Austenitic free-cutting stainless steel

A kind of austenitic stainless steel, high-speed cutting technology, applied in the field of austenitic stainless steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 42 and comparative example 1 to 13

[0172] Alloys having the chemical compositions described in Table 1 and Table 2 were each melted and cast by using a high-frequency induction furnace to obtain 50 kg of ingots. Then, the ingot was uniformly heated, followed by hot forging to form a round bar with a diameter of 24 mm. The round bars thus obtained are then subjected to heat treatment. Heat treatment was performed by leaving the round bar at 1150° C. for 1 hour, followed by cooling with water.

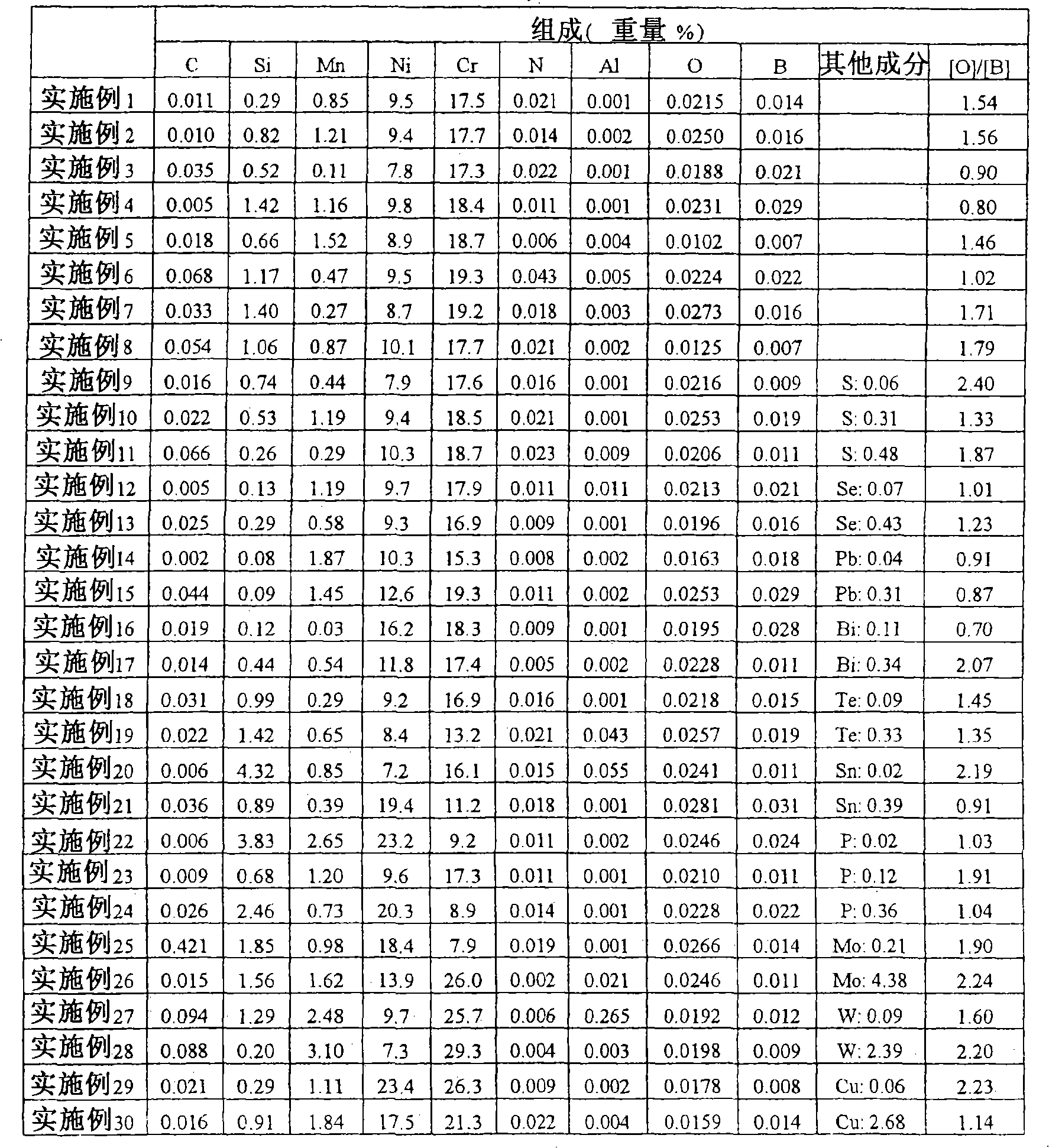

[0173] Table 1

[0174]

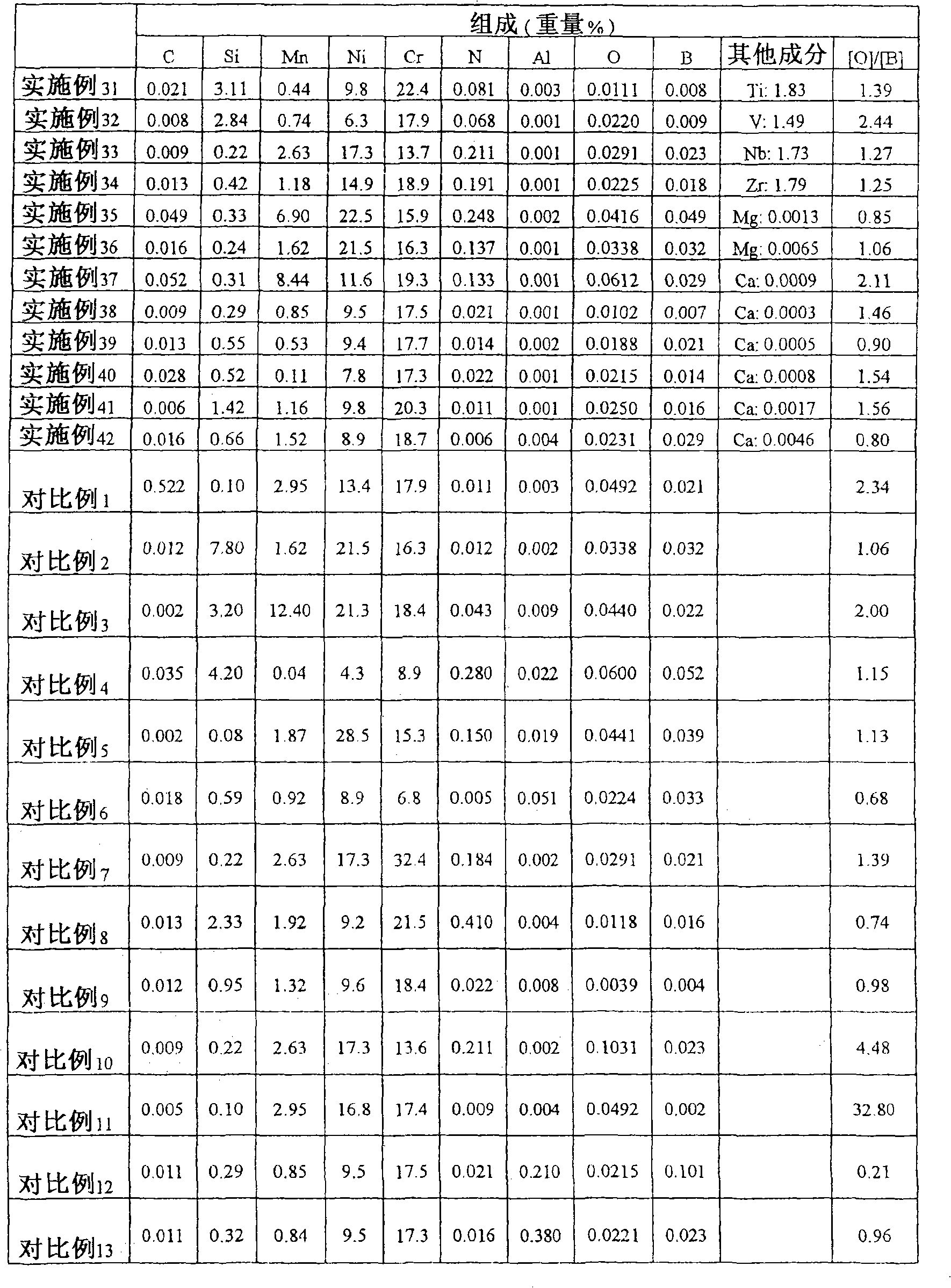

[0175] Table 2

[0176]

[0177] 2. Evaluation(1)

[0178] The resulting round bar was evaluated next.

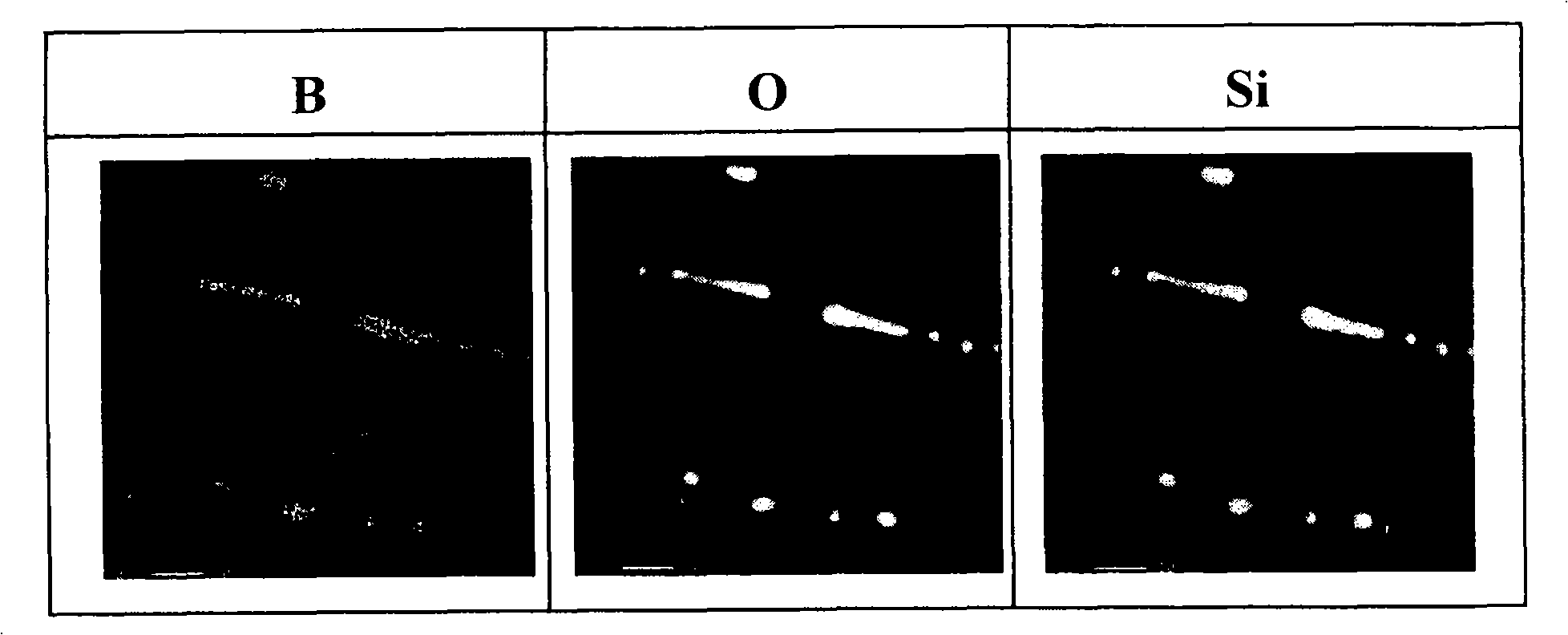

[0179] (1) Composition of inclusions

[0180] After the heat treatment, component analysis was performed on randomly selected oxide samples (30 samples) by using EPMAD. As a result of component analysis, those in which B was confirmed in 15 or more oxide samples are indicated by "A", and those in which B was confirmed in 15 or less oxide samples Den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com