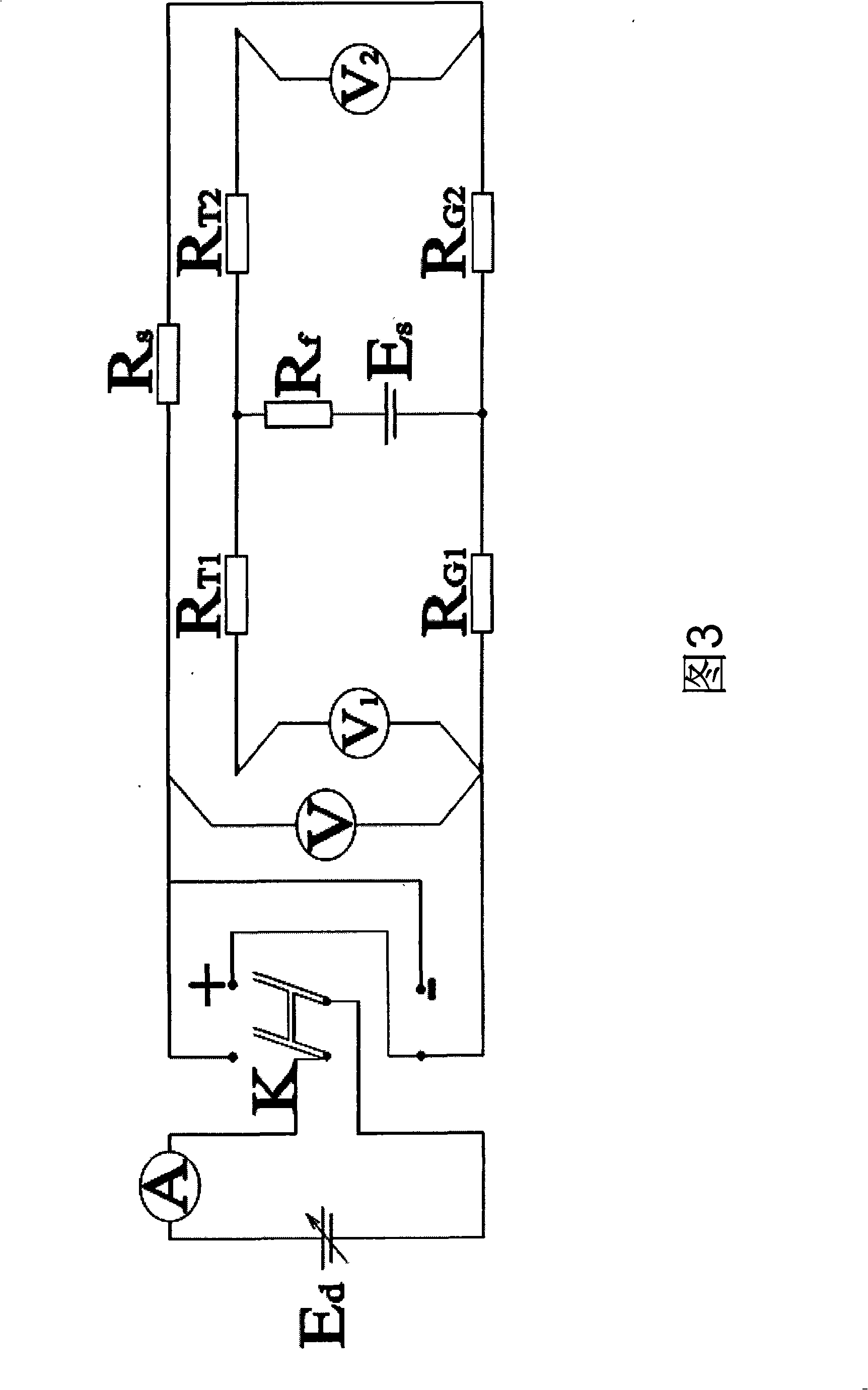

[0031] With reference to Fig. 3 and Fig. 4, first talk about the principle of the present invention, its basic principle is based on the characteristics that the cable is uniform along the line, the length of the cable is proportional to the resistance of the conductor core wire and the resistance of the shielded copper tape, and the normal conductor core of the faulty cable is used Line R S , Faulty conductor core wire R T (including R T1 and R T2 ) and shielding copper tape R G (including R G1 and R G2 ) as the measurement circuit, add an adjustable low-voltage DC power supply E to the measurement circuit d After that, the cable shield copper tape R G The pressure drop per meter is also equal. Utilize faulty conductor core wire R T As a measuring line, through the cable fault grounding resistance R f with shield co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com