Method for preparing air bridge using photosensitive subbing

A technology of air bridge and photosensitive adhesive, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of poor controllability of chlorobenzene soaking process, low precision of air bridge, complicated process, etc., to avoid Ultrasonic or chemical corrosion process, protect the body health, reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

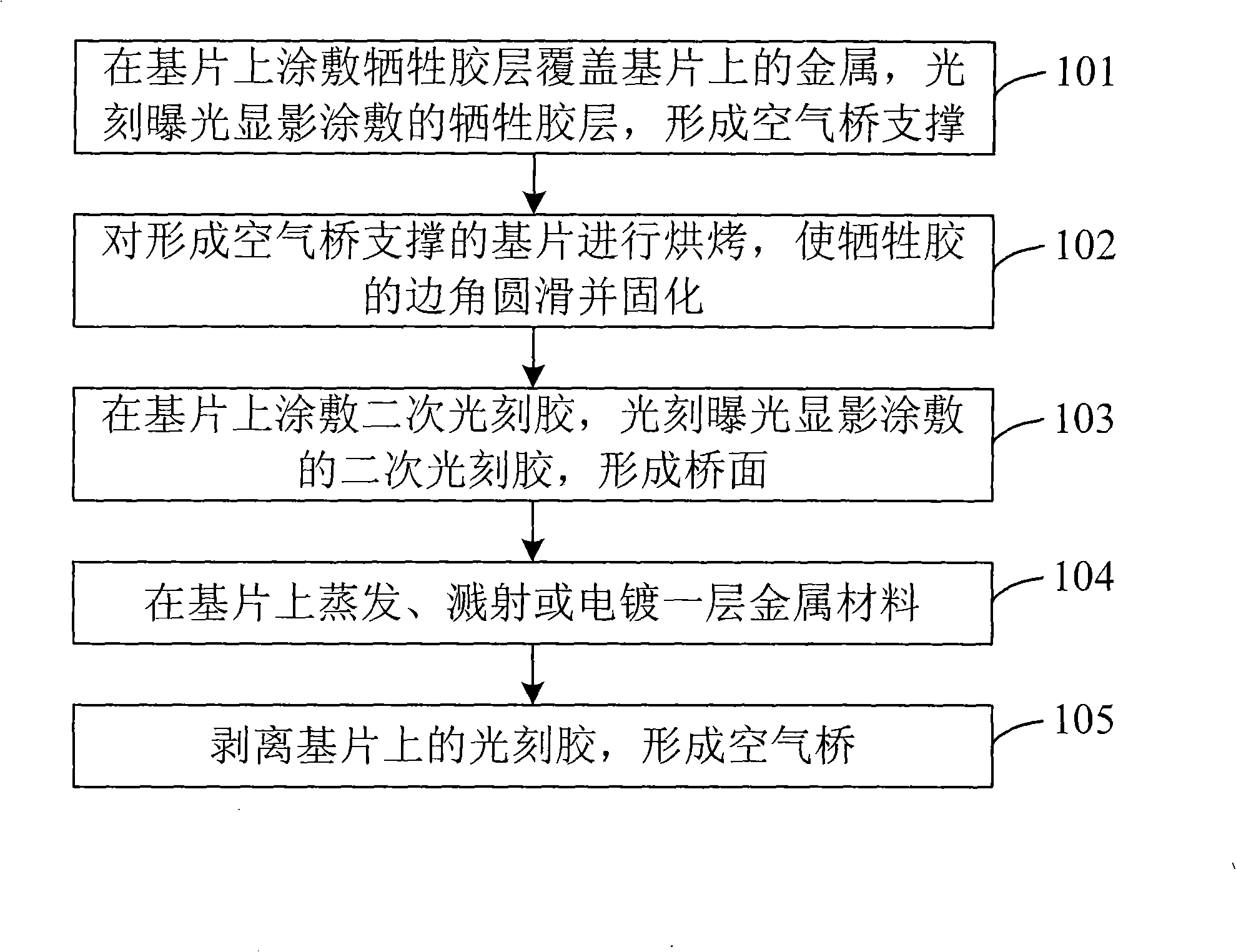

[0052] In this embodiment, 9918 is used as the sacrificial adhesive layer, AZ5214 photoresist is used as the secondary photoresist, and O2 plasma etching is used to remove the residual adhesive. The detailed process method and steps of the present invention will be further described below in conjunction with the specific process schematic diagram 2, and FIG. 7 is a schematic diagram of the process of making an air bridge in the present invention.

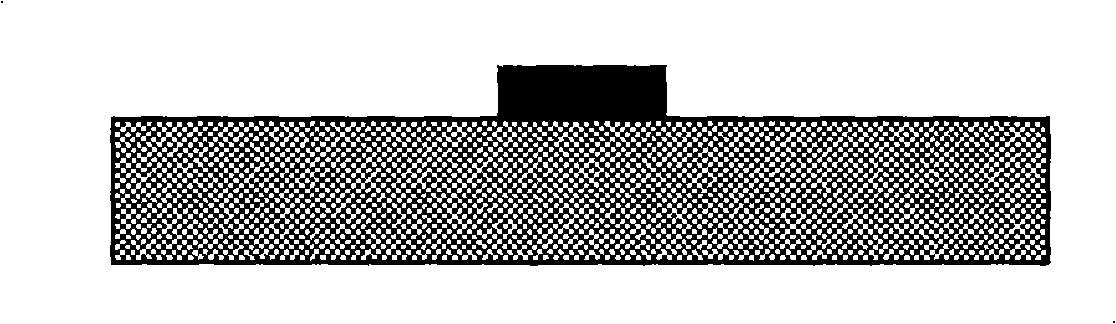

[0053] As shown in schematic diagram a in Figure 2, schematic diagram a is to apply a certain thickness of photoresist 9918 on the substrate to cover the underlying metal, with a thickness of 2.0 μm, and then bake at a temperature of 80 to 100 ° C for 70 to 110 seconds. For example, bake at 90°C for 90 seconds.

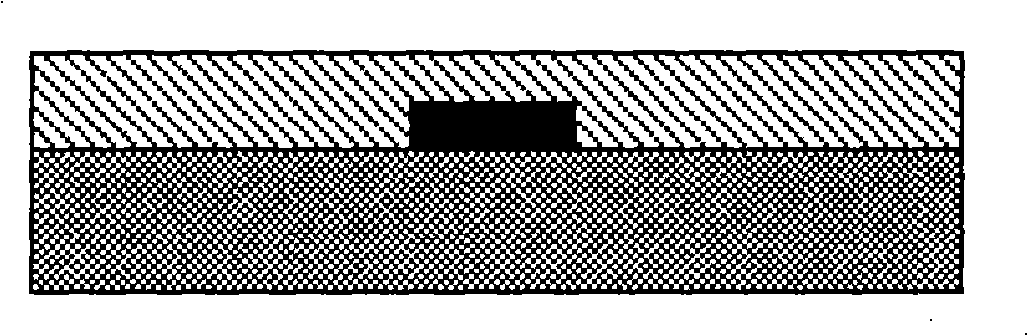

[0054] As shown in schematic diagram b in FIG. 2 , the substrate coated with photoresist 9918 is exposed under an exposure machine; for example, a contact exposure machine or a projection photolithography machine with G, H,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com