Numerical control device of hot air blower and controlling method thereof

A technology of numerical control device and hot air blower, which is applied to other household appliances, household components, household appliances, etc., can solve the problems of lack of flexibility and achieve the effect of ensuring the sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

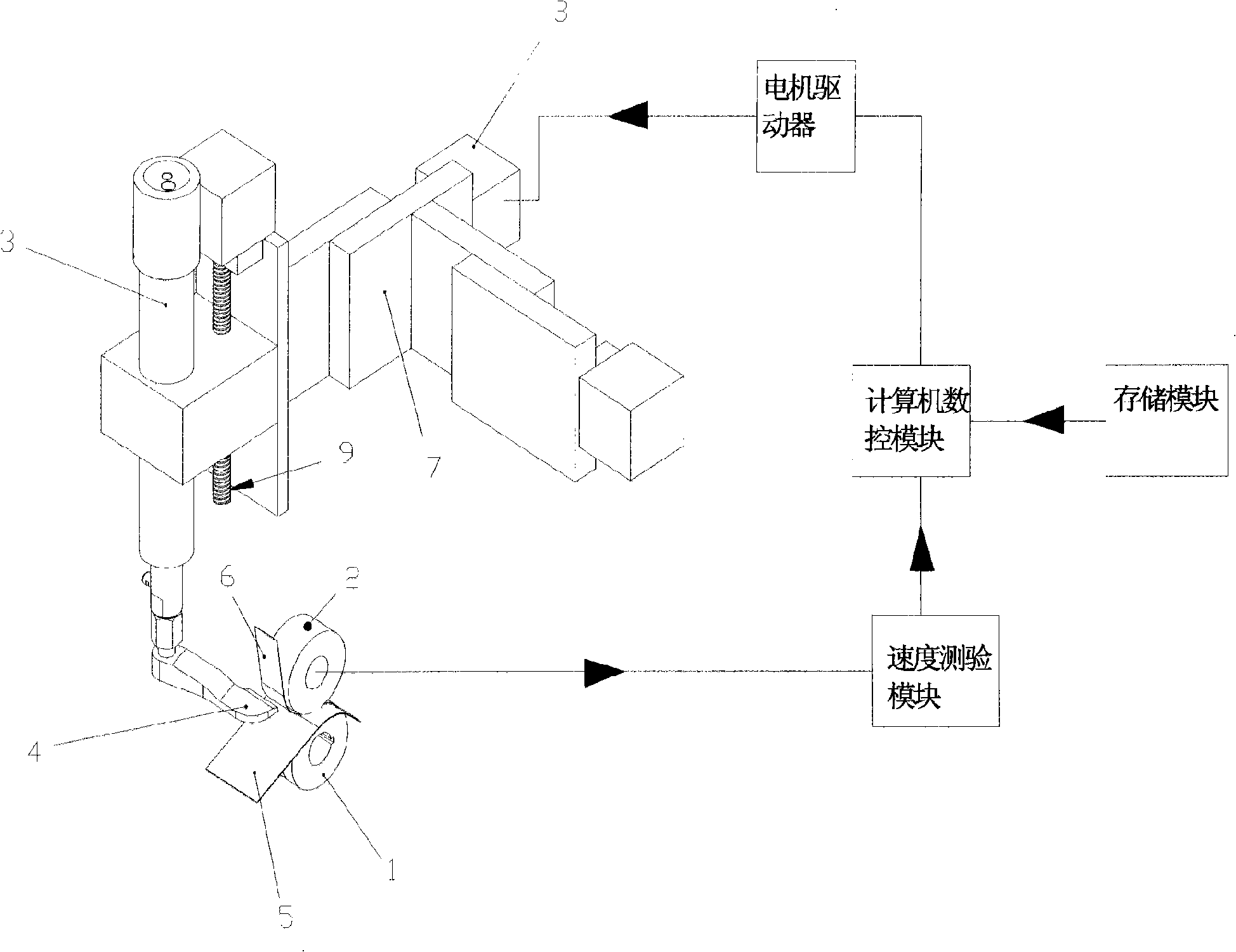

[0025] like figure 1 As shown, the roller 1 and the roller 2 of the hot air blower rotate synchronously and oppositely, the adhesive tape 6 is placed on the roller 2, and the material 5 is placed between the roller 1 and the roller 2. When the hot air blower is working, the numerically controlled air nozzle positioning device 7 first calls the sealing control command from the memory module, and drives the air nozzle 4 to move quickly to a preset position through the motor driver, and the air nozzle 4 blows hot air through the air heater 3 , the tape 6 near the tuyere becomes viscous after absorbing enough heat, and is sealed and bonded to the material 5 after being rolled and pressurized by the roller 1 and the roller 2.

[0026] In this embodiment, the position of the tuyere 4 will shift rapidly according to the change of the sealing speed. First, the speed when the material is actually sealed is tested by the speed test module; then the theoretical speed of the current mater...

Embodiment 2

[0028] As a preferred solution of the present invention, the number of the motor 8 and the transmission device 9 can be respectively set to three, and each motor is connected to the corresponding transmission device. When the hot air blower is working, after the air nozzle reaches the preset position, firstly by changing the sealing control instruction in the memory module in the numerical control air nozzle positioning device 7, then the instruction is sent to the computer numerical control module, and the motor driver is controlled by the computer numerical control module. Its control drives the motor 8 representing a certain direction, and the motor drives the air nozzle 4 to move together with the transmission device connected to it. The three-dimensional movement of the air nozzle 4 up and down, left and right, or front and back can be realized by completing the driving of the above three motors and the three transmission devices through the motor driver.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com