Diesel oil automobile, boat real time running oil consumption detection device

A technology for detection devices and motor vehicles, applied in the direction of measuring devices, machines/engines, mechanical equipment, etc., can solve the problems that it is impossible to obtain accurate actual fuel consumption values, the application of real-time detection products cannot be carried on the vehicle, and it is not suitable for diesel vehicles, ships, etc. , to achieve considerable social and economic benefits, accurate and reliable test data, and great value for promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

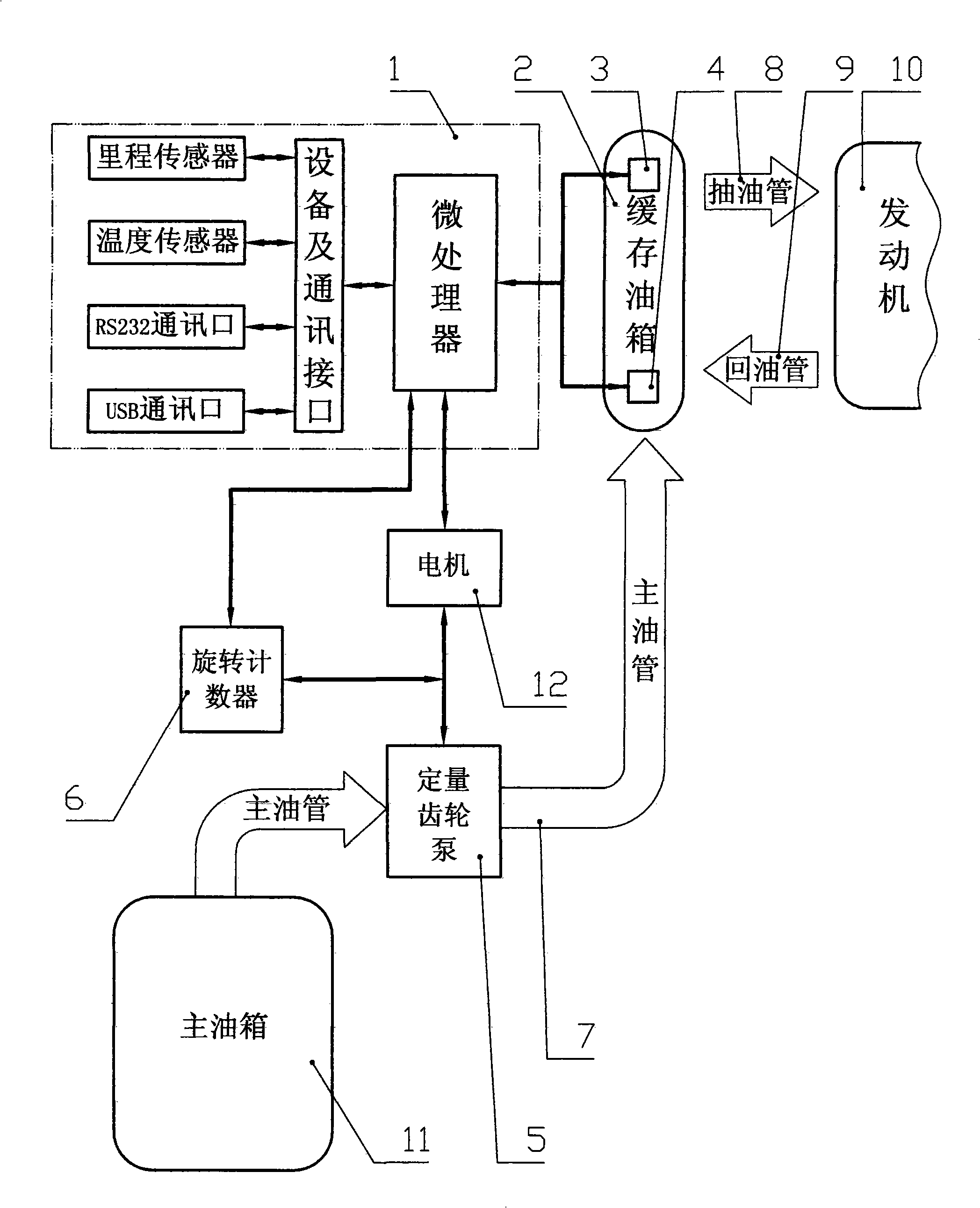

[0014] Now in conjunction with accompanying drawing, technical content of the present invention is described in detail:

[0015] The microprocessing main control board (1) is provided with barge interfaces including a mileage sensor, a temperature sensor, an RS232 communication port and a USB communication port, and the microprocessing main control board (1) is respectively connected to the upper liquid level sensor (3) is connected with the lower liquid level sensor (4), the motor (12) and the rotation counter (6); the buffer oil tank (2) is respectively connected with the microprocessing main control board (1), and the quantitative gear through the main oil pipe (7) The pump (5) is connected to the engine (10) through the oil suction pipe (8) and the oil return pipe (9), and the upper liquid level sensor (3) and the lower liquid level sensor (4) are respectively placed in the buffer oil tank (2) Both ends; the quantitative gear pump (5) is respectively connected with the buf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com