Blast furnace-converter interface 'compact one tank mode' process

A compact, blast furnace technology, applied in the field of metallurgical industry, can solve the problems of not meeting the requirements of compact design, prolonged waiting time, low measurement accuracy, etc., and achieve the effects of clean production, small system error and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

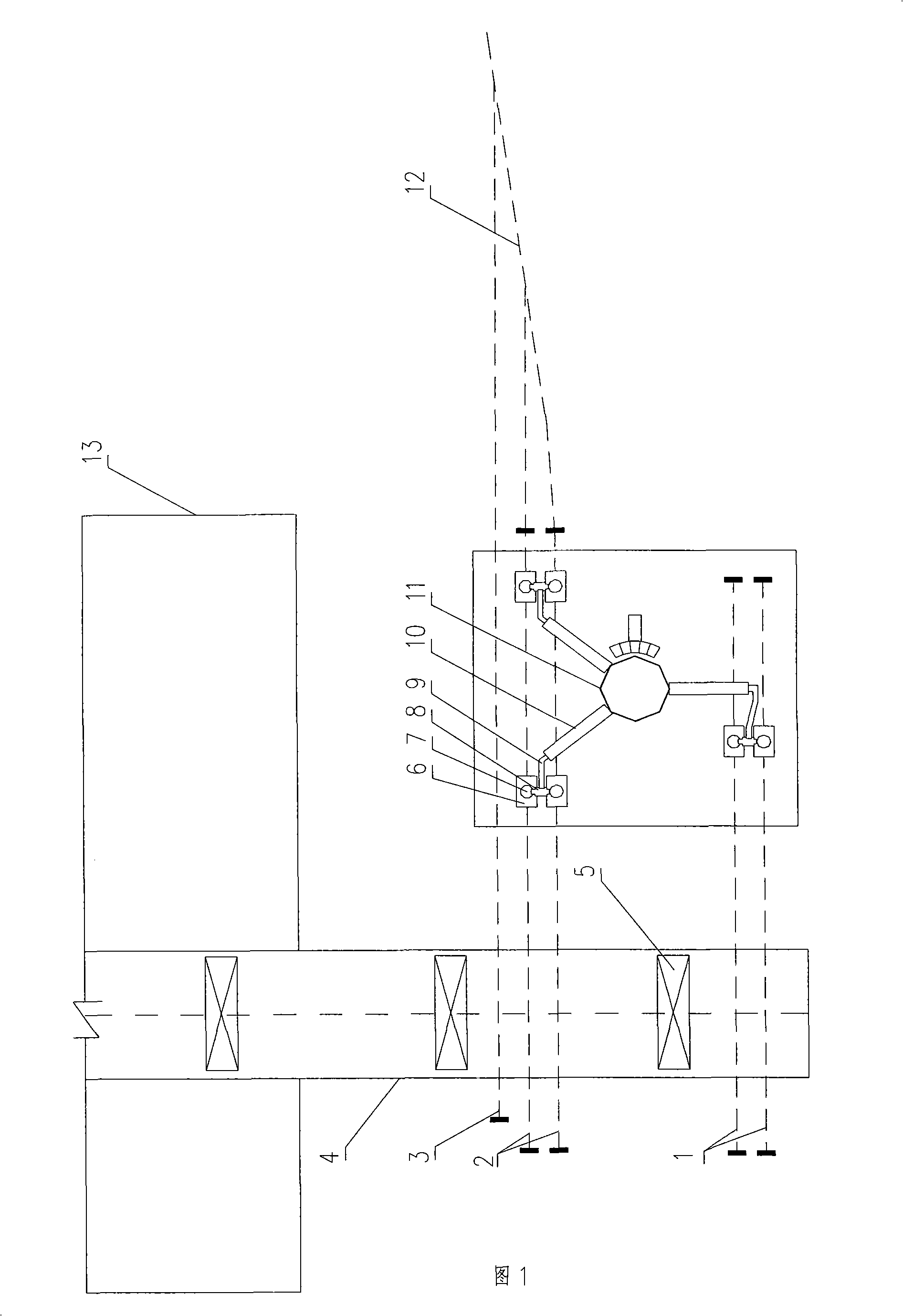

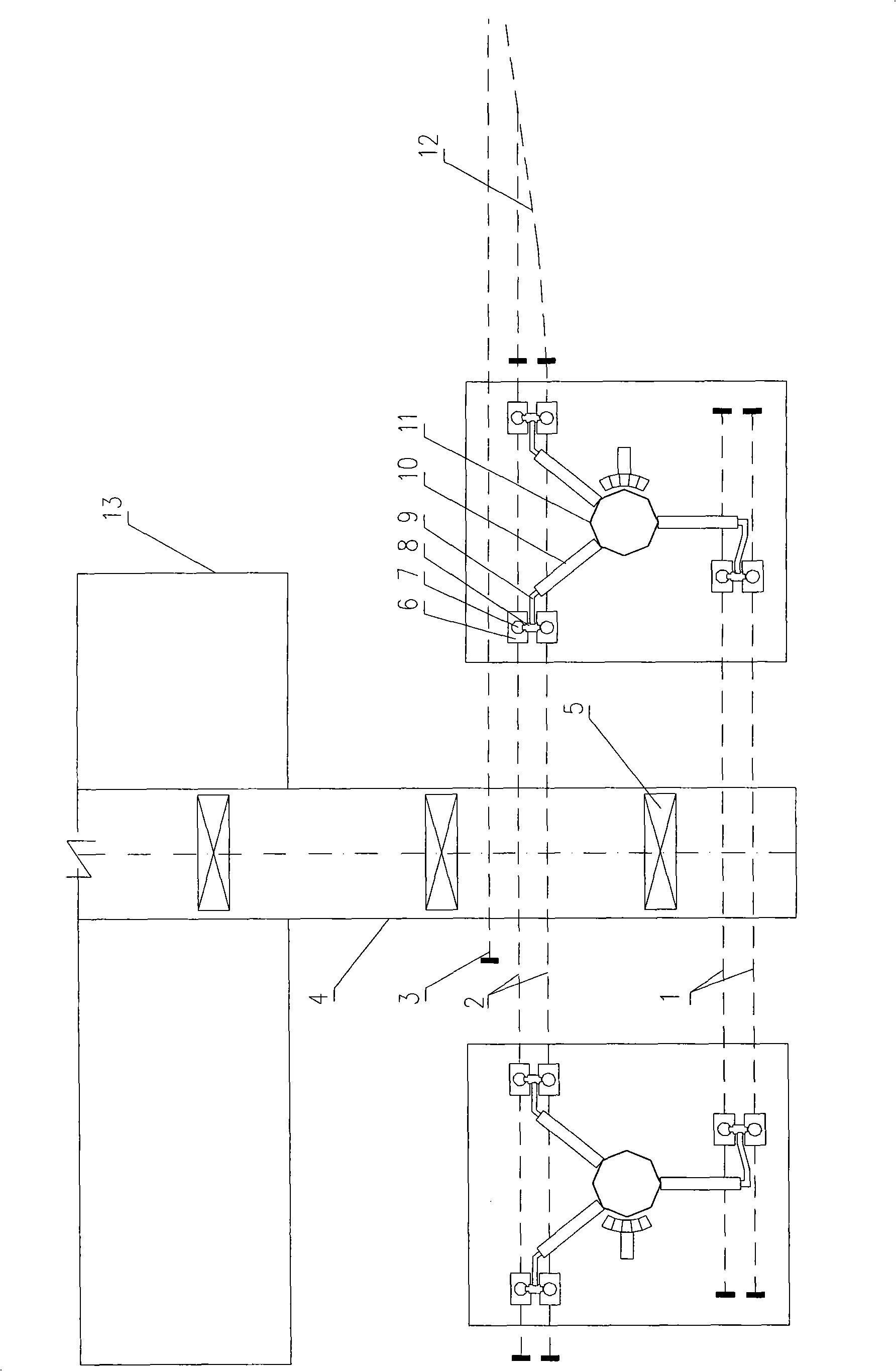

[0017] The present invention is described in detail below in conjunction with accompanying drawing:

[0018] As shown in Figure 1, a blast furnace is to a steelmaking workshop, in a working area composed of a steelmaking workshop 13 and a blast furnace 11, the blast furnace has three main trenches 10 and its iron trenches 9, three swing nozzles 8, two The straddle car operation line 1, two straddle car and railway mixed operation lines 2, one railway operation line 3, two receiving iron tanks 7 under each swing nozzle 8, and two straddle cars 6 are formed. On the side of the iron yard, the charging cross-factory building 4 of the steelmaking workshop is arranged next to the casting yard. The distance between the center of the blast furnace 11 and the center line of the charging span is less than 75 meters. Within the scope of work covered by the car 5; the receiving iron pot 7 used by the blast furnace 11 is placed on the over-span car 6 that can go straight and is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com