Preparation for nano-boehmite with diverse morphologies

A nano boehmite and boehmite technology, applied in the direction of alumina/aluminum hydroxide, can solve problems such as harsh operating conditions, and achieve the effects of easy operation, reduced production costs, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment one: concrete steps are as follows:

[0044] a. Dissolve 3mmol aluminum nitrate in 20ml deionized water to form a uniformly mixed solution;

[0045] b. Under stirring, add 20ml of absolute ethanol and mix well;

[0046] c. Under stirring at room temperature, add 1 mmol of sodium citrate to the above solution, and continue stirring for 50 minutes to form a uniformly mixed solution;

[0047] d. Transfer the uniformly mixed solution to a hydrothermal kettle, tighten the lid of the kettle, and place it in an oven at 220° C. for 48 hours. After the reaction, centrifuge and wash several times with deionized water and absolute ethanol.

[0048] e. Dry the sample obtained in step d at 80° C. for 12 hours to obtain boehmite with a core-shell structure, that is, a sphere-within-sphere structure.

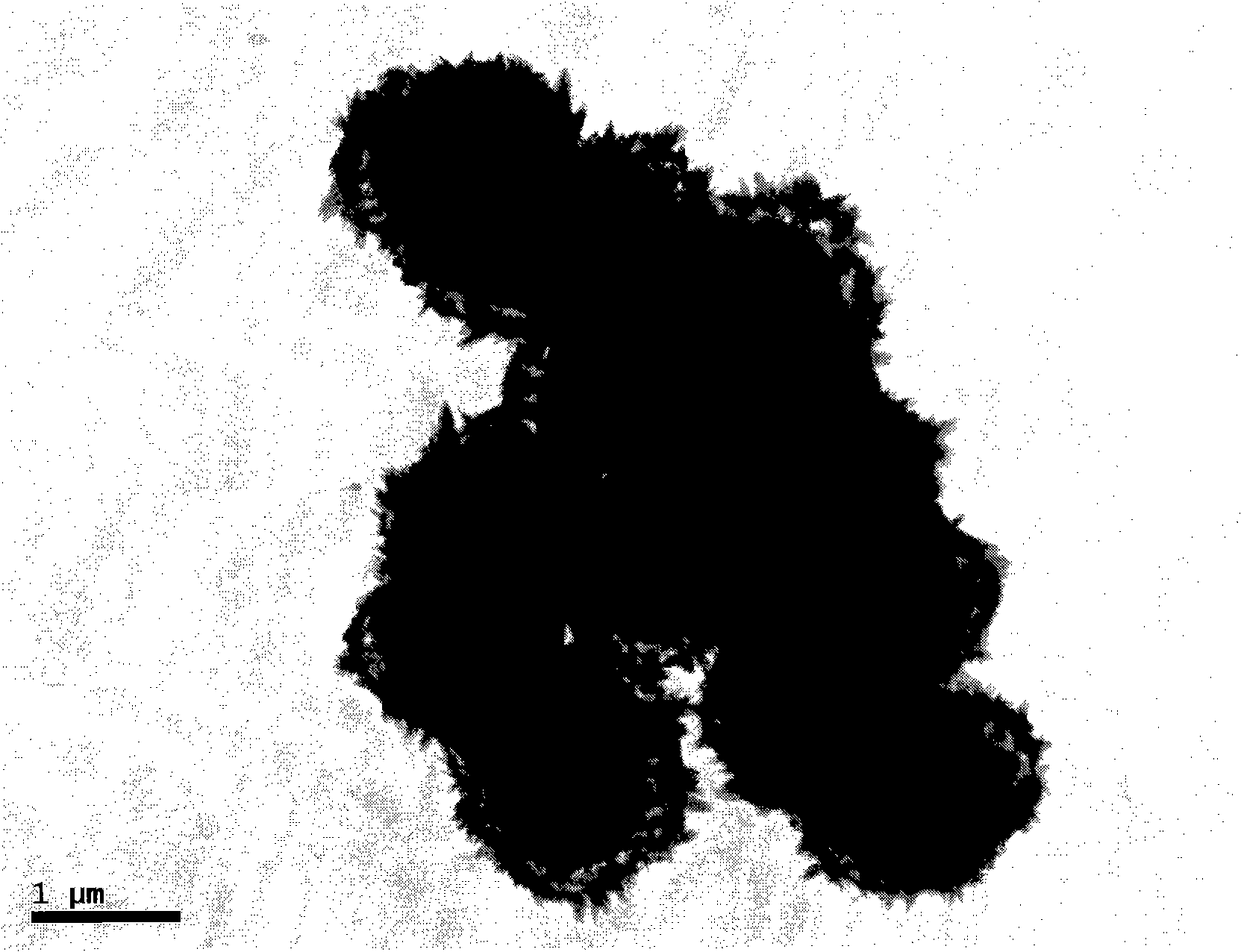

[0049] The product obtained in this example was characterized by a transmission electron microscope (TEM) on the morphology of the product. From figure 1 It can be seen th...

Embodiment 2

[0050] Embodiment two: concrete steps are as follows:

[0051] a. Dissolve 0.5mmol aluminum sulfate in 20ml deionized water to form a uniformly mixed solution;

[0052] b. Under stirring, add 20ml of absolute ethanol and mix well;

[0053] c. Under stirring at room temperature, add 0.5 mmol of sodium citrate to the above solution, and continue stirring for 30 minutes to form a uniformly mixed solution;

[0054] d. Transfer the uniformly mixed solution to a hydrothermal kettle, tighten the lid of the kettle, and place it in an oven at 180°C for 6-18 hours. After the reaction, centrifuge and wash several times with deionized water and absolute ethanol.

[0055] e. Dry the sample obtained in step d at 60° C. for 12 hours to obtain boehmite with a solid spherical structure.

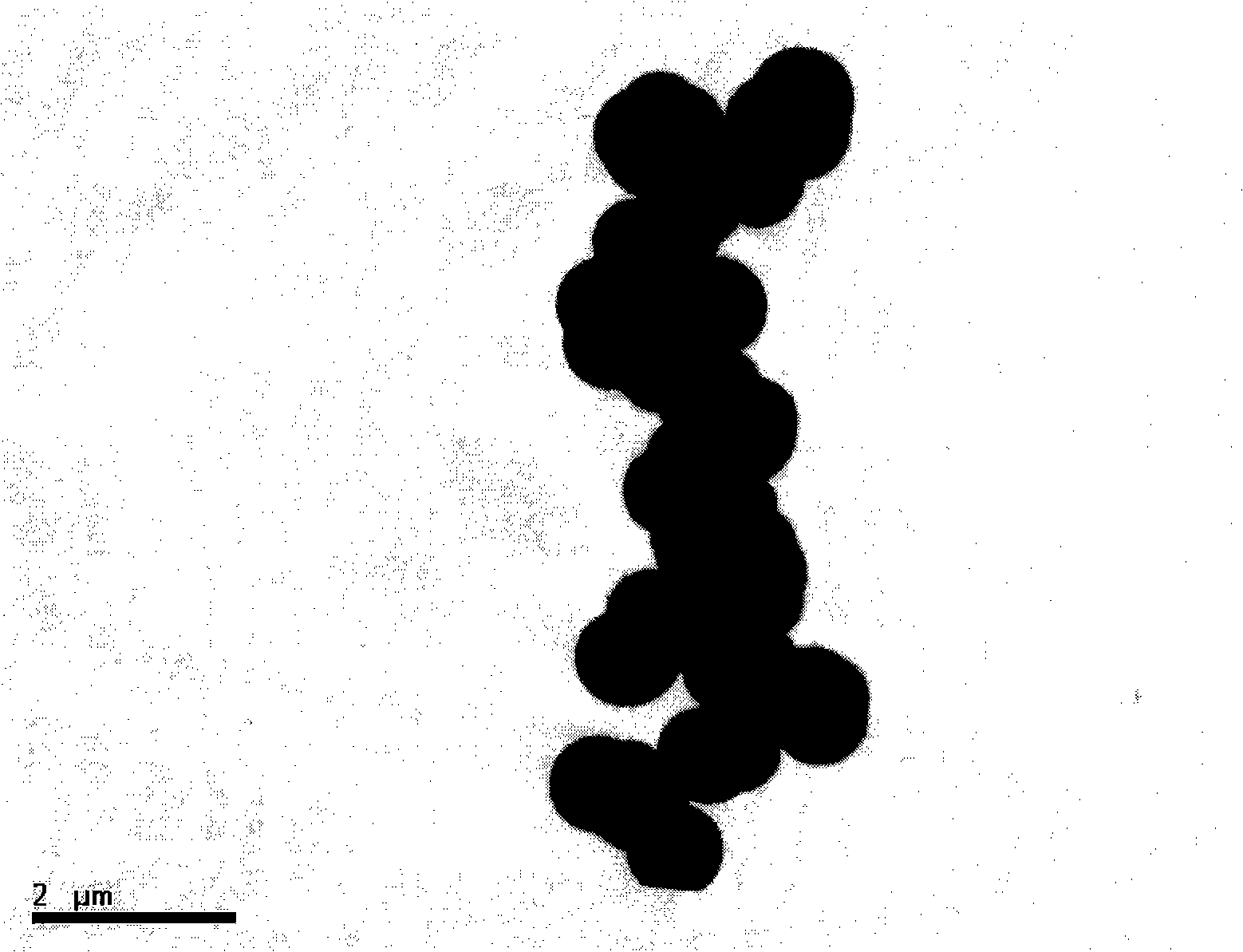

[0056] The product obtained in this example is dispersed in absolute ethanol, and the morphology of the product is characterized by a transmission electron microscope (TEM). image 3 Solid spheres of boeh...

Embodiment 3

[0057] Embodiment three: concrete steps are as follows:

[0058] a. Dissolve 2mmol aluminum nitrate in 20ml deionized water to form a uniformly mixed solution;

[0059] b. Under stirring, add 20ml acetone and mix well;

[0060] c. Under stirring at room temperature, add 0.5 mmol of sodium citrate to the above solution, and continue stirring for 30 minutes to form a uniformly mixed solution;

[0061] d. Transfer the uniformly mixed solution to a hydrothermal kettle, tighten the lid of the kettle, and place it in an oven at 200°C for 24 hours. After the reaction, centrifuge and wash several times with deionized water and absolute ethanol.

[0062] e. Dry the sample obtained in step d at 60° C. for 12 hours to obtain boehmite with a core-shell structure.

[0063] The product obtained in this example is dispersed in absolute ethanol, and the morphology of the product is characterized by a transmission electron microscope (TEM). Figure 4 It can be clearly seen that the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com