Flushing-free centrifugal type differential pressure sealing device for pump

A sealing device, centrifugal technology, applied in parts, pumps, pump components, etc. of pumping devices for elastic fluids, can solve the problems of short service life of seals, low running stability, high contact friction, etc. Achieve the effects of prolonging working life, reducing equipment maintenance and unplanned parking costs, reducing waste and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

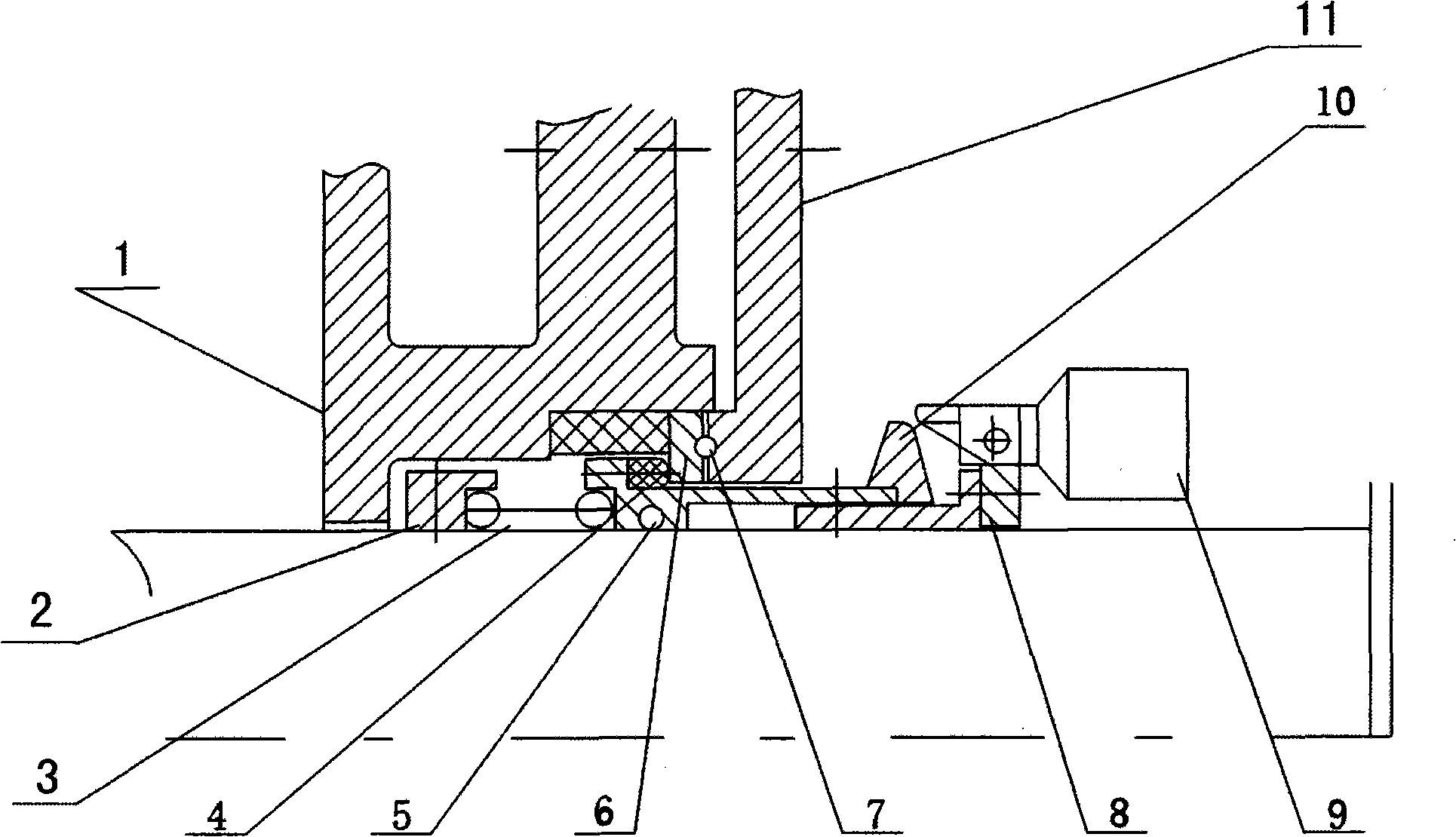

[0019] Such as figure 1 As shown, the stationary ring 6 is fixed in the assembly hole of the pump cover 1, the flying iron seat 8 is fixed on the pump shaft outside the pump cover 1, the rotating ring 4 is set on the flying iron seat 8, and the flying iron seat 8 is formed by the positioning pin. The sliding pair is connected, and the extended end of the rotating ring 4 is connected with a push ring 10 with a slope, and the other end surface of the rotating ring 4 is pressed against the stationary ring 6 when the pump stops. A pair of flying irons 9 are hinged on the flying iron seat 8 , and the force transmission end of the flying irons 9 touches and presses the slope of the push ring 10 . The elastic element 3 is located inside the gland 11. It can be a spring or a bellows. It is installed in the inner cavity of the pump cover together with the elastic element support 2. The elastic element support 2 is fixed on the pump shaft. One end of the elastic element 3 touches the el...

Embodiment 2

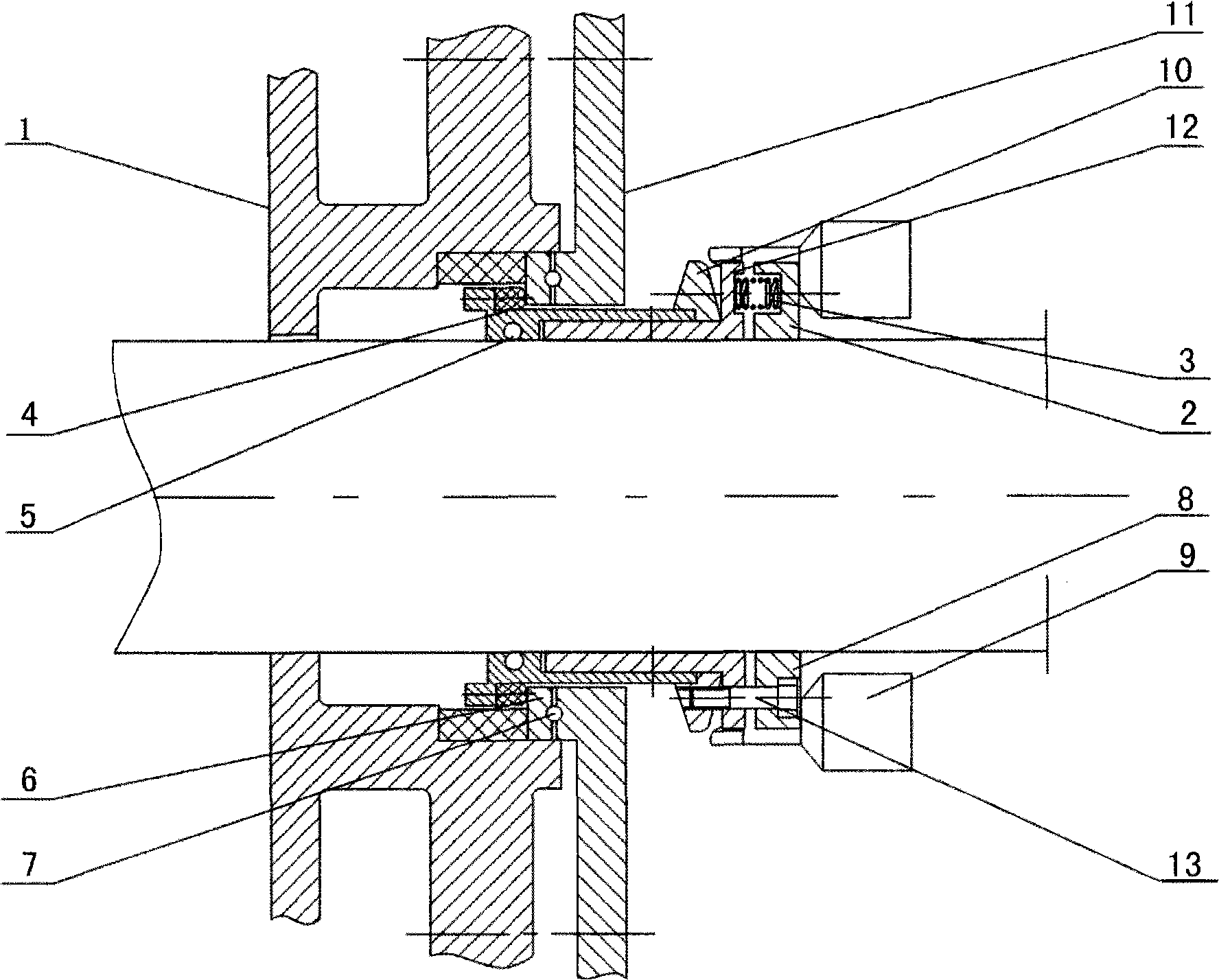

[0021] Such as figure 2 As shown, the stationary ring 6 is fixed in the assembly hole of the pump cover 1, the pressure ring 12 is fixed on the pump shaft outside the pump cover 1, the rotating ring 4 is set on the pressure ring 12, and the positioning pin and the pressure ring 12 form a slip Secondary connection, the extended end of the rotating ring 4 is connected with a push ring 10 with a slope, and the other end face of the rotating ring 4 is pressed against the stationary ring 6 when the pump stops. A pair of flying irons 9 are hinged to the flying iron seat 8 and then fixed on the pump shaft, and the force transmission end of the flying irons 7 touches and presses the slope of the push ring 10 . The elastic element 3 is located outside the gland 13, and can be a spring or a bellows, one end of which is pressed on the pressure ring 12 fixed on the pump shaft, and the other end is pressed on the axially sliding elastic element support 2, the elastic element support 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com