Method for preparing flower-shaped spinelle cobalt ferrite powder

A cobalt ferrite and spinel technology, which is applied in the field of preparation of inorganic non-metallic magnetic materials, can solve problems such as difficulty in morphology control, and achieve high saturation magnetization and remanence, high coercivity and high purity. Effect

Inactive Publication Date: 2008-10-22

HARBIN ENG UNIV

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Moreover, the co-precipitation method has realized the synthesis of rod-shaped, flower-shaped binary oxides (such as ZnO, CeO2, etc.), but due to the existence of a large number of tetrahedral and octahedral vacancies in the crystal structure of ferrite, its morphology is controlled. It is more difficult than simple binary oxides, so so far, the cobalt ferrite synthesized by co-precipitation method is mostly granular, and there is no report on the synthesis of flower-shaped ferrite

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

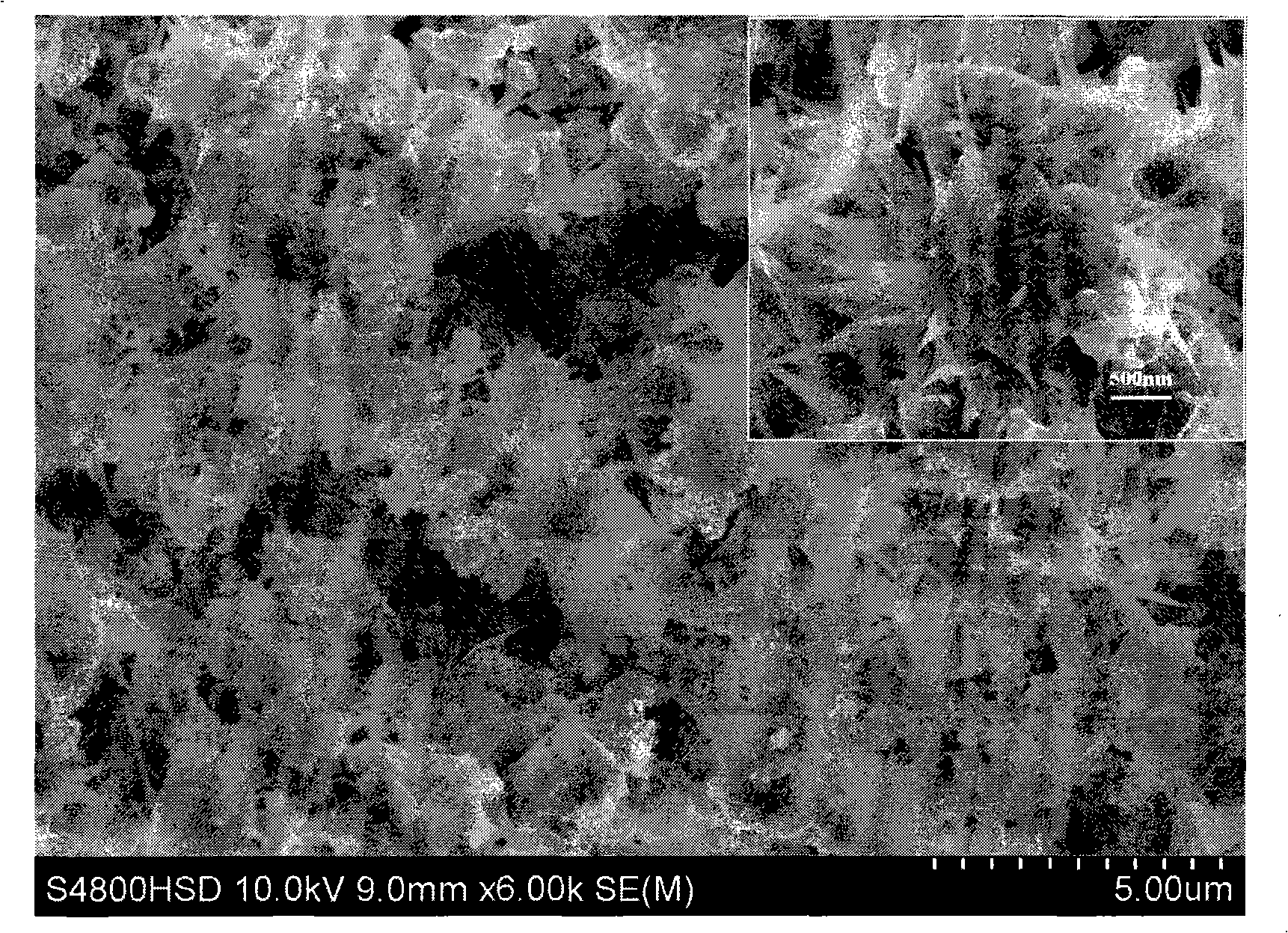

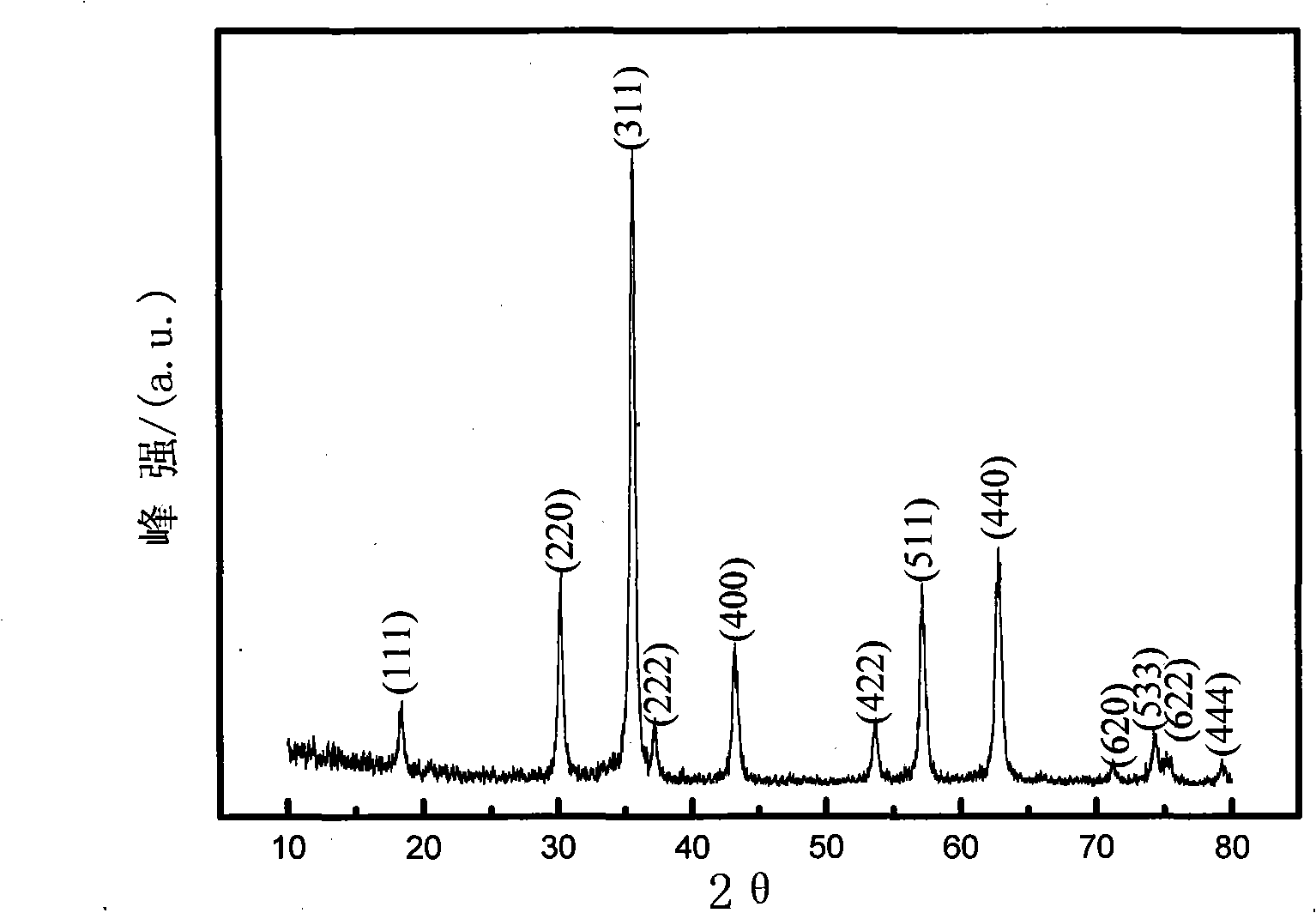

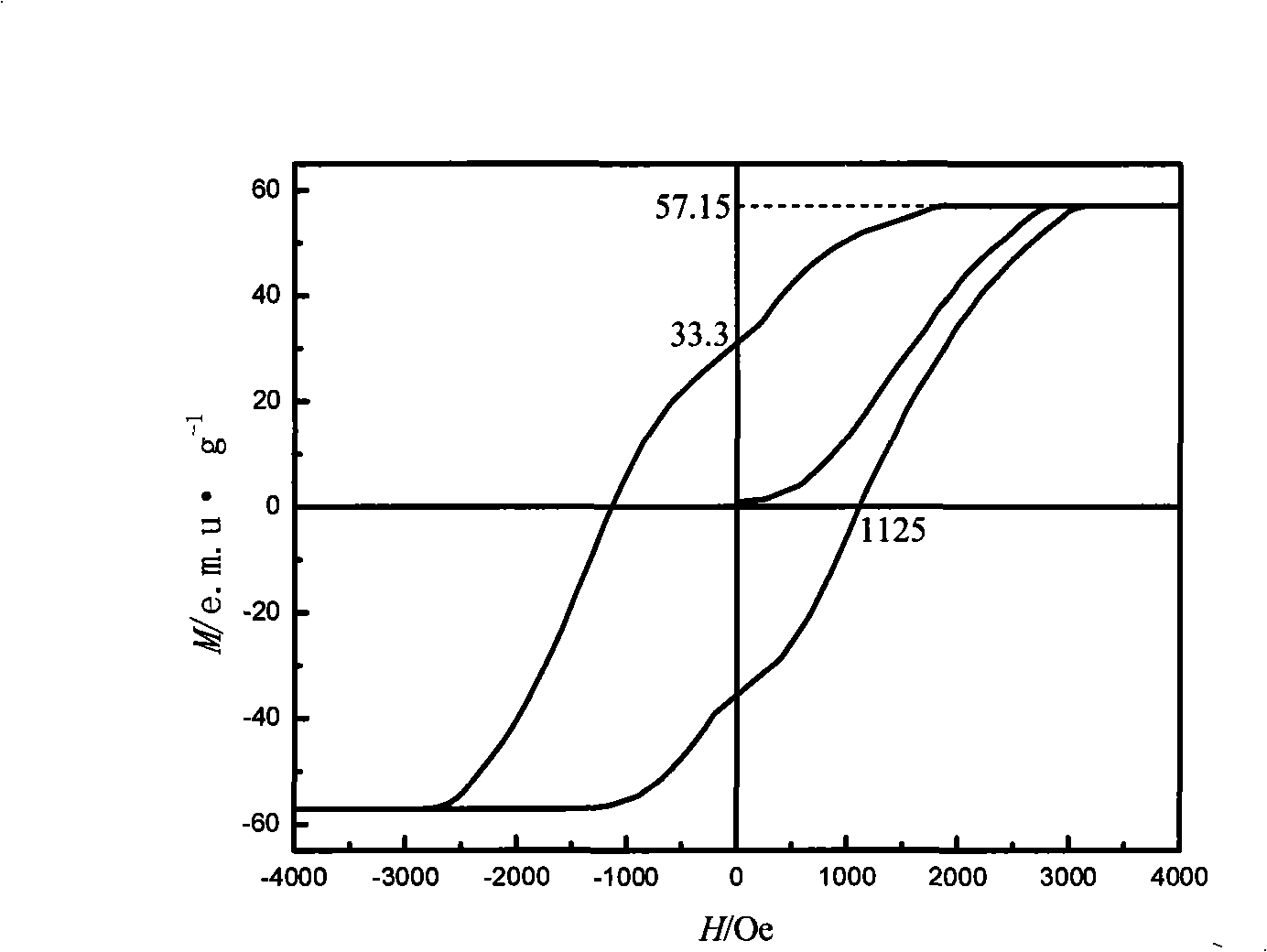

The invention provides a preparation method for floriated spinelle cobalt ferrite powder. The method procedure is that: a certain quantity of saturated oxalic acid solution is measured; corresponding quantities of cabaltous nitrate and ferric nitrate are weighted according to a ratio of preparing 0.002mol of ferrite by per 100ml of the saturated oxalic acid solution, wherein, the theoretical stoichiometric proportion of the ferrite is 1:2, and the cabaltous nitrate and the ferric nitrate are added into the oxalic acid solution; 0.2 to 0.5g PEG of surface active agent is added and stirred for 0.5 to 1.0 hour to prepare well-proportioned mixture solution; NaOH is used for regulating the PH value to be 12 and the well-proportioned mixture solution is stirred with magnetic force at room temperature for 0.5 to 1.0 hour until the sample generates a lot of precipitates; heating and stirring are carried out for 2 to 3 hours in a water-bath with the temperature of 75 DEG C to 85 DEG C to get a precursor; the precursor is washed sequentially by alcohol and distilled water for a plurality of times; the precursor is dried at the temperature of 80 DEG C; the dried precursor is ground into refined powder; and the refined power is roasted for 6 hours at the temperature of 800 DEG C. The floriated ferrite prepared by the invention has the advantages of high purity quotient, simple technique, being easy to control the pattern and low cost. Compared with a traditional coprecipitation method, a small quantity of the surface active agent is added to assist the formation of the floriated spinelle cobalt ferrite before regulating the PH value.

Description

Preparation method of flower-shaped spinel cobalt ferrite powder (1) Technical field The invention relates to a method for preparing an inorganic non-metallic magnetic material, in particular to a method for preparing flower-shaped spinel cobalt ferrite powder. (2) Background technology In recent years, the research on the preparation of oxides with special morphology has attracted widespread attention at home and abroad, and many oxides with special morphology (such as ZnO, TiO2, etc.) have been reported one after another. The crystals that have been prepared include nanoribbon crystals, nanowalls, tubes, rings, columnar arrays, nanoflowers, tetragonal crowns, hexagonal stars, pencils, columnar arrays, hexagonal helices, and wheat circle structures. Since the size and shape of nanoparticles have a significant impact on their physical and chemical properties, nanomaterials with special morphology have significant changes in properties compared to bulk materials. The curre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B35/26C04B35/622

Inventor 侯相钰冯静钟世强张密林

Owner HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com