Embossment device of cylindrical wooden wares

A wood product and cylindrical technology, which is applied to the field of embossing devices for cylindrical wood products, can solve the problems of being unsuitable for mass production and low efficiency, and achieve the effects of being protected from being burned out, being easy to use, and easy to disassemble and assemble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

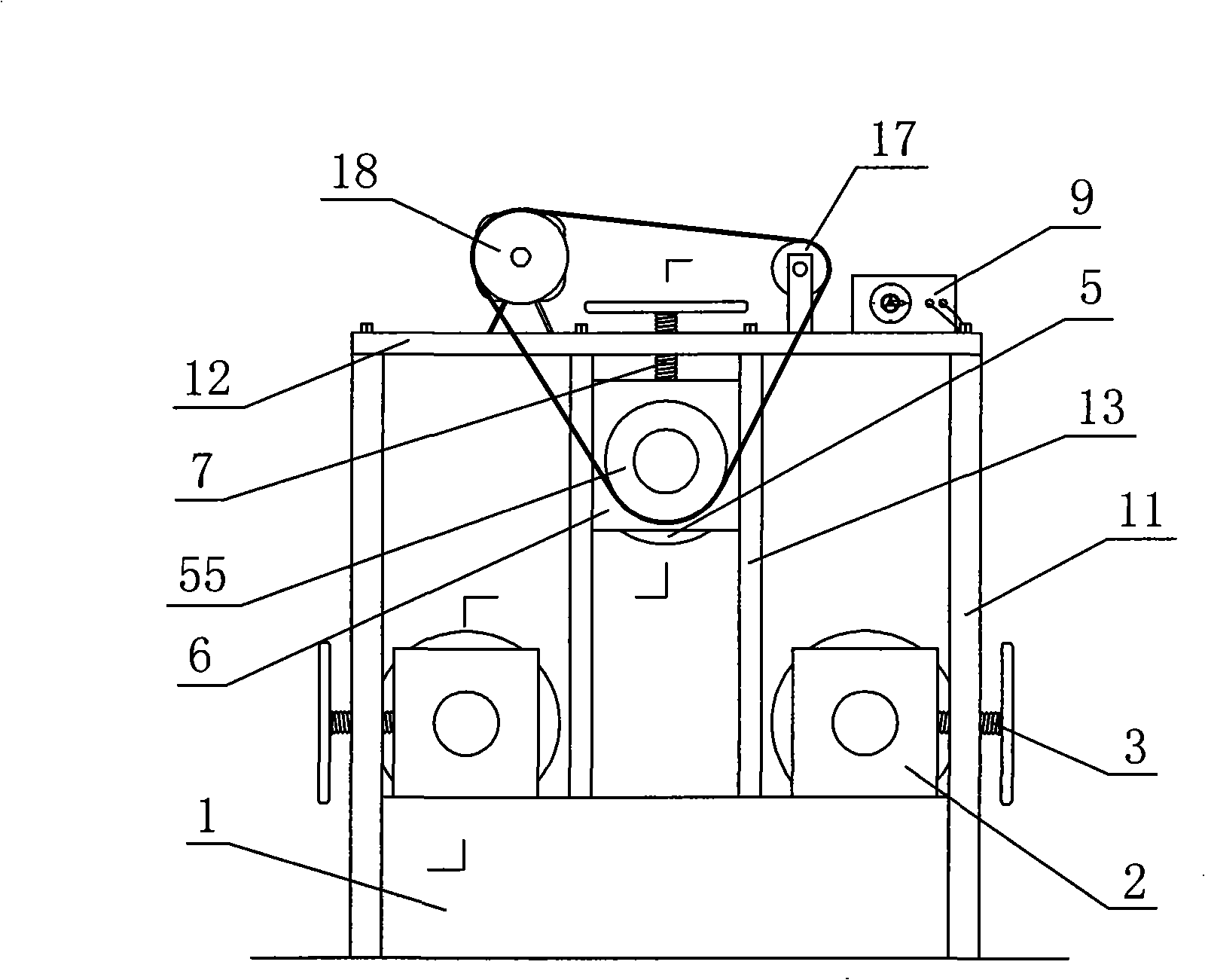

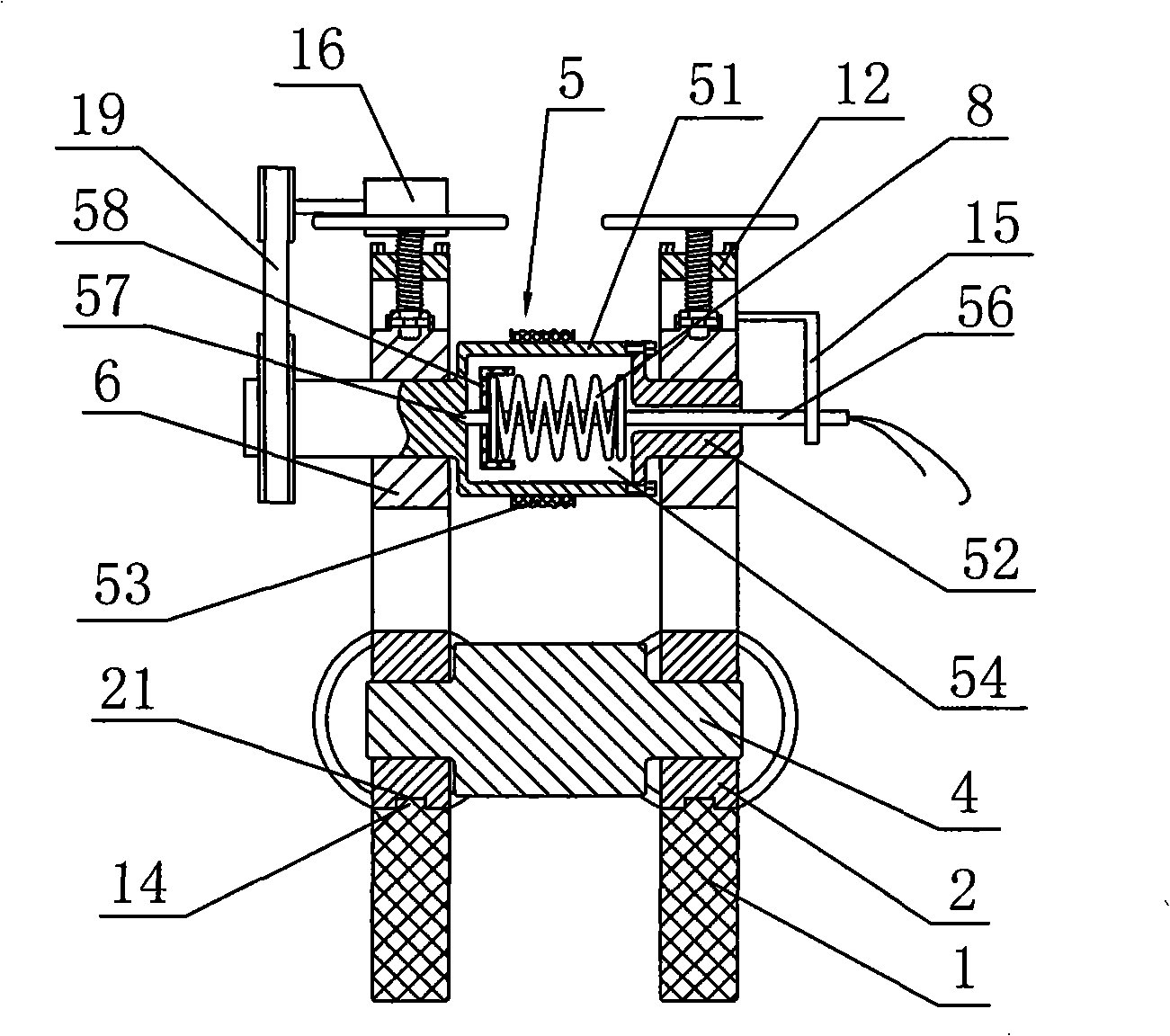

[0018] As shown in the figure, an embossing device for cylindrical wood products includes a base 1 and a large bracket 11 fixedly arranged on the base 1. 11 is provided with a small bracket 13, one end of the small bracket 13 is fixedly arranged on the base 1, the other end of the small bracket 13 is fixedly connected with the horizontal plate 12, and the base 1 is provided with two pairs for connecting the first finale 4, the transverse shaft seat 2, the transverse shaft seat 2 is provided with a transverse guide groove 21, the base 1 is provided with a transverse guide rail 14 matching with the transverse guide groove 21, the large bracket 11 is provided with a transverse adjustment screw 3, and the transverse shaft seat 2. It is fixedly connected with the horizontal adjusting screw rod 3. A pair of longitudinal shaft seats 6 for axially con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com