Intelligent door lock controlled by clutch-type motor drive without lodging

A technology of motor-driven control and intelligent door lock, applied in the field of locks, can solve the problems of loss of flexibility, short service life, pulling of inner and outer clutch sleeves, etc., and achieve the effect of fast opening speed, long service life and flexible performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

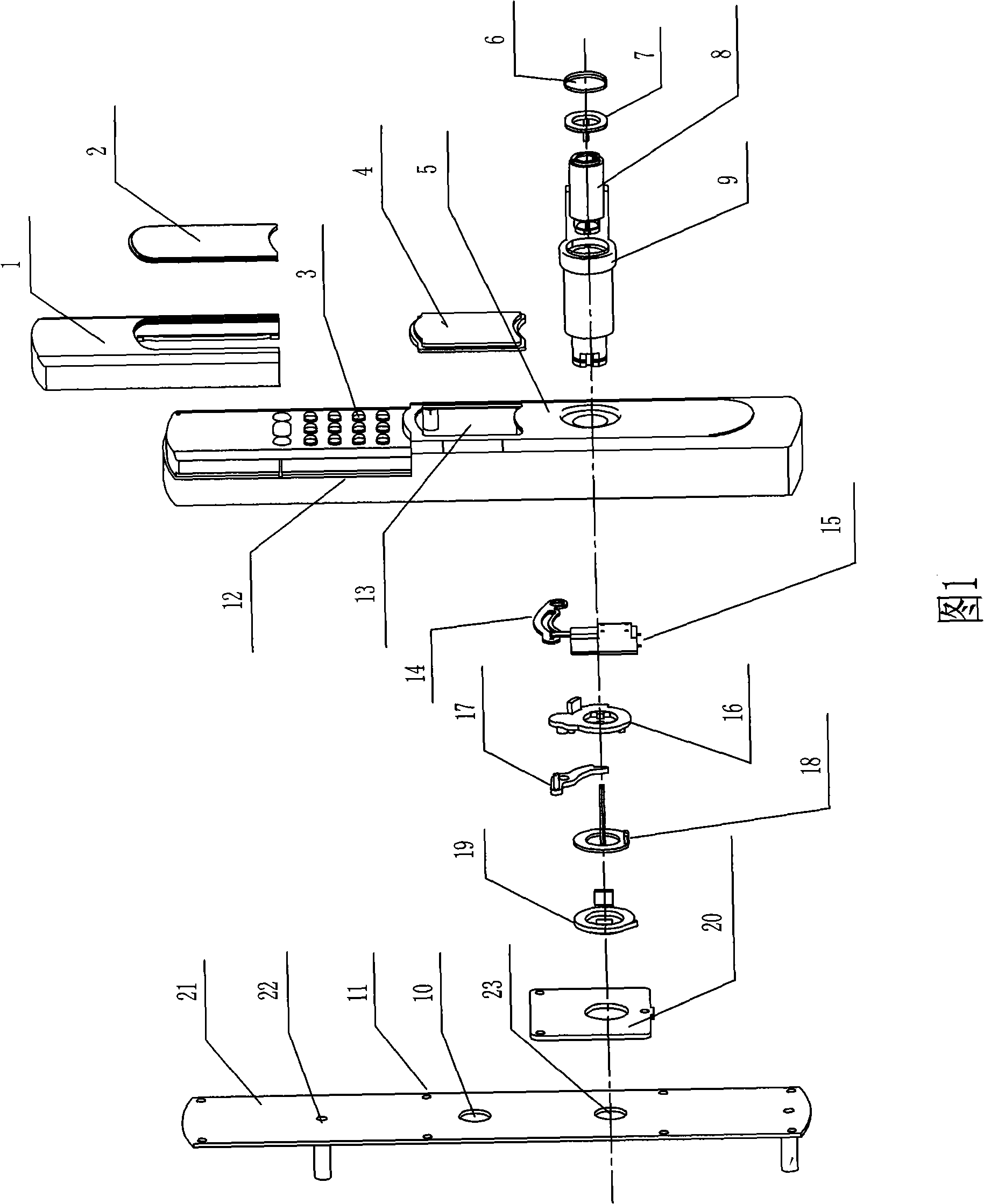

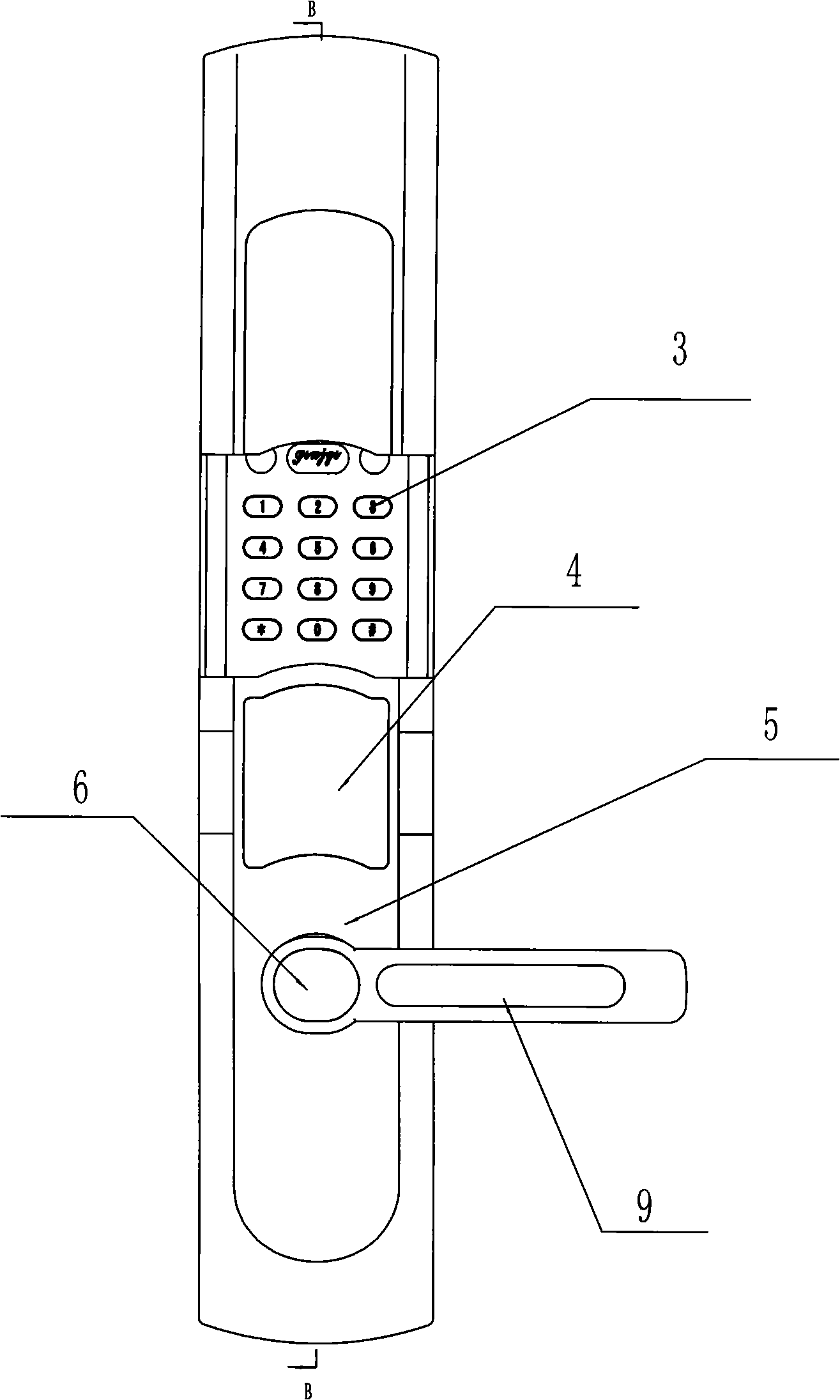

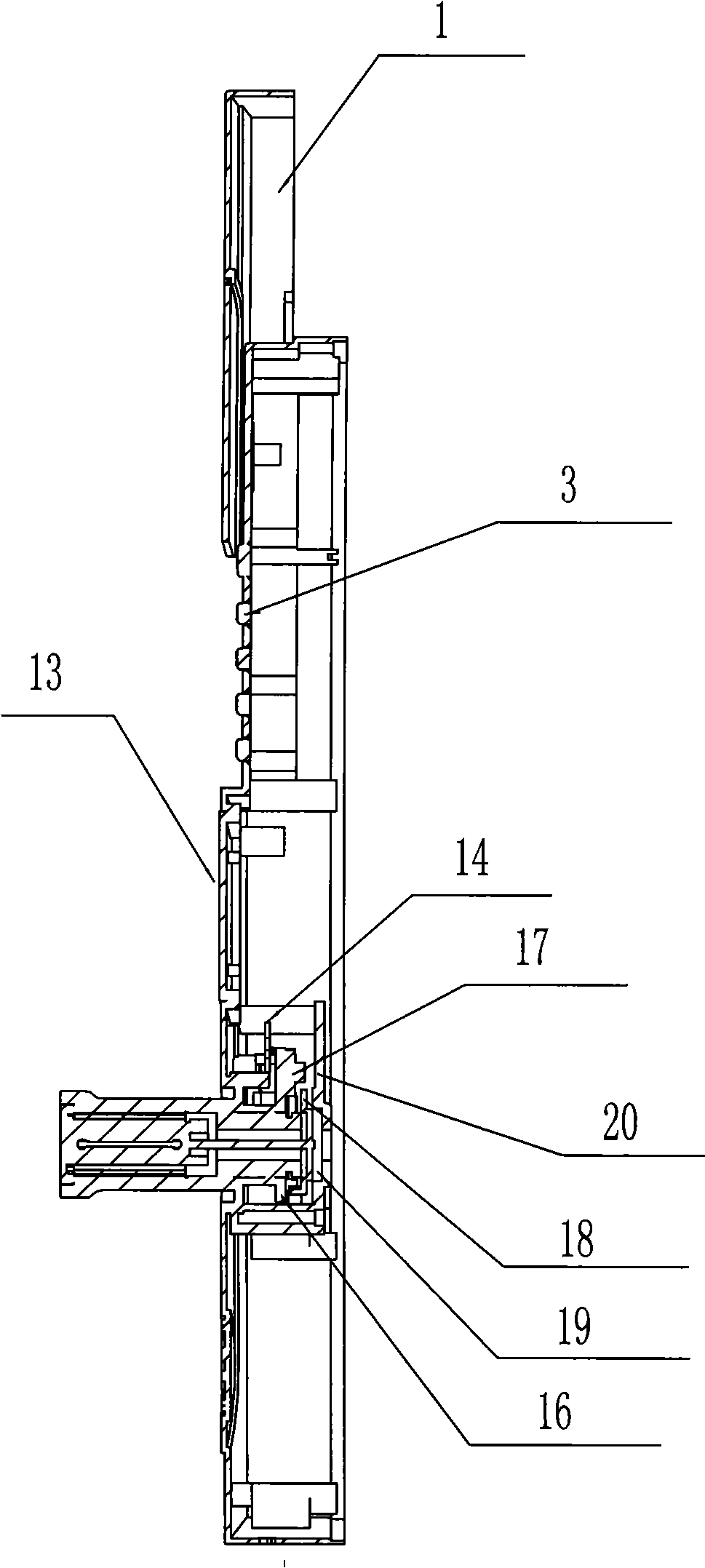

[0021] As shown in the figure: this intelligent door lock controlled by a clutch-free motor drive mainly includes a front panel 5, a handle 9 and a linear telescopic motor 15, and the front panel 5 is provided with a drawer cover 1, a cover 2, and a password. Keyboard 3, induction receiving window 13, chip main board 12 and induction window cover 4, the whole set of device is installed according to the figure and fixed on the front panel 5 through the clutch mechanism fixing plate 20, and the cover plate 21 is provided with signal line hole 10, cover plate The fixing holes 11 and the square bar holes 23 are connected to the front and rear panels through the front and rear panel fixing studs 22 . The shaft of the handle 9 is connected with a handle spline 16, the output shaft of the linear telescopic motor 15 is connected with the motor connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com