Production process for color-mixing denim and the color-mixing denim made thereby

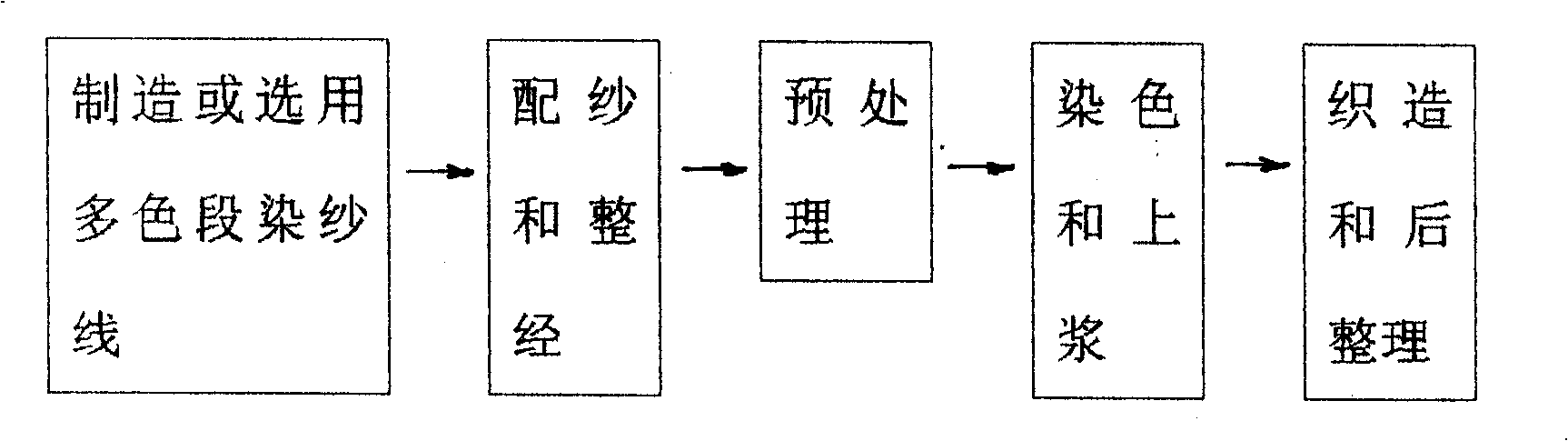

A production process and technology for denim fabrics, applied in the field of textile printing and dyeing, can solve the problems of difficulty in maintaining the rough and simple style of denim fabrics, difficult to control the arrangement and combination rules, and heavy repetitive labor workload, etc., to achieve rich patterns and reduce repetitive labor. , fashionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: Utilize the mixed-color denim production process of the present invention, use a kind of yarn that has been dyed in sections to show red and white spaced apart from each other, and another kind of yarn that has been dyed in sections and show yellow and white spaced apart from each other yarn, and another all-white yarn, to create a blue-dominant melange denim with a multi-coloured slub effect.

[0046] According to the technical scheme of the present invention, the above-mentioned mixed-color denim fabric with the effect of multi-color imitation slub yarn is manufactured according to the following production technology:

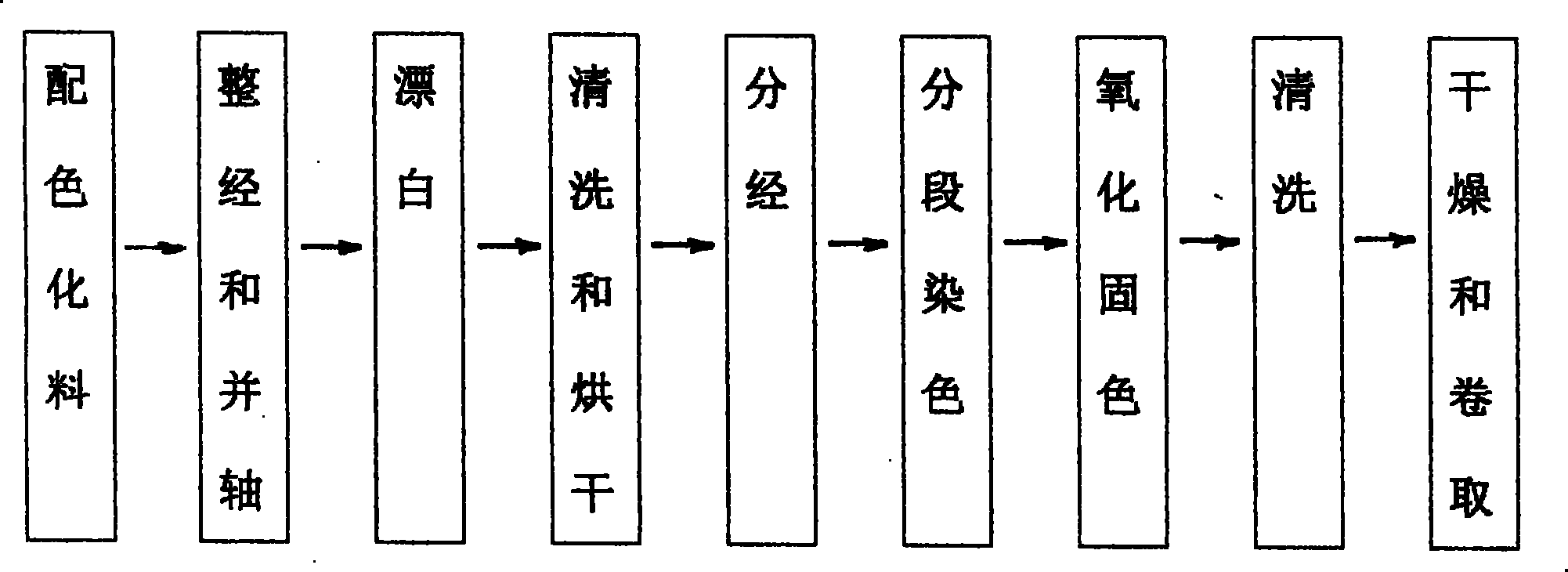

[0047] ① Yarn matching and warping: According to the density and color requirements of the mixed color fabric, choose 12 S 2016 pure cotton white yarns are coiled on 4 warp beams, each warp beam is coiled with 504 yarns 12 S Cotton White Yarn, 12 S Cotton white and yellow spaced multi-color space dyed yarn 1512 coiled on 3 warp beams, e...

Embodiment 2

[0054] Embodiment 2: Utilize the mixed-color denim production process of the present invention, use a kind of yarn that has been segmented dyed to present green, blue, red and white spaced from each other, and another kind of yarn that has been segmented dyed and exhibits Spaced yarns of yellow, purple, brown and white, and an all-white yarn, create melange denim with a predominant gray-black color.

[0055] According to the technical scheme of the present invention, the above-mentioned main color is gray-black mixed color denim is manufactured by the following production technology:

[0056] ① Yarn matching and warping: According to the density and color requirements of the mixed color fabric, choose 12 S 2016 pure cotton white yarns are coiled on 4 warp beams, each warp beam is coiled with 504 yarns 12 S Cotton White Yarn, 10 S Cotton yellow, purple, brown and white spaced multi-color space dyed yarn 1410 coiled on 3 warp beams, each warp beam coiled 470 yarns 10 S Pure c...

Embodiment 3

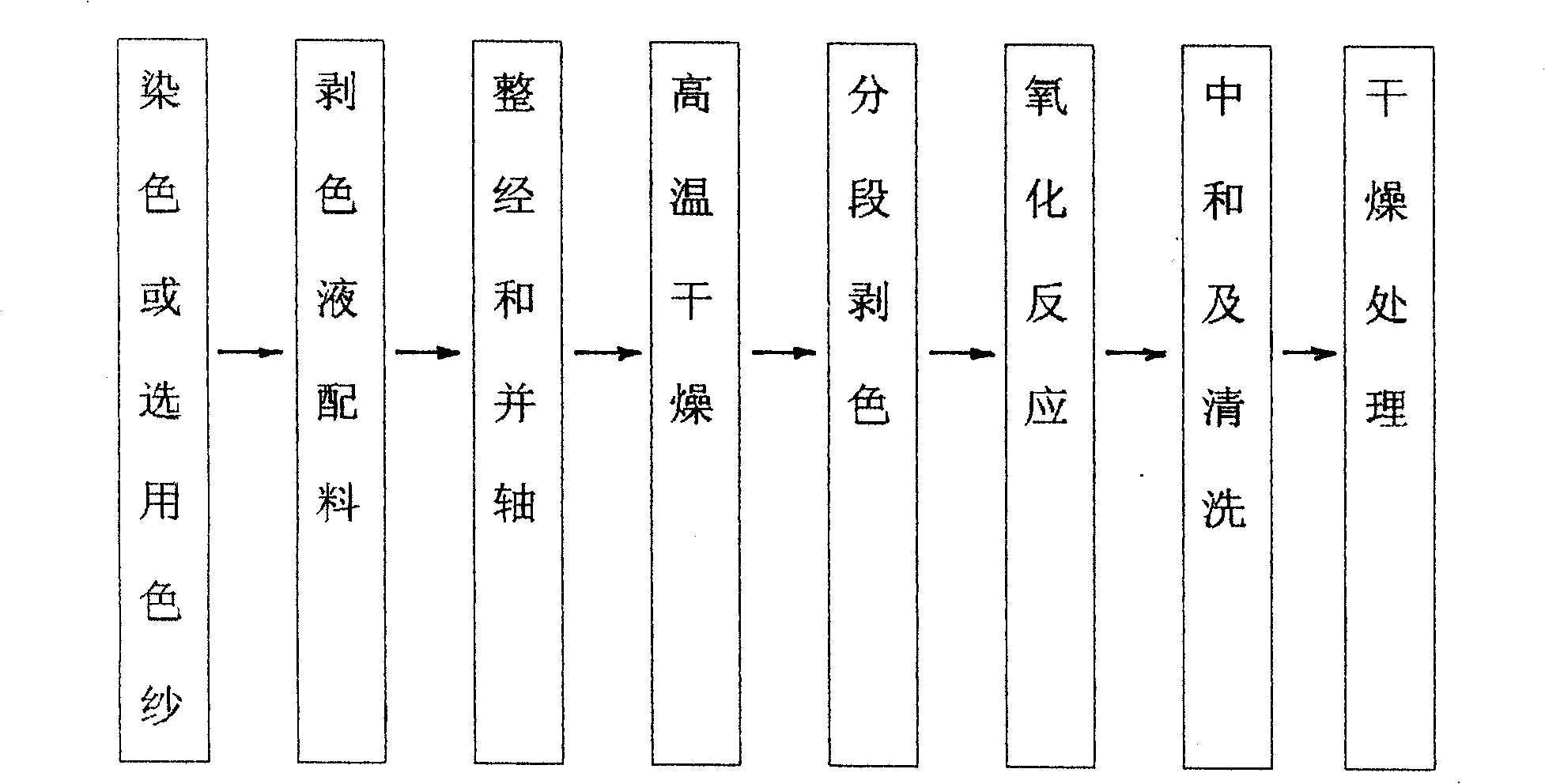

[0063] Embodiment 3: Utilize the production process of the multi-color segment dyed yarn of the present invention, directly produce the piece yarn belt with the pattern pattern of green, yellow and white intervals on many ordinary plain yarns, and then use it on the sizing-dyeing combined machine It is dyed with blue as the main base color of the fabric, so that printing, dyeing and sizing can be completed at one time, and finally weaved into a mixed-color denim fabric with a semi-mercerized effect.

[0064] According to the technical solution of the present invention, firstly, the drum-type multi-color segment dyeing and printing device capable of segmentally dyeing multiple yarns is effectively connected and installed on the front end of the sizing-dyeing combined machine, and the multi-color segment dyeing device is The required green and yellow patterns are dyed intermittently on the white yarn, so as to produce multi-color segment-dyed yarns with white, green and yellow se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com