Multi-source vacuum evaporation device having multi-layer radial type evaporation source distribution structure

An evaporation source and evaporation technology, applied in vacuum evaporation coating, sputtering coating, coating, etc., can solve the problems of film uniformity, shadow effect, too large chamber, etc., and achieve the reduction of vacuum chamber space , Prevent shadow effect, uniform film formation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

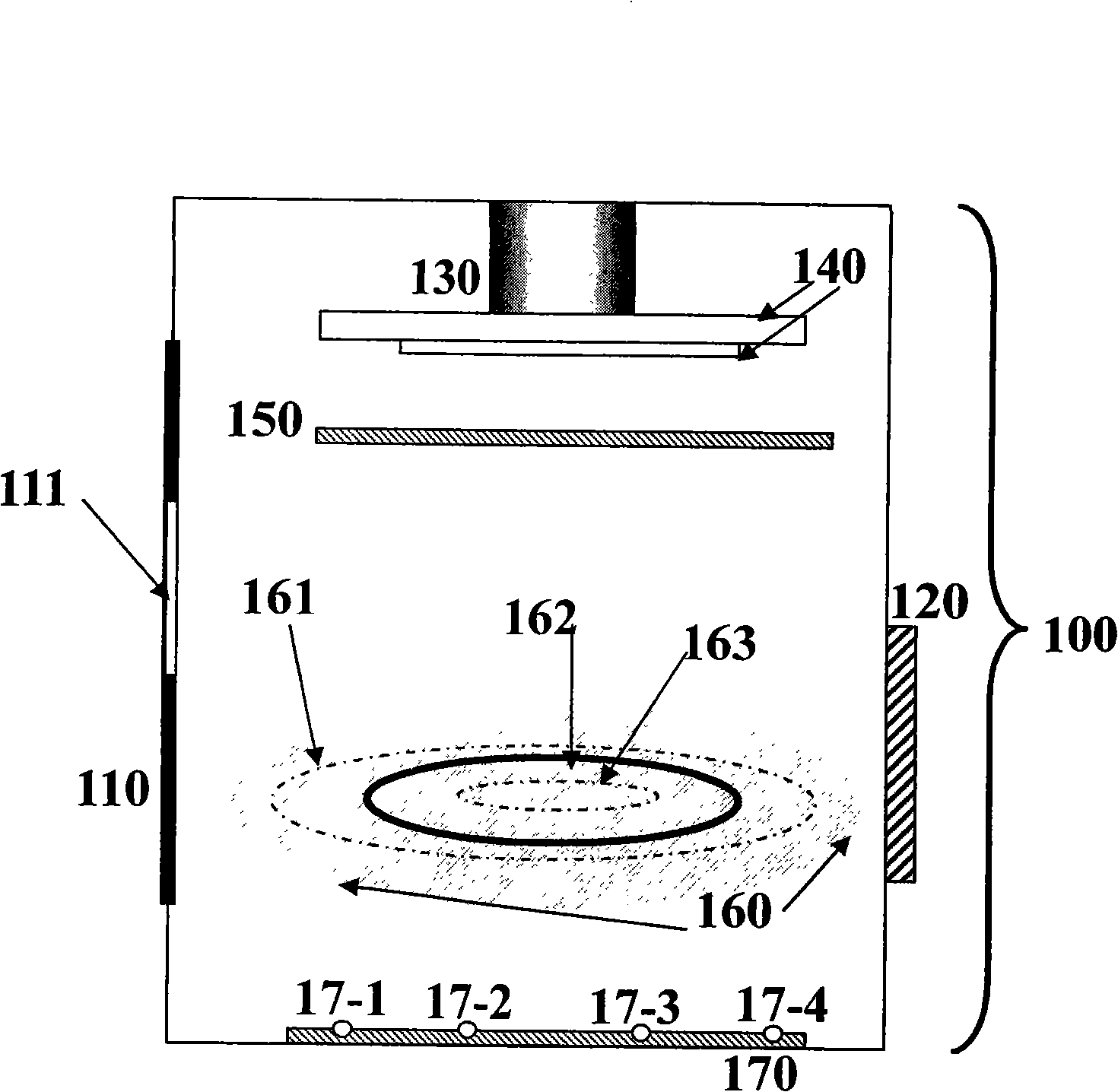

[0028] Embodiment 1 is an example of simply describing the multi-evaporation source system of this patent. exist figure 1 The shown vacuum chamber 100 has a cylindrical structure inside, with an inner diameter of 360 mm, a height of 560 mm, and a front door 110 with a size of 200 mm×350 mm. On the horizontal plane perpendicular to the central axis of the longitudinal vacuum chamber, from top to bottom, there are sample base frame horizontal plane 140 and evaporation source position horizontal plane 160, the vertical distance between sample base frame horizontal plane 140 and evaporation source position horizontal plane 160 is 300mm. The position of the evaporation source is centered on the central axis of the vacuum chamber, and in the horizontal plane 160 of the position of the evaporation source, it is divided into two layers of radial distribution: an inner ring 163 and an outer ring 161 . The positions of the evaporation sources in the outer ring 161 are distributed withi...

Embodiment 2

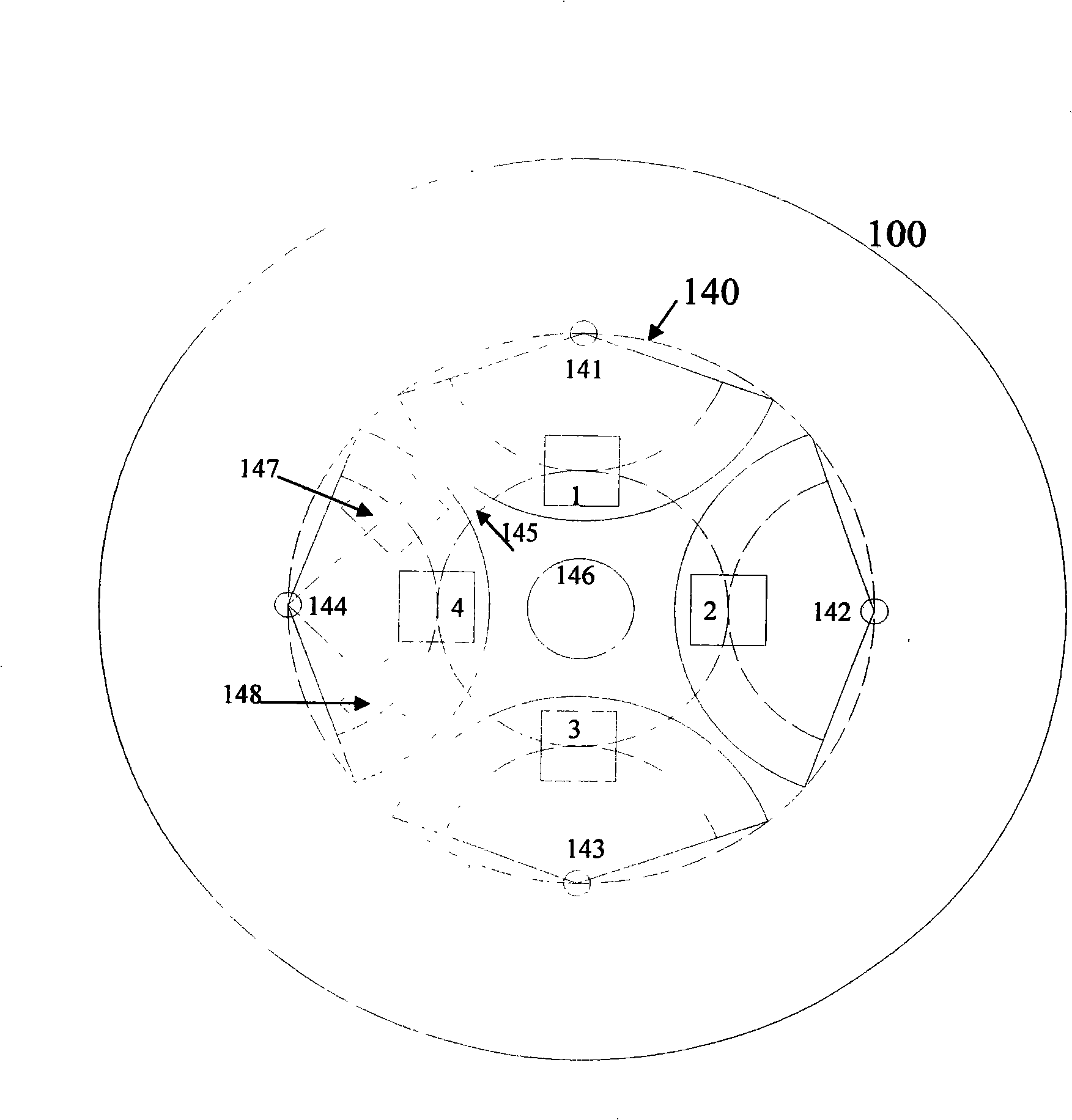

[0029] Embodiment 2 is a plan view of the horizontal plane of the sample substrate holder in the actual system. Such as figure 2 As shown, the inner diameter of the vacuum chamber 100 is 360 mm; the shapes of the first independent small baffle 141, the second independent small baffle 142, the third independent small baffle 143, and the fourth independent small baffle 144 are Fan-shaped, with a radius of 75mm, and their axes are located on a circle with a diameter of 220mm; above them, in a clockwise direction, there are sequentially distributed a first mask 147 and a second mask 148, with a size of 28mm× 28mm, and its center forms an angle of ±45° with the center line of the sector. When the small sample baffle rotates clockwise, it provides the functions of metal mask, sample baffle and organic mask in three fixed positions respectively. The centers of the first sample to be evaporated position 1, the second sample to be evaporated to position 2, the third sample to be eva...

Embodiment 3

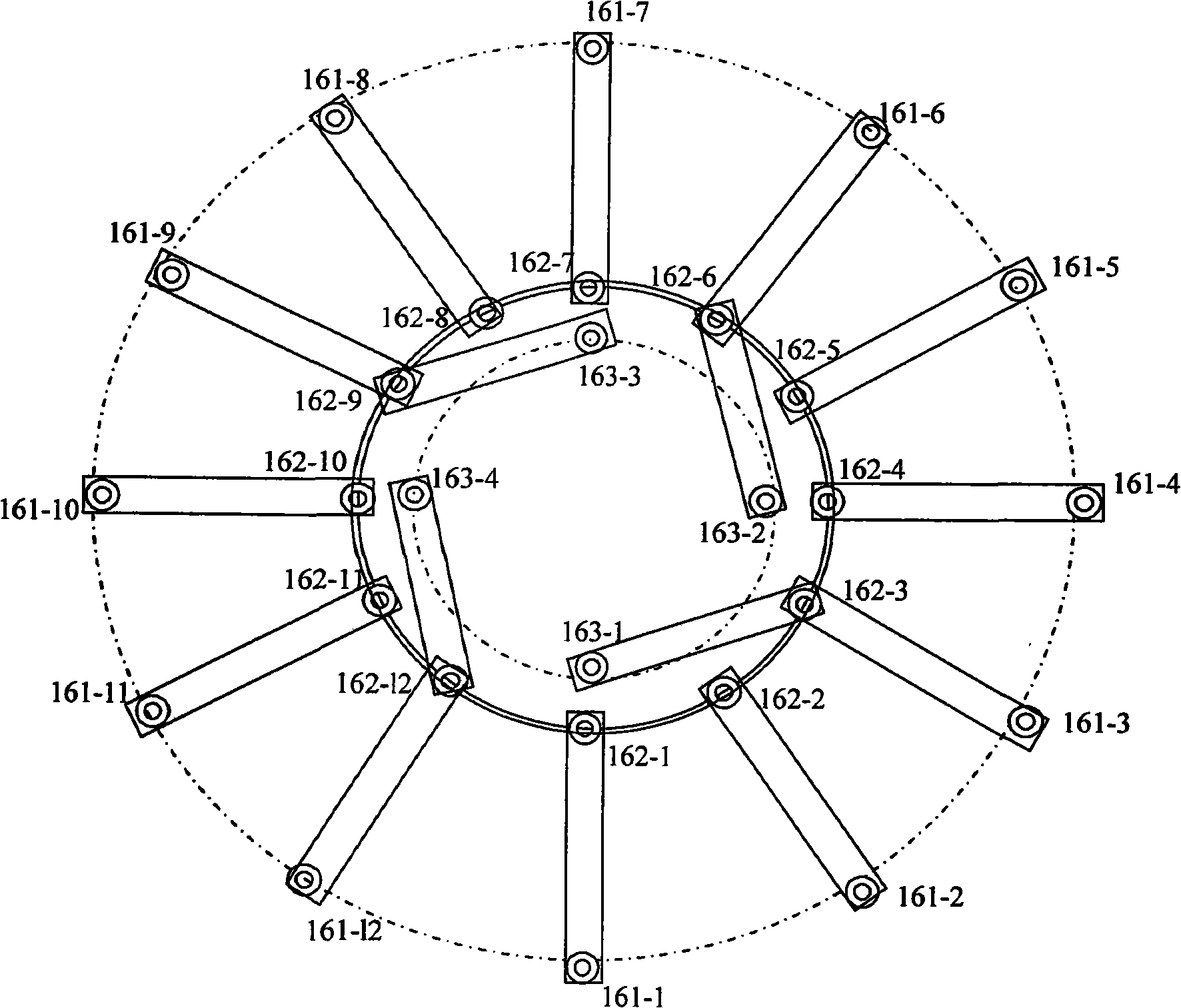

[0030] Embodiment 3, description of the horizontal plane of the evaporation source at the bottom of the vacuum chamber. Such as image 3 , 4 , 5, and 6 show the multi-layer radiation distribution of evaporation sources, the total number of evaporation sources and the number of inner layer evaporation sources are 16, 15, 14, 13, and 4, 3, 2, 1, respectively. The electrodes on the outer ring 161 are distributed on a circle with a diameter of 270 mm. By connecting with the common grounding ring 162 with a diameter of 130 mm, 12 outer layer first evaporation sources S-1 and outer layer with a diameter of 200 mm can be formed. The second evaporation source S-2, ..., the twelfth evaporation source S-12 of the outer layer; the electrodes on the inner ring 163 are distributed on a circle with a diameter of 110mm, and can form 4 by being connected with the common grounding ring 162 ( image 3 ), 3 ( Figure 4 ), 2 ( Figure 5 ), 1 ( Figure 6 ) inner layer evaporation sources, na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com