LED and manufacturing method thereof

A technology of light-emitting diodes and electrodes, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of complicated manufacturing process and poor yield rate of the manufacturing process, and achieve the effect of improving the light extraction rate and increasing the luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above-mentioned and other objects, features, and advantages of the present invention more obvious and understandable, this specification specifically selects preferred embodiments, accompanied by drawings, and is described in detail as follows:

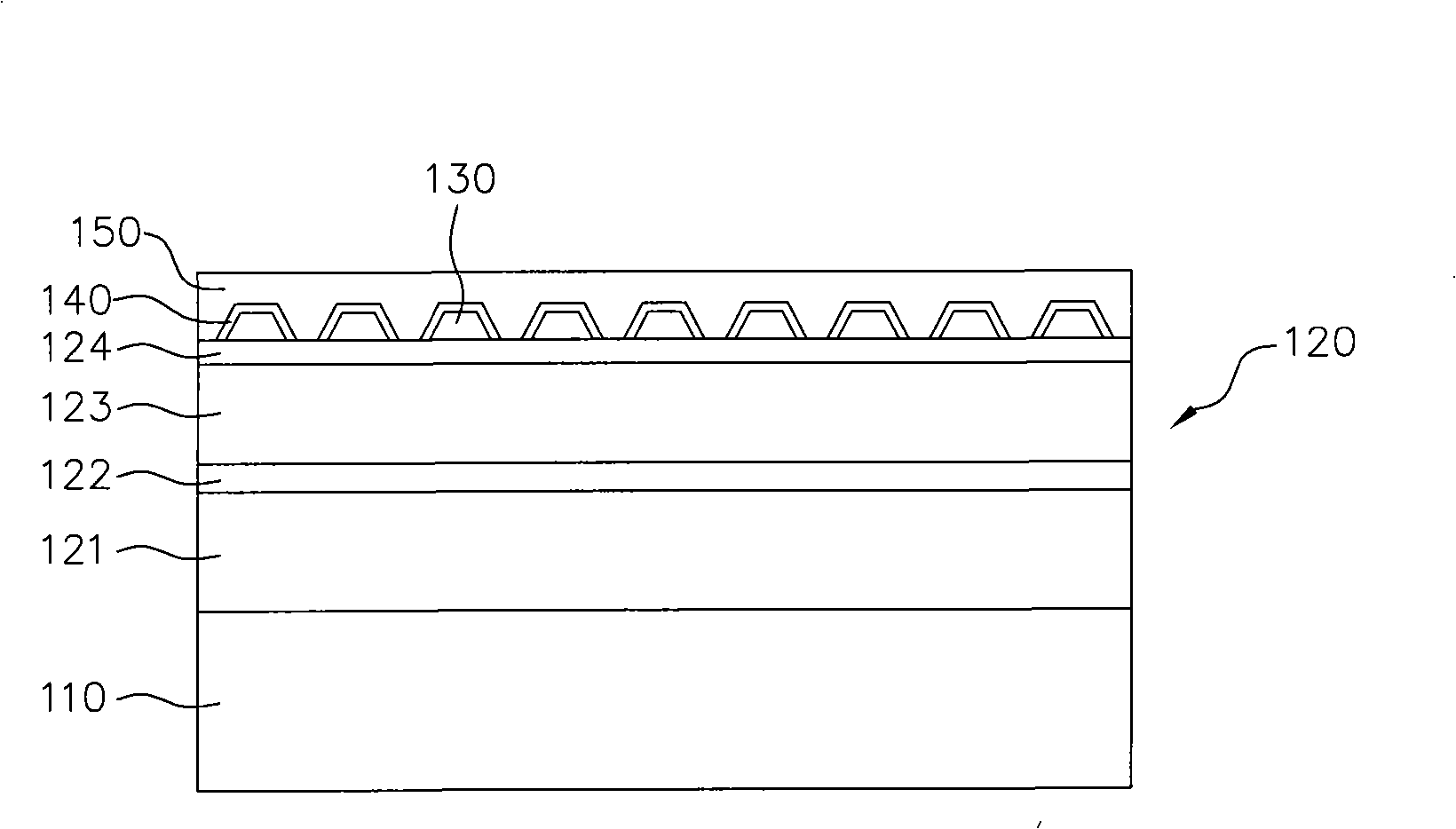

[0016] Please refer to Figure 1A to Figure 1F , Which shows a cross-sectional view of the manufacturing process of the light emitting diode according to the first embodiment of the present invention. The light emitting diode 100 of this embodiment at least includes an epitaxial structure layer 120, a geometric pattern layer 130, a metal reflective layer 140, a bonding layer 150, a permanent substrate 160, a first electrode 170, and a second electrode 180. The bonding layer 150, the metal reflective layer 140, the geometric pattern layer 130 and the epitaxial structure layer 120 are sequentially stacked on the permanent substrate 160. The first electrode 170 and the second electrode 180 are respectively formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com